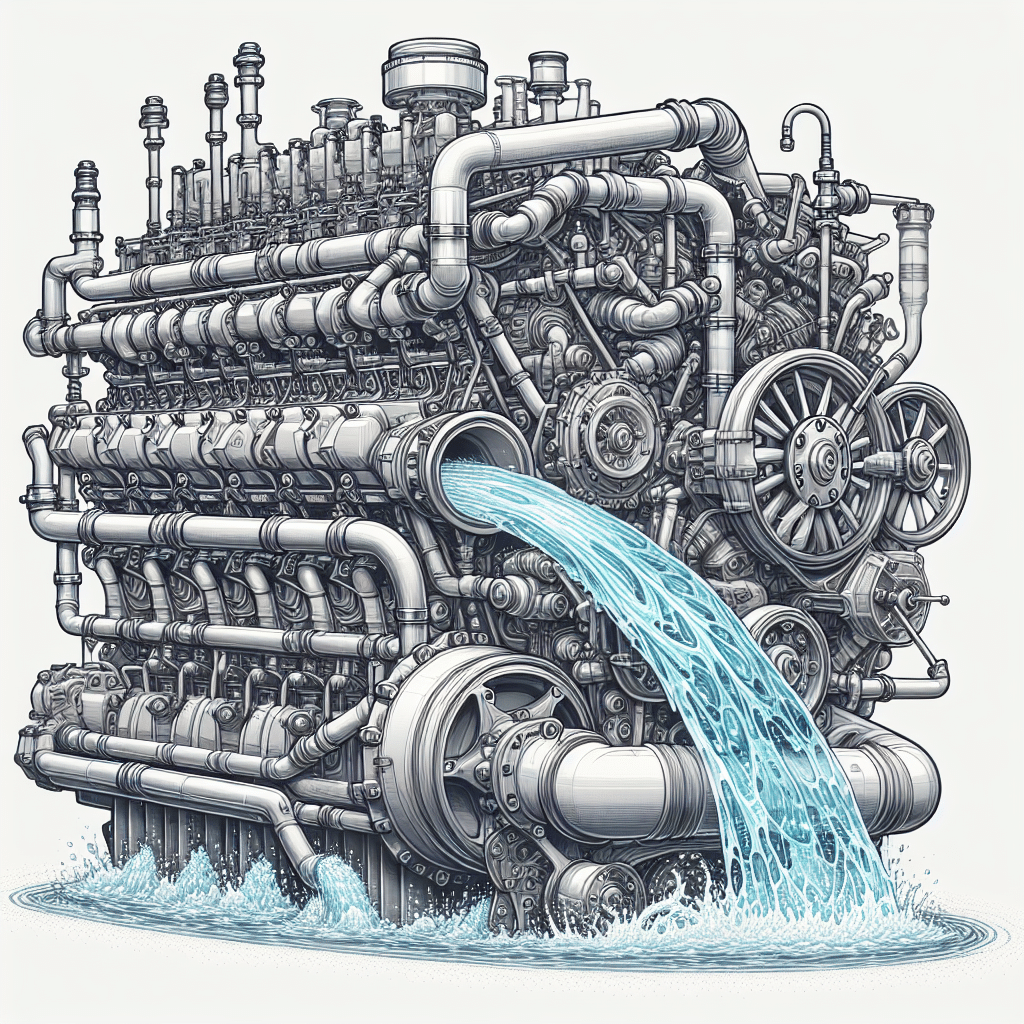

Reversion of water in a marine engine refers to the phenomenon where water flows back into the engine’s combustion chamber or intake system, typically through the exhaust system. This adverse condition can lead to significant operational issues, such as hydro-lock, corrosion, and engine failure. Understanding the mechanics behind reversion is crucial for marine engineers and boat owners to prevent potential damage. Factors contributing to reversion include improper exhaust design, engine cooling mismanagement, and environmental conditions. Proactive measures, such as regular maintenance and appropriate design adjustments, can help mitigate the risks associated with this issue.

Understanding Reversion of Water

The reversion of water in a marine engine is a critical topic that warrants understanding, especially considering the potential damage it can cause. Reversion generally occurs when exhaust pressure, water build-up, or incorrect engine cooling procedures lead to water flowing back into the engine’s combustion system. This situation can arise within various types of marine engines, including inboard and outboard motors.

