Introduction

Valve stem height is a critical specification in engine design, particularly for high-performance applications where precision matters. In engines such as the LS series used in General Motors vehicles, the height of the valve stem can significantly influence performance characteristics, valve timing, and overall engine efficiency. The valve stem height dictates how far the valve extends into the combustion chamber, affecting the air-fuel mixture’s dynamics and combustion efficiency. A miscalculated valve stem height can lead to improper sealing, decreased power output, or even increased wear and tear on engine components. Hence, it’s essential to understand which engines demand meticulous attention to this specification.

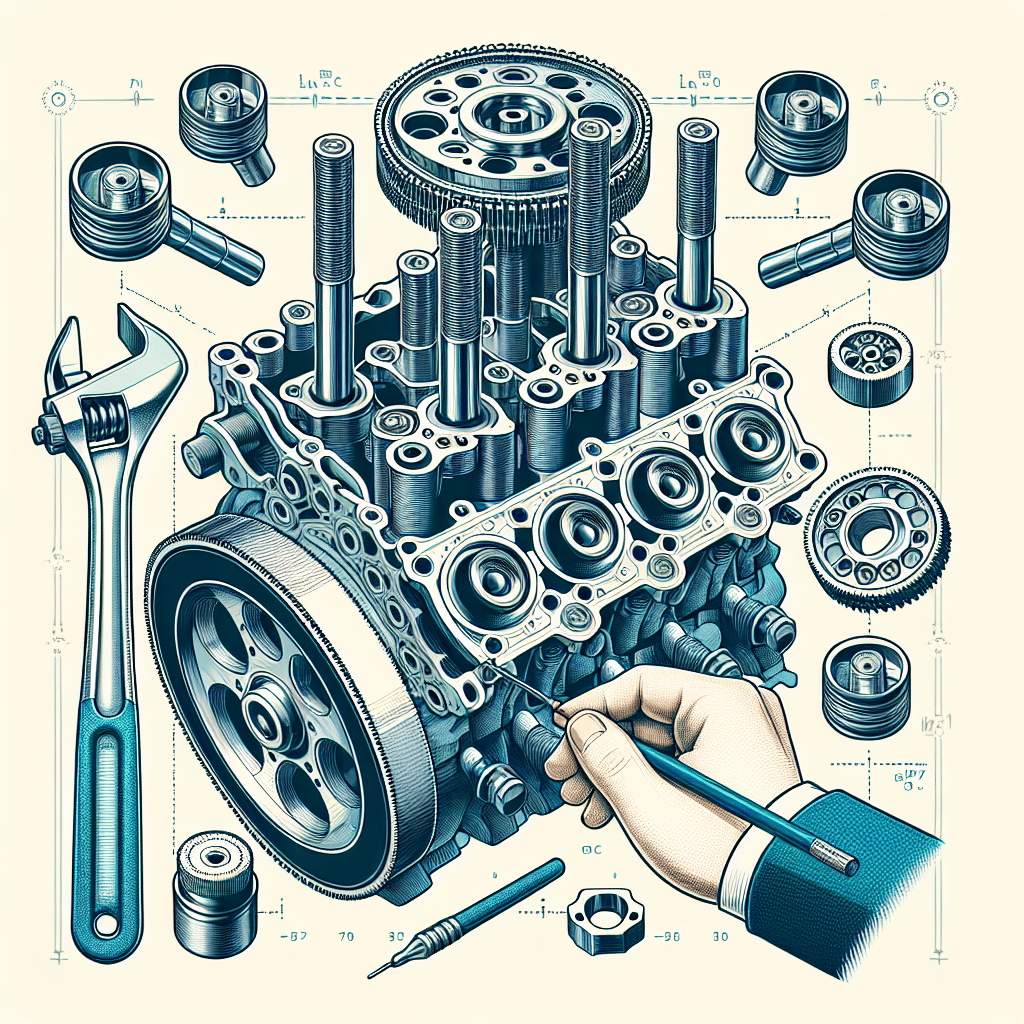

Understanding Valve Stem Height

Valve stem height refers to the distance from the cylinder head to the tip of the valve when it is seated. This measurement is crucial for several reasons, including valve timing, cylinder head design, and combustion chamber efficiency. In essence, the proper valve stem height ensures that the valves open and close at the correct intervals, maintaining optimal performance.

