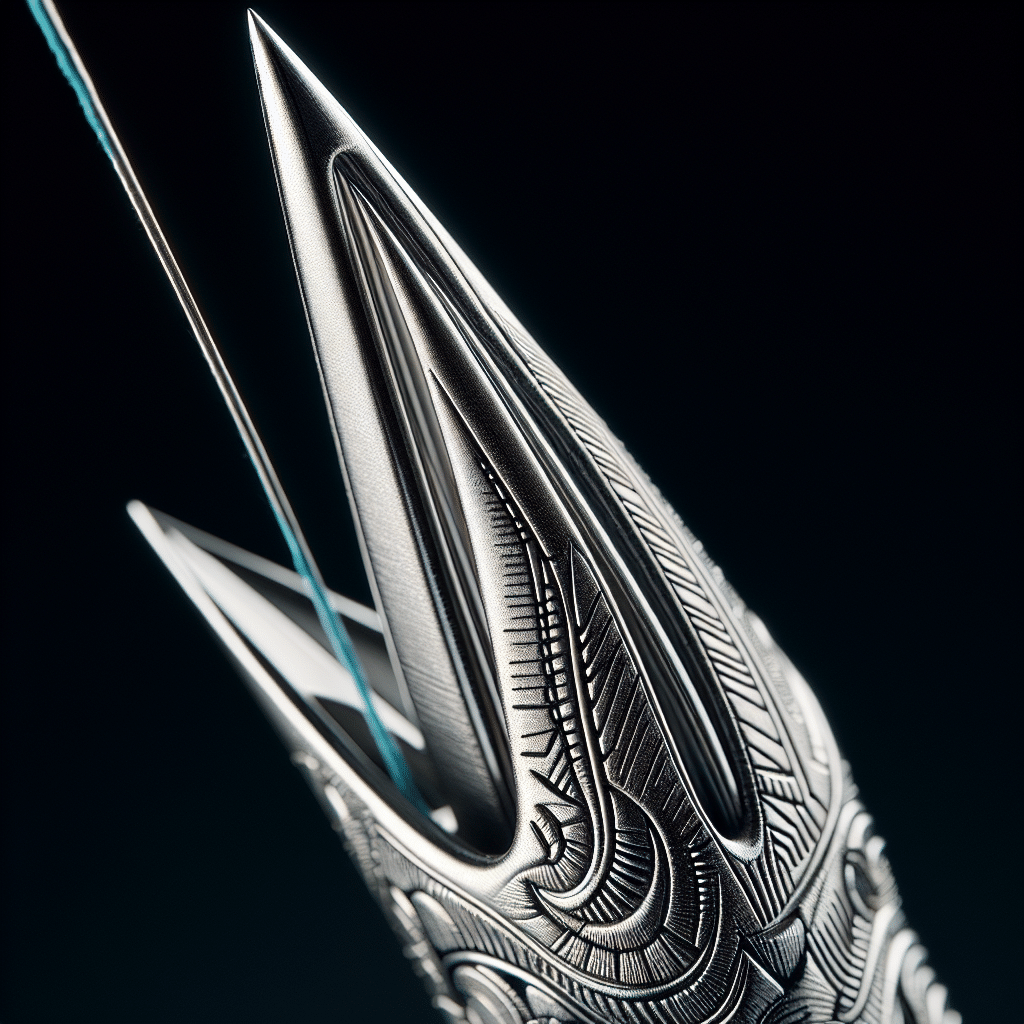

What type of point is used on an industrial overlock? The type of point utilized in an industrial overlock machine is the overlock stitch point, specifically the 3-thread or 4-thread overlock stitches. These stitches are designed to cut and sew the fabric edges simultaneously, providing a secure finish that prevents fraying and ensures durability. The 4-thread overlock is particularly popular for its flexibility and robustness, making it suitable for various fabrics and seam types, from lightweight materials to heavier textiles. This multifunctionality, combined with the ability to adjust tension and stitch width, makes overlock stitches essential for professional garment construction and finishing.

Understanding Overlock Stitches

Overlock stitches, crafted by industrial overlock machines, serve as vital components in garment construction, providing both function and aesthetic appeal. The stitches’ main purpose is to finish raw edges, reducing fraying and enhancing the overall durability of a garment. In this section, we will explore the various types of overlock stitches, their characteristics, and their practical applications.

