Introduction

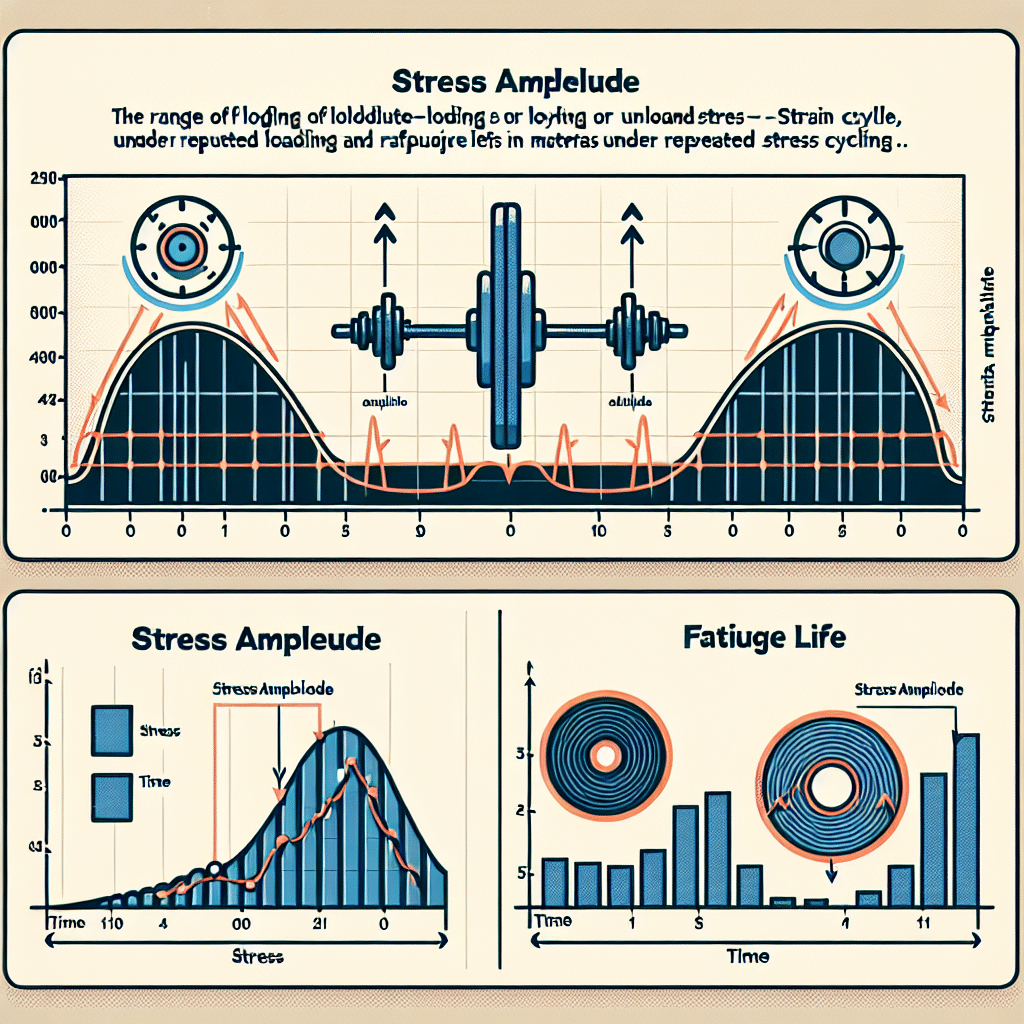

Stress amplitude in fatigue refers to the range of stress experienced by a material during cyclic loading, playing a crucial role in understanding and predicting material failure. It is defined as half the difference between the maximum and minimum stresses applied during a loading cycle. Stress amplitude is vital in fatigue analysis because it helps engineers determine the durability and lifespan of materials under repeated stress. This concept is pivotal in various industries, including aerospace, automotive, and civil engineering, where safety and reliability are paramount. Understanding stress amplitude allows for the design of components that can withstand cyclic loads, thereby preventing catastrophic failures.

Understanding Fatigue and Its Importance

Fatigue is a gradual process that leads to the failure of materials subjected to repeated stress, often at levels lower than the material’s yield strength. This phenomenon can result from various factors, including cyclical loading, environmental conditions, and inherent material properties. The understanding of fatigue is essential for ensuring the longevity and safety of structures, components, and machinery.

