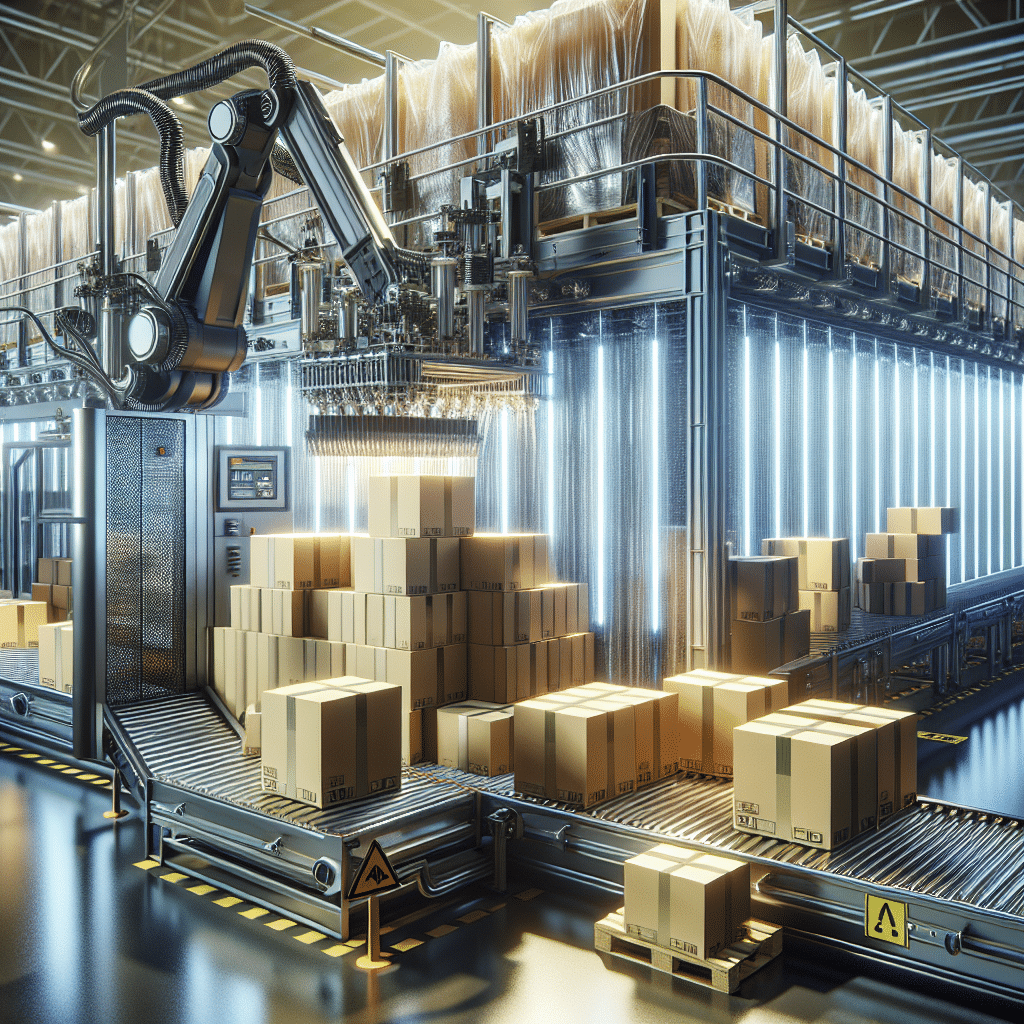

A high-speed in-line palletizer is a sophisticated automation solution designed to efficiently stack products onto pallets in a seamless operational flow. Utilized predominantly in manufacturing and distribution industries, these palletizers align and deposit containers—such as boxes, bottles, or cans—onto a pallet based on predetermined patterns. The ‘high-speed’ designation refers to their capability of handling large volumes of products quickly, often exceeding hundreds of cycles per hour, thereby maximizing productivity and minimizing labor costs.

High-speed in-line palletizers operate in conjunction with conveyor systems and can be configured for various load sizes and weights, making them versatile for diverse packaging shapes and materials. Their integration with robotics, sensors, and advanced control systems ensures precision in product handling while maintaining high safety standards. This technology significantly reduces the manual labor involved in the palletizing process, enhances operational efficiency, and ultimately contributes to a more streamlined supply chain.

1. Introduction to High-Speed In-Line Palletizers

In today’s fast-paced manufacturing landscape, automation and efficiency stand as pillars of operational success. High-speed in-line palletizers present an invaluable solution for industries aiming to enhance productivity and streamline their material handling processes. In this section, we will explore the fundamental components, advantages, and operational principles of high-speed in-line palletizers.