The Mechanics Behind Water Reversion

To fully grasp the concept, let’s delve into the mechanics involved in a marine engine’s exhaust and intake systems. Marine engines typically expel exhaust gases through an exhaust manifold which is often water-cooled. If there is an interruption in this process or if the water mixes with the exhaust gases, it can create conditions conducive to reversion.

Reversion typically occurs under these conditions:

- Back Pressure: Excessive back pressure within the exhaust system can lead to a situation where water, rather than solely gases, can flow back into the engine. This is particularly common if the exhaust system is improperly designed or blocked.

- Cooling System Failure: If the engine’s cooling system does not function effectively, water can accumulate in the exhaust manifold and, during periods of higher engine pressure or temperature fluctuations, be forced back into the intake.

- Environmental Conditions: Operating in choppy waters or at low RPMs can sometimes exacerbate reversion issues as water can be splashed into the exhaust system.

Consequences of Water Reversion

The consequences of water reversion can be severe. Here are the primary risks:

- Hydro-lock: This is one of the most critical risks associated with water reversion. Hydro-lock occurs when water enters the combustion chamber, preventing the pistons from moving effectively and potentially leading to catastrophic engine failure.

- Corrosion: Water reversion can accelerate corrosion inside engine components, particularly in the exhaust and combustion chambers. This corrosion can significantly shorten the lifespan of marine engines.

- Reduced Performance: The presence of water in the combustion process disrupts the air-fuel mixture, resulting in poor engine performance, misfires, and higher emissions.

Preventive Measures

Given the serious implications that can arise from the reversion of water, it is essential to implement preventive measures. Here are some strategies:

Regular Maintenance

Regular inspections and maintenance can ensure that all components of the marine engine function optimally. Checking the exhaust system for blockages, corrosion, and water accumulation can prevent reversion. Moreover, keeping the cooling systems in good condition ensures they effectively manage water flow.

Proper Exhaust Design

An appropriate exhaust system design will minimize back pressure and facilitate proper drainage. A well-angled exhaust exit designed to prevent water accumulation can significantly reduce the risk of reversion.

Monitoring Engine Performance

Utilizing performance monitoring tools can provide real-time data about engine conditions. Monitoring can catch problems before they escalate, allowing for timely maintenance and adjustments.

Case Studies and Examples

Several marine engineering studies illustrate situations involving water reversion:

- A 2021 incident documented in the Marine Technology Society journal highlighted how an improperly maintained exhaust system on a commercial fishing vessel led to multiple engine failures due to hydro-lock. Regular maintenance would have identified the accumulation of water in the exhaust manifold.

- A study from the International Journal of Naval Engineering analyzed the impact of exhaust system design on reversion prevalence. The findings indicated that vessels with poorly designed exhaust systems experienced a much higher rate of reversion issues compared to those with engineered systems focused on optimal drainage.

Frequently Asked Questions (FAQs)

1. What are the signs of water reversion in a marine engine?

Common signs include unusual engine noises, difficulty starting, poor performance, and visible water in the exhaust. If you notice these symptoms, it’s crucial to inspect your engine immediately.

2. Can water reversion be fixed?

Yes, it can be addressed by identifying the underlying issue, such as a blockage or faulty cooling system. Regular maintenance and proper exhaust design are critical in preventing future occurrences.

3. How does water reversion affect engine warranty?

Water reversion can void manufacturer warranties if it’s determined that improper maintenance or design flaws led to the damage. Always check warranty terms and conditions regarding maintenance obligations.

4. Is water reversion more common in specific types of engines?

While all marine engines can experience water reversion, it tends to be more prevalent in older engines or those with inadequately designed exhaust systems.

5. How can I prevent water reversion in my marine engine?

Regular maintenance, proper exhaust design, and monitoring engine performance are key preventive measures. Always conduct thorough inspections before and after use to catch potential issues early.

Conclusion

Understanding the reversion of water in a marine engine is vital for optimal performance and longevity. By implementing effective maintenance routines, designing exhaust systems carefully, and monitoring engine performance proactively, you can significantly reduce the risk of water reversion and its associated complications. Always stay informed about best practices to ensure the health of your marine engine.