Introduction to Flanges

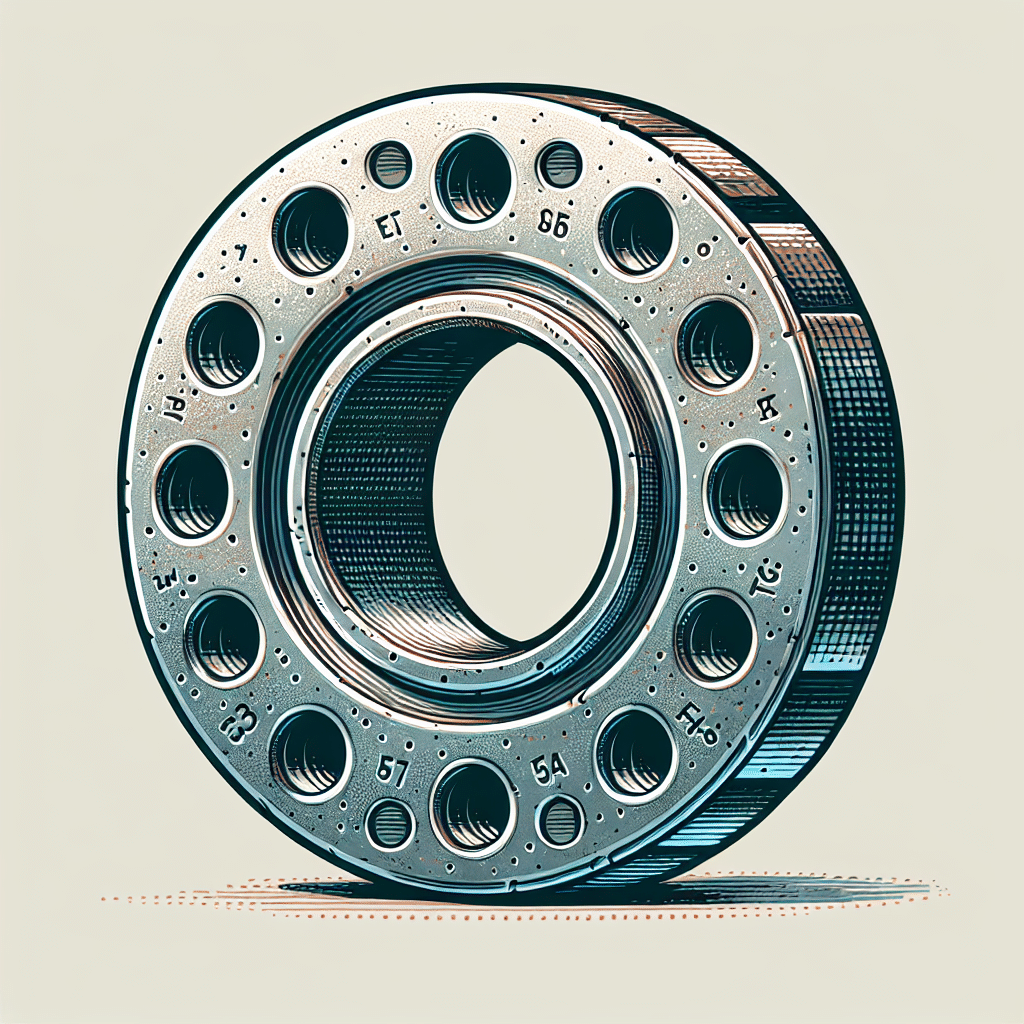

A flange is a mechanical component that connects two sections of piping, allowing for secure and leak-proof joints. Typically made from materials such as steel, plastic, or cast iron, flanges provide a reliable method for creating a seal between the pipes. They come in various types, such as slip-on, weld neck, and blind flanges, each designed for specific applications and pressures. Flanges not only facilitate easy assembly and disassembly of piping systems but also accommodate temperature changes and mechanical stress, ensuring durability and safety in fluid transfer across various industries, including oil and gas, water treatment, and manufacturing. Understanding the role and types of flanges is essential for anyone working with piping systems or related infrastructure.

Understanding Flanges

Flanges serve as crucial components in various mechanical systems, particularly in piping arrangements. They are crucial for creating a secure connection between pipe segments, valves, pumps, and other equipment in a fluid systems. Flanges come in different designs, materials, and pressure ratings, and they play a vital role in ensuring the integrity and efficiency of mechanical assemblies.

Types of Flanges

Flanges can be categorized based on their design and connection method. Below are the most common types:

1. Slip-On Flanges

Slip-on flanges are designed to slide over the pipe ends. They are then welded top and bottom to create a secure joint. These flanges are easy to align and install, making them a popular choice for various applications, especially in low-pressure systems.

2. Weld Neck Flanges

Weld neck flanges have a long tapered neck that provides a stronger connection for high-pressure applications. They are ideal for use in severe service conditions, as they help minimize stress concentration and allow for smooth transitions in flow.

