What is 4×8 sheets of HDPE used for? 4×8 sheets of high-density polyethylene (HDPE) are versatile materials widely utilized for various applications due to their robust characteristics. Known for their exceptional strength-to-weight ratio, chemical resistance, and durability, these sheets are ideal for numerous industries, including construction, manufacturing, and food processing. Common uses include backing for signage, construction forms, protective barriers, and in manufacturing products such as containers and pallets. Their easy workability combined with resistance to cracking and UV exposure makes 4×8 HDPE sheets a preferred choice in environments demanding longevity and reliability.

Understanding HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer made from petroleum. It is characterized by its density, with long chains of hydrocarbons leading to fewer branching structures compared to other types of polyethylene. This structure contributes to its rigidity and strength. HDPE is known for several key properties:

- High Strength-to-Weight Ratio: HDPE sheets are lightweight yet highly durable, making them suitable for both structural and decorative applications.

- Chemical Resistance: HDPE is resistant to many chemicals, including acids, alkalis, and alcohols, enabling it to be used in various industrial environments without degradation.

- UV Resistance: When UV-stabilized, HDPE sheets can withstand prolonged exposure to sunlight without significant fading or breaking down.

- Low Moisture Absorption: HDPE has minimal water absorption, making it suitable for wet environments and outdoor applications.

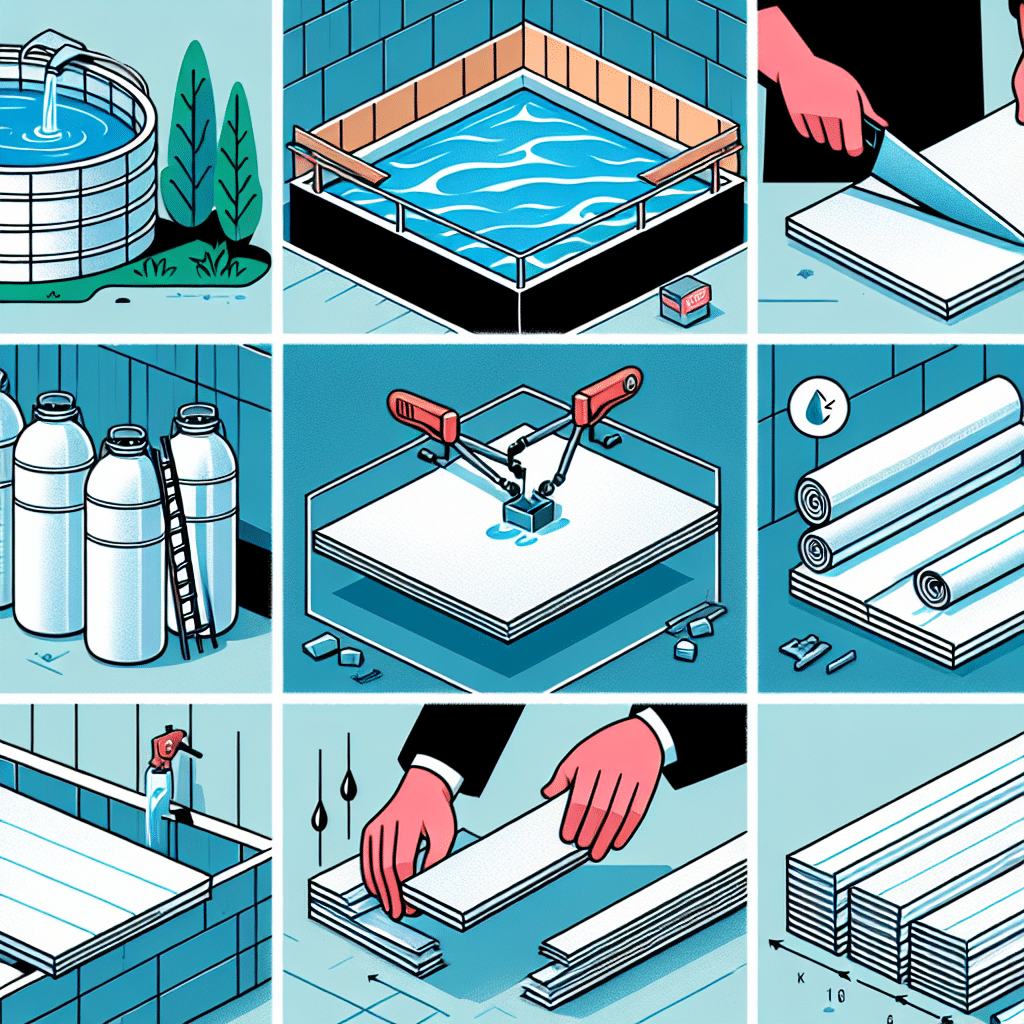

Applications of 4×8 Sheets of HDPE

The uses of 4×8 sheets of HDPE are extensive and varied, justifying their popularity across multiple sectors. Below are the primary applications:

