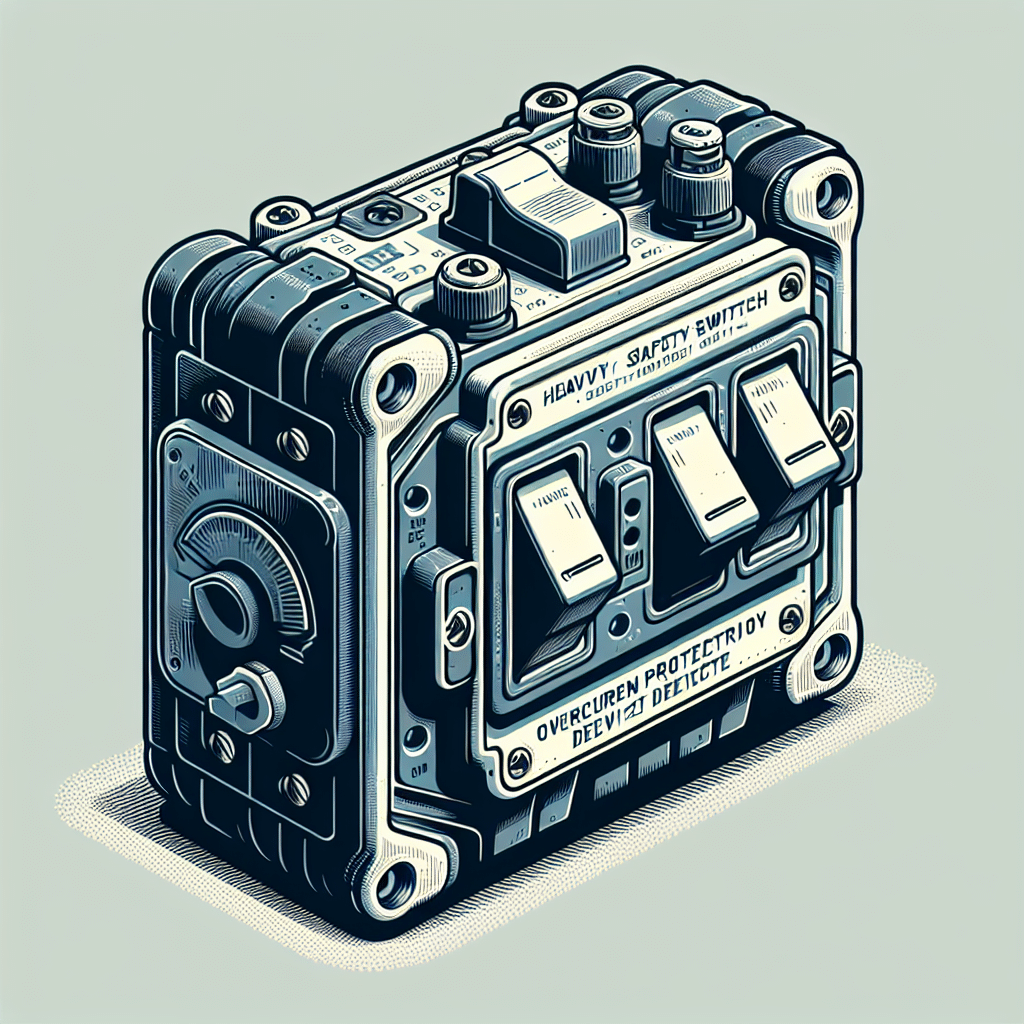

A heavy-duty safety switch is a robust electrical device designed to disconnect power to a circuit in order to prevent electrical hazards or equipment damage. Often utilized in industrial, commercial, and high-demand applications, these switches provide both safety and operational efficiency. Specifically, an Overcurrent Protection Device (OCPD) protects electrical circuits from damage caused by excess current, such as short circuits or overloads. By integrating both functionalities, a heavy-duty safety switch serves as a critical component in safeguarding equipment and ensuring the safety of personnel. In environments where heavy machinery and electrical loads are present, the reliability of these switches is paramount, as they not only contribute to operational safety but also enhance the longevity of electrical systems.