Types of Overlock Stitches

Overlock machines can typically produce various stitch types, each tailored for specific applications:

- 3-Thread Overlock Stitch: This stitch is commonly used for lightweight fabrics or when a minimal seam finish is required. It features a loop at the back and is best suited for seams that will not be heavily stressed.

- 4-Thread Overlock Stitch: The 4-thread overlock is the most frequently used stitch in commercial sewing. It offers superior strength and is ideal for seam construction on butted edges. This stitch can handle various fabrics, providing flexibility for garment construction.

- 5-Thread Overlock Stitch: Combining the features of a 3-thread overlock and a safety stitch, this option provides enhanced durability. It is often used in heavier garments and for seams that require additional strength.

Components of an Overlock Machine

Understanding how an overlock machine functions aids in grasping the intricacies of the overlock stitch. Here are the primary components that contribute to the stitch formation:

- Needles: Industrial overlock machines typically use two needles to create the stitch formation necessary for a 3-thread, 4-thread, or even 5-thread overlock stitch.

- Looper: A lower looper and an upper looper work together to create the stitch. The upper looper forms the stitch at the front, while the lower looper provides support at the back, completing the stitch loop.

- Tension Mechanism: Correct tension is crucial for stitch integrity. The tension mechanism regulates tension on each thread, ensuring a balanced stitch formation that adapts to different fabric types.

Practical Applications of Overlock Stitches

Overlock stitches have a wide variety of practical applications in garment construction and other textile projects:

Seam Finishing

Overlock stitches are widely recognized for their effectiveness in seam finishing. This helps to prevent fabric fraying and renders a polished, professional finish. For instance, garments made from fabrics like jersey or knit benefit from the stretch and security provided by overlock stitches.

Garment Assembly

Beyond seam finishing, overlocked seams are essential in the overall assembly of garments. The strong nature of the 4-thread overlock stitch allows it to take on the rigors of wear and tear, making it particularly useful for stretchy fabrics used in sportswear or fitted clothing.

Hemming

Overlock stitches are also frequently utilized in creating hems, especially in knit fabrics where a clean, finished edge is required. These stitches allow the fabric to retain its stretchability while providing a neat appearance.

Counterarguments: Limitations of Overlock Stitches

While overlock stitches offer numerous advantages, it is crucial to acknowledge potential limitations:

- Not Suitable for All Fabrics: Overlock stitches may not be appropriate for heavy woven fabrics that require flat, strong seams. In such cases, straight stitches or special seam finishes may be more effective.

- Training Required: Operating an industrial overlock machine can demand specialized skills. Operators must be well-trained in threading, adjusting tension, and maintaining the machine to achieve precise results.

Conclusion

The industrial overlock stitch is a vital component of garment production, providing necessary seam finishes and durability. Its various forms—3-thread, 4-thread, and 5-thread—offer distinct advantages tailored to different applications. Understanding these stitches’ complexities, from their formation to practical applications, is fundamental for anyone involved in garment manufacturing or textile-related endeavors.

FAQs

What is the difference between a 3-thread and 4-thread overlock stitch?

The primary difference lies in the number of threads used. A 3-thread overlock stitch is simpler and ideal for lightweight fabrics, while a 4-thread overlock stitch provides added strength and durability, ideal for medium to heavy fabrics.

Can overlock stitches be used for all fabric types?

While overlock stitches are versatile, they are best suited for knit and stretchy fabrics. Heavier woven fabrics may require alternative finishing techniques to ensure durability.

How do I maintain my industrial overlock machine?

Regular maintenance of an industrial overlock machine includes oiling moving parts, cleaning lint build-up, and checking thread tension. Following the manufacturer’s recommendations for maintenance schedules will help prolong the machine’s life.

Can I adjust the tension on my overlock stitches?

Yes, adjusting the tension is vital for achieving balanced stitches. Each thread typically has an individual tension dial, allowing for customization based on the fabric and stitch type being used.

Is professional training necessary for operating an industrial overlock machine?

While it is possible for beginners to learn basic functions, professional training is highly recommended for efficient operation, as it ensures proper threading, stitch calibration, and machine maintenance.