3. Blind Flanges

Blind flanges are used to seal the end of a piping system. They do not have a central opening, making them useful for stopping the flow in a pipeline and allowing for pressure testing. This type of flange provides a critical method for securing system integrity during maintenance.

4. Socket Weld Flanges

Socket weld flanges are used for piping systems that require strong joints. The pipe fits into a socket on the flange, and this assembly is then welded. These flanges are typically found in smaller pipe sizes and high-pressure applications.

5. Lap Joint Flanges

Lap joint flanges are ideal for situations in which frequent disassembly is necessary. They consist of two components: a stub end and a loose flange. The stub end is welded to the pipe, and the loose flange can be rotated, which is advantageous for alignment.

Materials Used for Flanges

The material selection for flanges depends on the application, pressure and temperature conditions, and the fluid being transported. Common materials include:

1. Carbon Steel

Carbon steel flanges are the most widely used due to their strength and resistance to deformation. They are suitable for high-pressure environments but can be susceptible to corrosion if not properly treated.

2. Stainless Steel

Stainless steel flanges are favored for their resistance to corrosion and ability to maintain structural integrity at elevated temperatures. They are commonly used in industries such as pharmaceuticals and food processing.

3. Plastic

Plastic flanges, such as PVC or CPVC, are suitable for low-pressure applications involving corrosive fluids. They are lightweight and resistant to various chemicals, making them ideal for specific industrial applications.

4. Cast Iron

Cast iron flanges are durable and widely used in water and sewage applications. They offer excellent rigidity and strength but may not be suitable for high-pressure systems due to brittleness.

Applications of Flanges

Flanges are utilized across various industries, including:

1. Oil and Gas

In the oil and gas industry, flanges are crucial for connecting pipes and equipment, enabling the transport of hydrocarbons under high pressure and temperature conditions.

2. Water Treatment

Water treatment facilities use flanges to connect various components of their piping systems. Due to their reliability, flanges are necessary for maintaining the integrity of water supplies.

3. Pharmaceutical and Food Processing

Flanges made from stainless steel are commonly used in pharmaceutical and food processing industries, where clean and sanitary conditions are essential.

4. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, flanges are employed to connect ductwork, ensuring the efficient transfer of air through the system.

Installation and Maintenance of Flanges

Proper installation and maintenance of flanges are crucial for ensuring their performance and longevity:

1. Installation

When installing flanges, ensure that the surfaces are clean and aligned. Use appropriate gaskets to create a seal between the flange faces. Tighten bolts gradually in a star pattern to avoid warping or misalignment.

2. Maintenance

Regular inspections are essential to identify signs of wear, corrosion, or leaks. Replace gaskets and tighten bolts as needed to maintain a proper seal. Perform periodic pressure tests to ensure the system’s integrity.

Advantages and Disadvantages of Flanges

Understanding the advantages and disadvantages of flanges can help in making informed decisions when selecting them for piping systems.

Advantages

- Ease of Installation: Flanges facilitate quick and easy assembly and disassembly of piping systems.

- Versatility: Flanges are available in various materials and designs, suitable for different applications.

- Pressure Resistance: Flanges can withstand substantial pressure and temperature changes when installed correctly.

Disadvantages

- Corrosion Risk: Certain materials may corrode over time, requiring regular inspections and maintenance.

- Cost: Depending on the material and design, flanges can be costly, especially in high-performance applications.

Flange Standards and Specifications

Flanges must adhere to certain industry standards and specifications to ensure compatibility and performance. Some of the most notable standards include:

1. ANSI/ASME B16.5

This standard defines the dimensions, tolerances, and pressure-temperature ratings for flanges used in piping systems.

2. ASTM Standards

ASTM standards specify materials and manufacturing processes for flanges, ensuring quality and performance in various applications.

FAQs about Flanges

1. What is a flange used for?

A flange is used to connect two segments of piping, valves, or other equipment, ensuring a leak-proof joint in fluid transfer systems.

2. How do you install a flange?

To install a flange, clean the surfaces, use a compatible gasket, and bolt the flanges together in a star pattern to ensure even tightening.

3. What materials are flanges made from?

Flanges can be made from carbon steel, stainless steel, plastic, and cast iron, depending on the application and conditions.

4. Do flanges require maintenance?

Yes, flanges require regular inspections for wear or leaks and may need gasket replacements and bolt adjustments for optimal performance.

5. What are the different types of flanges?

The common types of flanges include slip-on, weld neck, blind, socket weld, and lap joint flanges, each serving specific functions and applications.

Conclusion

Flanges are indispensable components in various mechanical and piping systems. Their ability to provide strong, leak-proof connections makes them essential for efficient fluid transport across multiple industries. Understanding the different types, materials, and applications of flanges enables professionals to make informed choices that enhance performance and reliability in their infrastructure. Regular maintenance and adherence to installation guidelines are key to maximizing flange longevity and ensuring safety in all operational contexts.