Understanding Heavy-Duty Safety Switches

A heavy-duty safety switch, often referred to as a disconnect switch or a load break switch, is engineered to handle more than typical residential load requirements. It is designed for rigorous environments, delivering enhanced durability and functionality. Typically made from materials such as stainless steel or fiberglass, these switches are capable of withstanding harsh conditions, including extreme temperatures, moisture, and dust. Their robust construction is designed to ensure a long service life and reliability in demanding settings.

Components and Configuration

The construction of a heavy-duty safety switch includes several key components:

- Enclosure: The outer structure that protects the internal mechanisms from environmental hazards.

- Switch Mechanism: This may include various types of operating handles and switches that provide control over power flow.

- Electrical Contacts: These are critical for opening and closing the circuit, and must be made from materials that can handle high current loads.

- Grounding Mechanism: Essential for safety, it provides a path for electrical current to flow safely to the ground in case of a fault.

OCPD: The Overcurrent Protection Device

The Overcurrent Protection Device (OCPD) is an integral feature of many heavy-duty safety switches. OCPDs serve as gatekeepers for electrical circuits, preventing damage from excessive current. This device senses current flow and acts to disconnect the power supply when current exceeds predetermined levels.

There are two primary types of OCPDs:

- Fuses: These devices contain a thin metal strip that melts and breaks the circuit under excess current.

- Circuit Breakers: These can be reset after tripping and come in thermal, magnetic, or dual-function forms, responding to overloads or short circuits.

Applications of Heavy-Duty Safety Switches

Heavy-duty safety switches find applications in various sectors:

- Industrial Facilities: Used to manage heavy machinery operation and protection.

- Commercial Buildings: Essential for systems such as HVAC units and large electrical equipment.

- Manufacturing Plants: Crucial for ensuring operational safety in environments with extensive machinery use.

Benefits of Heavy-Duty Safety Switches

The advantages of implementing heavy-duty safety switches include:

- Safety Assurance: They protect workers and equipment by preventing electrical hazards.

- Operational Reliability: Their robust design ensures dependable function under demanding conditions.

- Longevity: Higher durability reduces the frequency of maintenance and replacements.

Installation and Maintenance

Proper installation is crucial for the functionality and safety of heavy-duty safety switches. Here are essential considerations:

- Location: Position should be easily accessible for operation and emergency use.

- Mounting: Install according to manufacturer specifications, ensuring structural stability.

- Grounding: Adequate grounding is necessary to enhance safety and performance.

FAQ Section

What is the function of a heavy-duty safety switch?

The primary function of a heavy-duty safety switch is to disconnect power to electrical circuits, ensuring protection against overloads and short circuits.

How does an OCPD protect electrical circuits?

An OCPD protects electrical circuits by interrupting the current flow when it exceeds safe levels, preventing potential damage to wiring and equipment.

When should a heavy-duty safety switch be used?

Heavy-duty safety switches should be used in industrial and commercial settings where high current loads are present and electrical safety is paramount.

What maintenance practices should be followed for heavy-duty safety switches?

Regular inspections, cleaning, ensuring proper grounding, and testing operation are recommended maintenance practices for heavy-duty safety switches.

Are heavy-duty safety switches weatherproof?

Many heavy-duty safety switches are designed with weatherproof ratings, making them suitable for outdoor applications. However, it’s essential to check the product specifications.

Conclusion

In conclusion, heavy-duty safety switches integrated with Overcurrent Protection Devices play a vital role in maintaining safety and reliability in electrical systems. Their robust construction, comprehensive functionality, and adaptability to harsh environments make them indispensable in various industrial and commercial applications. Understanding their design, benefits, and maintenance requirements can enhance operational efficiency and safety standards significantly. As electrical systems continue to evolve, incorporating advanced safety devices like heavy-duty switches will be increasingly essential to protect both personnel and equipment.