1. Construction and Building Materials

4×8 sheets of HDPE are frequently employed in the construction industry for:

- Wall Panels: HDPE panels serve as durable wall coverings, offering protection against moisture and chemicals in industrial settings.

- Formwork: Their strength and water resistance make HDPE sheets ideal for formwork systems that hold concrete in place.

- Roofing Membrane: HDPE sheets are used as roofing membranes to provide waterproofing and protection from UV exposure.

2. Signage and Displays

In terms of advertising and information provision, HDPE sheets can be used to create durable signs:

- Outdoor Signage: Their UV resistance ensures that signs maintain visibility and remain intact even in harsh weather conditions.

- Atrium and Wayfinding Signs: Lightweight, easy to cut, and work with, HDPE sheets are often used for instructional signs in public places.

3. Manufacturing and Industrial Applications

HDPE’s durability and versatility make it suitable for various manufacturing processes:

- Pallets and Containers: Many companies manufacture pallets and containers from HDPE due to their ability to withstand heavy loads and resist impacts.

- Integrated Packaging: The sheets can also create various integrated packaging structures that benefit from their lightweight and strength characteristics.

4. Food Processing and Safety Equipment

Due to its non-toxic properties, HDPE is utilized in food service applications:

- Food Storage: HDPE containers are common for storing food items in restaurants and food distributions due to their ease of cleaning and chemical resistance.

- Cutting Boards: Many professional kitchens use HDPE sheets as cutting boards because they are easy on knives and can be sanitized thoroughly.

5. Environmental Applications

HDPE is also used in environmental solutions:

- Lining for Landfills: Offering impermeability, HDPE sheets are used as liners in landfills to prevent contaminants from entering the water supply.

- Water and Wastewater Management: Their robustness makes them suitable for systems that manage water and wastewater efficiently.

Advantages of Using 4×8 HDPE Sheets

Choosing 4×8 sheets of HDPE provides several notable advantages:

- Customizable: HDPE sheets can be cut, welded, or fabricated into various shapes and sizes to meet specific project needs.

- Cost-Effective: Due to their durability, they offer a long lifespan and lower maintenance costs compared to alternative materials.

- Eco-Friendly: Many HDPE products are recyclable, contributing to environmentally sustainable practices.

FAQ Section

What is the thickness of 4×8 HDPE sheets?

The thickness of 4×8 HDPE sheets can vary, typically ranging from 1/8 inch to 1 inch. It is crucial to select a thickness that aligns with the specific application requirements.

Are 4×8 HDPE sheets UV resistant?

Yes, many 4×8 HDPE sheets come with UV stabilization, enhancing their longevity when used outdoors by preventing degradation from sunlight.

Can I use HDPE sheets for agricultural purposes?

Absolutely! HDPE sheets are used in agriculture for applications such as ground cover, storage bins, and in the construction of greenhouses due to their resistance to mold and rot.

How should HDPE sheets be cleaned and maintained?

HDPE sheets can be cleaned using standard detergents and soft cloths or sponges. Avoid abrasive cleaners to maintain the surface integrity.

Where can I buy 4×8 HDPE sheets?

You can purchase 4×8 sheets of HDPE from various suppliers including construction materials retailers, plastic suppliers, and specialty stores that focus on plastics and materials for industrial applications.

Conclusion

4×8 sheets of HDPE are a fundamental resource across numerous industries, showcasing versatility and resilience. From construction and signage to food processing and environmental solutions, the applications are vast, with the benefits of strength, durability, and resistance to chemicals and moisture making them an excellent choice for various projects. Whether you’re in manufacturing, construction, or agricultural sectors, utilizing HDPE sheets can optimize your operations and deliver quality results.