The Concept of Stress Amplitude

Stress amplitude represents a critical parameter in the fatigue assessment of materials. The mathematical formulation is expressed as:

Stress Amplitude (σa) = (σmax – σmin) / 2

Where:

- σmax = Maximum stress in the loading cycle

- σmin = Minimum stress in the loading cycle

This equation elucidates how materials respond to alternating stress levels throughout their service life. Higher stress amplitudes generally correlate with reduced longevity due to accelerated fatigue failure.

Factors Affecting Stress Amplitude and Fatigue Life

Several factors can influence stress amplitude and, consequently, fatigue life:

1. Material Properties

The intrinsic properties of materials, such as ductility, toughness, and fatigue strength, significantly impact how they respond to cyclic loading. Metals, polymers, and composites each exhibit unique characteristics that dictate their fatigue behavior.

2. Loading Conditions

Types of loading—such as axial, bending, or torsional—affect stress distribution within the material. Random and repetitive loading scenarios can lead to varying stress amplitudes during the material’s use.

3. Environmental Factors

Corrosive environments, temperature variations, and humidity can accelerate fatigue failure by altering the mechanical properties of materials. Such environmental considerations are crucial for durability assessments.

Fatigue Life and the Role of S-N Curves

To predict fatigue failure, engineers often employ S-N curves (stress-number of cycles curves). These graphs illustrate how varied stress levels affect the number of cycles a material can endure before failure occurs. For each material, a distinct S-N curve exists, establishing a relationship between stress amplitude and fatigue life:

- High-Cycle Fatigue: Typically involves low stress amplitudes and a high number of cycles (greater than 10^4) before failure.

- Low-Cycle Fatigue: Involves high stress amplitudes and fewer cycles (less than 10^4) before failure due to plastic deformation.

Practical Applications of Understanding Stress Amplitude

Comprehending stress amplitude is fundamental in various engineering applications:

Aerospace Engineering

Components in aircraft are periodically subjected to fluctuating loads due to pressure changes and turbulence. Engineers must analyze stress amplitude to ensure safety and reliability.

Automotive Industry

In vehicles, parts like springs and axles experience cyclical loading, making stress amplitude determination crucial for performance improvements and safety enhancements.

Construction and Civil Engineering

Structures such as bridges and buildings must withstand dynamic loads (e.g., wind, seismic activity). A sound understanding of stress amplitude assists engineers in designing structures for longevity and safety.

Counterarguments and Challenges

While assessing stress amplitude is essential for predicting fatigue failure, challenges exist:

1. Complexity of Real-World Conditions

Real-world loading scenarios often vary, complicating stress amplitude calculations. Engineers must account for factors like load history and variable amplitude loading.

2. Material Inconsistency

Inconsistencies in material properties due to manufacturing processes can lead to unpredictable fatigue behavior, highlighting the need for comprehensive testing methods.

Conclusion

Understanding stress amplitude is critical for accurately predicting fatigue life in various engineering applications. By leveraging this knowledge, professionals can optimize designs, improve material selection, and enhance safety across multiple industries. Implementing robust testing and analysis methods further contributes to a comprehensive understanding of material behavior under cyclic loading.

Frequently Asked Questions (FAQs)

What is the relationship between stress amplitude and fatigue life?

The relationship is inversely proportional; higher stress amplitudes generally lead to a shorter fatigue life. This relationship is illustrated on S-N curves, where increased stress corresponds to fewer cycles to failure.

How can stress amplitude be measured?

Stress amplitude can be measured through experimental techniques, such as strain gauges, which monitor the material’s response to applied loads, allowing engineers to calculate stress levels during testing.

What are the consequences of failing to assess stress amplitude properly?

Neglecting to assess stress amplitude can lead to premature material failure, resulting in catastrophic incidents, increased maintenance costs, and potential loss of life in applications such as aerospace and civil engineering.

Are there materials that are more resistant to fatigue?

Yes, materials such as titanium and certain high-performance composites tend to exhibit better fatigue resistance compared to standard steels and alloys. Their inherent material properties contribute to this enhanced performance.