2. What is a High-Speed In-Line Palletizer?

High-speed in-line palletizers are automated machines that efficiently stack products onto pallets in a continuous production line. They are specifically engineered to operate at high throughput rates, enabling businesses to manage increased product demand without sacrificing accuracy or safety.

Unlike traditional palletizers, which may require manual intervention or time-consuming setups, high-speed in-line palletizers leverage advanced technology for precision and efficiency. These machines are capable of processing a variety of products, including bags, boxes, and bottles, making them ideal for various industries, such as food and beverage, pharmaceuticals, and consumer goods.

3. Key Components of High-Speed In-Line Palletizers

To understand the operational effectiveness of high-speed in-line palletizers, it is essential to identify their key components:

- Conveyor Systems: These transport products from production lines to the palletizer, ensuring a smooth flow of materials.

- Pallet Dispenser: Automatically feeds pallets into the palletizing area as needed, maintaining constant availability and efficiency.

- Product Distribution Units: These systems organize and direct products into predetermined patterns before stacking.

- Stacking Mechanisms: Main components that pick and place products onto pallets with precision and speed—typically through robotic arms or mechanical pushers.

- Control Systems: Advanced software and hardware that manage the entire operation, ensuring synchronization between various components.

4. Advantages of High-Speed In-Line Palletizers

High-speed in-line palletizers offer several benefits that make them an attractive choice for modern manufacturing:

- Increased Throughput: Capable of processing hundreds or thousands of products per hour, they effectively meet high demand levels.

- Labor Cost Reduction: Automation minimizes the need for manual labor, leading to significant savings in labor costs and reducing the risk of injuries.

- Enhanced Accuracy: Precision in stacking patterns leads to better load stability during transportation and storage.

- Flexible Configuration: High-speed in-line palletizers can adapt to various product shapes and sizes, making them suitable for diverse operations.

- Improved Safety: Automation reduces human intervention, lowering the risk of workplace accidents.

5. How High-Speed In-Line Palletizers Work

The operation of high-speed in-line palletizers can be broken down into several key steps:

- Product Arrival: Products are transported via conveyor systems to the palletizer site.

- Orientation and Distribution: Machines automatically orient the products to their correct positioning before entering the stacking area.

- Stacking: The stacking mechanism works rapidly to pick and place products onto the pallet according to specified patterns.

- Pallet Transport: Once stacked, pallets are moved to staging areas or shipping docks for distribution.

6. Applications Across Industries

High-speed in-line palletizers are employed across various sectors, demonstrating their adaptability:

- Food and Beverage: Used for packing boxes of cereals, cans, bottles, and other food packages.

- Pharmaceuticals: Essential in stacking pharmaceutical products securely and accurately for distribution.

- Consumer Goods: Effective in handling packaging for personal care products, household goods, etc.

- Logistics: Streamlining the warehousing process and improving throughput.

7. Selecting the Right High-Speed In-Line Palletizer

When considering the implementation of a high-speed in-line palletizer, businesses should assess key factors:

- Product Range: Evaluate the variety of products being handled, including their dimensions and weight.

- Throughput Requirements: Determine the required output speeds based on demand levels.

- Space Constraints: Consider the available floor space and the required layout for an efficient operation.

- Integration Capabilities: Ensure compatibility with existing machinery and systems.

8. FAQs About High-Speed In-Line Palletizers

Q1: How fast can a high-speed in-line palletizer operate?

A high-speed in-line palletizer can typically handle anywhere from 20 to 200 products per minute, depending on the specific model and configuration.

Q2: What types of products can be palletized?

A variety of products can be palletized, including boxes, bags, bottles, and containers. The design can often be tailored to accommodate specific shapes and sizes.

Q3: Are high-speed in-line palletizers safe to operate?

Yes, these machines are designed with safety features to reduce risks, including emergency stops, protective barriers, and safety interlocks.

Q4: Do high-speed in-line palletizers require special maintenance?

Regular maintenance, including inspection and cleaning of components, is necessary to ensure optimal performance and extend the life of the equipment.

Q5: Can high-speed in-line palletizers be customized?

Yes, many manufacturers offer customization options to meet specific operational needs and requirements, such as changing stacking configurations and improving throughput capabilities.

9. Conclusion

High-speed in-line palletizers represent a vital advancement in industrial automation, offering businesses a means to enhance efficiency and productivity while reducing operational costs. Understanding their function, advantages, and applications will empower organizations to leverage these cutting-edge machines effectively. As industries continue to evolve, adopting high-speed in-line palletizers will become increasingly important in maintaining competitive advantage in a global marketplace.