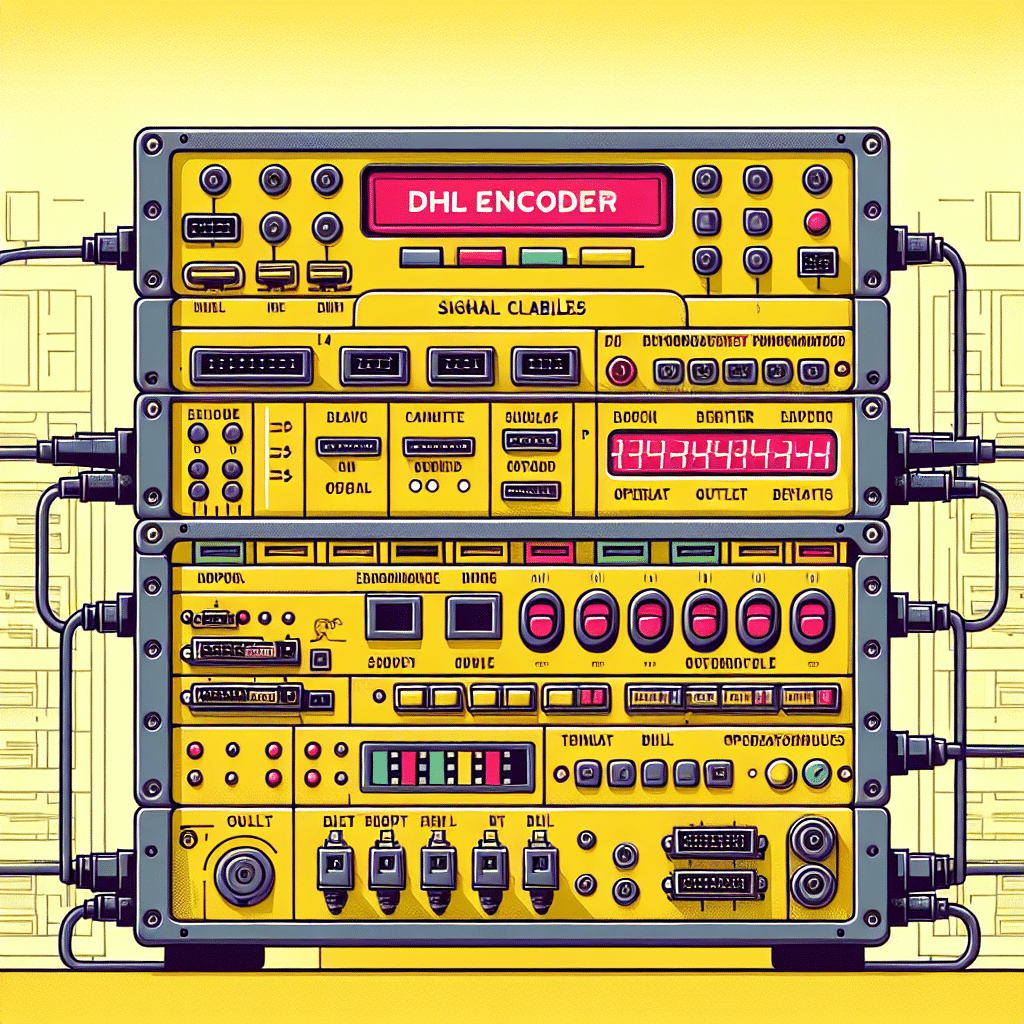

What is a DHL Encoder?

A DHL encoder is a specialized device used to convert physical control signals into digital data that can be processed and transmitted by computer systems. Commonly utilized in automated systems within logistics and supply chain environments, DHL encoders serve crucial roles in warehouse management, inventory tracking, and conveyor systems to ensure operational efficiency. These encoders can be categorized into different types, including incremental and absolute encoders, each with specific applications and capabilities. With advancements in technology, modern DHL encoders often feature intricate designs that enhance precision and reliability, significantly contributing to seamless operations across various sectors. The integration of these devices in logistics not only optimizes workflow but also aids in real-time data collection, ultimately improving decision-making processes.

Understanding DHL Encoders

DHL encoders hold a pivotal position in automated and logistics-based environments. To fully appreciate their importance, we need to delve deeper into what these devices do, their types, applications, and how they align with modern technological innovations.

What is an Encoder?