The Importance of Valve Stem Height

In internal combustion engines, valves control the flow of air and fuel into the cylinders and the exhaust gases out. If the valve stem height is not precisely set, it can lead to several complications:

- Performance Issues: Incorrect height can affect the timing and duration of valve opening and closing.

- Engine Wear: Too much or too little clearance can cause excessive wear on the valve seats or leads to valve float.

- Combustion Inefficiency: An improper seal can result in a loss of engine efficiency and power.

Engines Where Valve Stem Height is Most Critical

While all engines require appropriate valve stem heights, certain engines are particularly sensitive due to their design and intended use. Here are a few examples:

1. LS Series Engines

The LS engines, widely used in American muscle cars and trucks, are known for their performance capabilities. Stock configurations allow for significant aftermarket modifications. In these engines, precise valve stem height becomes critical, especially when using high-lift camshafts or modified cylinder heads. An improper height may lead to valve float or inadequate sealing, resulting in reduced performance and longevity.

2. DOHC (Dual Overhead Cam) Engines

Many modern performance engines utilize a double overhead camshaft design. In DOHC engines, the tolerance for valve stem height is very tight, as these engines operate at higher RPMs. Misalignment can disrupt timing, causing issues like loss of power and increased emissions. Manufacturers like Honda and BMW pay close attention to these measurements during the development of their performance lines.

3. High-Performance Racing Engines

Dedicated racing engines often push the limits of engineering. In such applications, even minor variations in valve stem height can lead to catastrophic failures or performance losses. This is particularly true for finely-tuned machines where every component is optimized for peak performance. The need for precise measurements leads many teams to use specialized tools to ensure accurate valve stem height during builds and maintenance.

4. Diesel Engines

In diesel engines, where combustion is controlled by pressure, valve stem height can greatly influence the combustion process. Too high or too low a height can lead to knocking, inefficiency, and increased wear. Manufacturers recommend strict adherence to specifications in diesel applications to ensure optimum operation.

Best Practices for Measuring Valve Stem Height

Ensuring correct valve stem height isn’t just about ensuring the right numbers; it involves thorough testing and precision engineering. Here are some best practices:

1. Use Precision Tools

Employ calipers or gauge blocks specifically designed for measuring valve stems to ensure accuracy.

2. Understand Manufacturer Specifications

Always refer to the manufacturer’s specifications for the engine in question. This ensures that the measurements align with what is designed for optimal performance.

3. Regular Maintenance

Regularly check and adjust valve clearances to maintain optimal height. Over time, wear and thermal expansion can alter the effective height.

4. Professional Assistance

For those uncertain about their ability to measure or adjust valve stem height, consulting a professional mechanic is recommended. Expertise in this field can only boost the engine’s performance and reliability.

Counterarguments and Considerations

While the importance of valve stem height, especially in high-performance engines, is widely recognized, some might argue that advancements in technology have somewhat mitigated these concerns. For example, advanced machining processes and materials may allow for greater tolerances without significant performance loss. Nevertheless, even with technological advancements, the fundamental principles remain unchanged. Proper valve stem height should never be overlooked, as neglecting this foundational aspect can lead to significant long-term consequences.

Conclusion

In summary, valve stem height is especially critical in high-performance engines, such as the LS series, DOHC engines, racing engines, and diesel engines. Ensuring accuracy in this measurement can vastly improve engine performance and longevity. By adhering to best practices and manufacturer specifications, you can maintain optimal engine function and reliability.

FAQ Section

What happens if valve stem height is incorrect?

If the valve stem height is incorrect, it can lead to various engine issues, including valve float, reduced performance, and increased engine wear. It may also cause improper sealing, leading to combustion inefficiencies.

How do I measure valve stem height?

To measure valve stem height, you can use calipers or specialized gauge blocks to get an accurate reading from the cylinder head to the valve tip when seated.

Why are LS engines particularly sensitive to valve stem height?

LS engines are highly modifiable for performance enhancements, making them particularly sensitive to valve stem height as even small discrepancies can affect valve timing and overall engine efficiency.

Can I adjust valve stem height?

Yes, valve stem height can be adjusted by altering the valve seat height or by using shims, but this must be done with great care to align with manufacturer specifications to avoid engine damage.

Is valve stem height the same for all engines?

No, valve stem height varies by engine design and manufacturer’s specifications. Always refer to your engine’s documentation for the correct measurements.