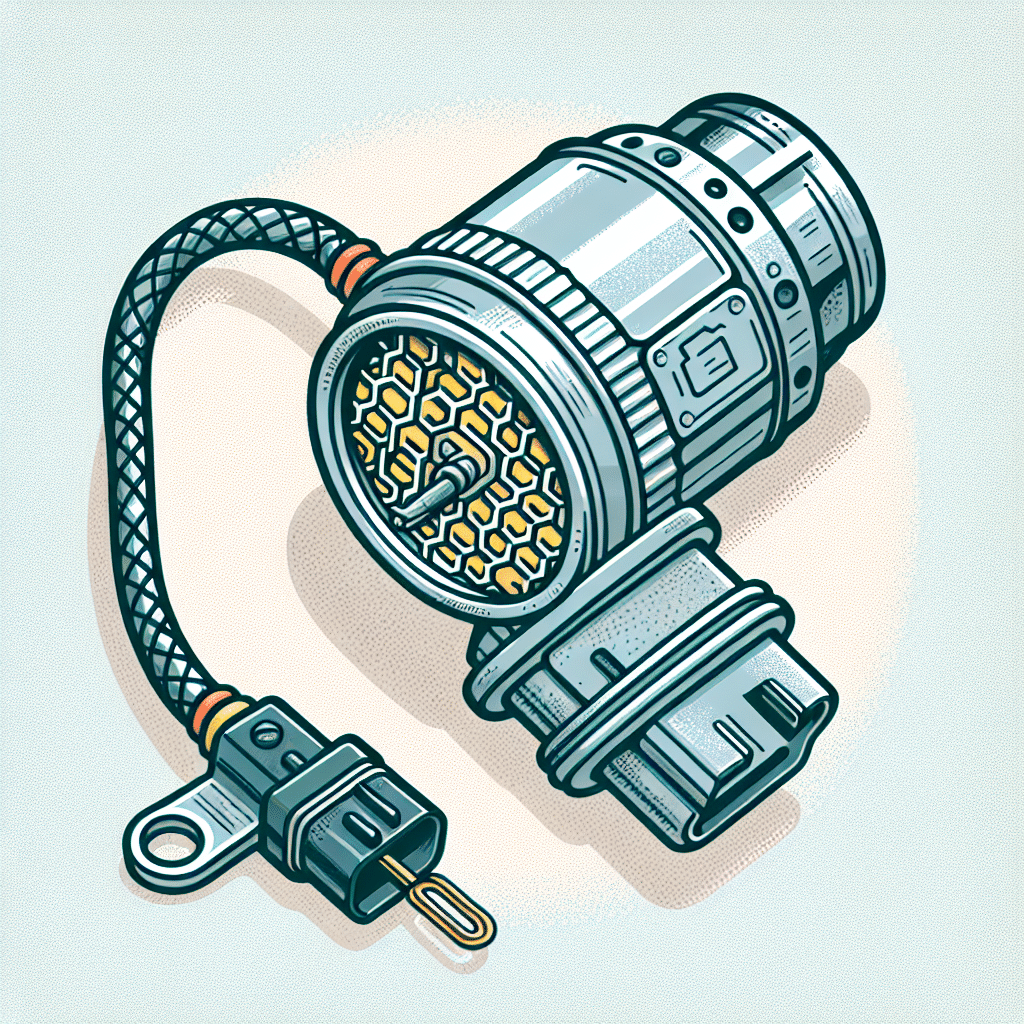

At its core, an encoder is an electromechanical device that converts the position or motion of an object into a format that can be understood by subsequent systems. In the context of a DHL encoder, this typically involves transforming the rotational or linear position of a drive shaft, conveyor belt, or other mechanical components into a digital signal. This digital information can be utilized for control systems, data monitoring, and performance feedback.

Types of DHL Encoders

1. Incremental Encoders

Incremental encoders generate output signals relative to a fixed reference point. When motion occurs, they produce a series of pulses that correspond to the distance traveled or angular rotation. These pulses can be counted and converted into position values, aiding in measuring speed and rotation direction but requiring a reference position to maintain accuracy. Incremental encoders are often favored for applications that demand high-speed feedback and real-time monitoring.

2. Absolute Encoders

In contrast, absolute encoders provide a unique position value that remains consistent irrespective of the power status. Each position is assigned a specific digital code, enabling precise tracking of the object’s location at any given time. This feature is especially advantageous in applications where maintaining positional integrity is crucial, such as in robotic arms and CNC machines.

Applications of DHL Encoders

The innovative use of DHL encoders spans across various industries, primarily focusing on logistics, manufacturing, and automation sectors. Key applications include:

- Warehouse Management: DHL encoders play a crucial role in automated storage and retrieval systems, enhancing the speed and efficiency of inventory management.

- Conveyor Systems: By monitoring the position of items on conveyor belts, DHL encoders ensure that products are sorted and routed correctly within networks.

- Robotics: In robotic systems, encoders provide critical feedback for control mechanisms, helping robots understand their precise position for more accurate movements.

- Manufacturing Processes: In CNC machinery, precise movement tracking is essential, making absolute encoders particularly useful for maintaining defined accuracy in machining operations.

Technological Advancements in DHL Encoders

With technological advancements, DHL encoders are evolving. Innovations include enhanced resolution capabilities, integrated IoT connectivity, and robust designs that improve resistance to environmental impacts. These developments empower businesses to achieve higher levels of automation and efficiency while gaining real-time insights to streamline operations.

Counterarguments: Potential Limitations of DHL Encoders

While DHL encoders bring significant advantages, it’s worth acknowledging the potential limitations. For instance, incremental encoders, although beneficial for high-speed applications, may lose position if the power is interrupted without the presence of a backup system. Conversely, absolute encoders, while providing consistent positioning, can be more complex and costly. Businesses must weigh these factors when integrating encoders into their systems.

FAQs About DHL Encoders

What is the difference between an incremental and an absolute encoder?

Incremental encoders measure changes in position and require a reference point, while absolute encoders provide a unique position value that is retained regardless of power status.

How are DHL encoders used in warehouse management?

In warehouses, DHL encoders are employed in automated storage and retrieval systems to monitor and manage inventory effectively, enhancing operational efficiency.

Can DHL encoders be used in robotics?

Yes, DHL encoders are integral to robotic systems, providing feedback on positioning for accurate movement and performance.

What are the benefits of using DHL encoders in manufacturing?

DHL encoders offer enhanced precision and real-time data tracking, which are critical for maintaining consistent quality and efficiency in manufacturing processes.

Conclusion

DHL encoders are essential components that significantly enhance operational efficiency across various industries. Their ability to convert mechanical motion into actionable digital data supports automated systems in logistics, manufacturing, and robotics, paving the way for a more streamlined and effective approach to management. As technology continues to advance, the role of DHL encoders is expected to expand, further driving innovation in automated solutions.