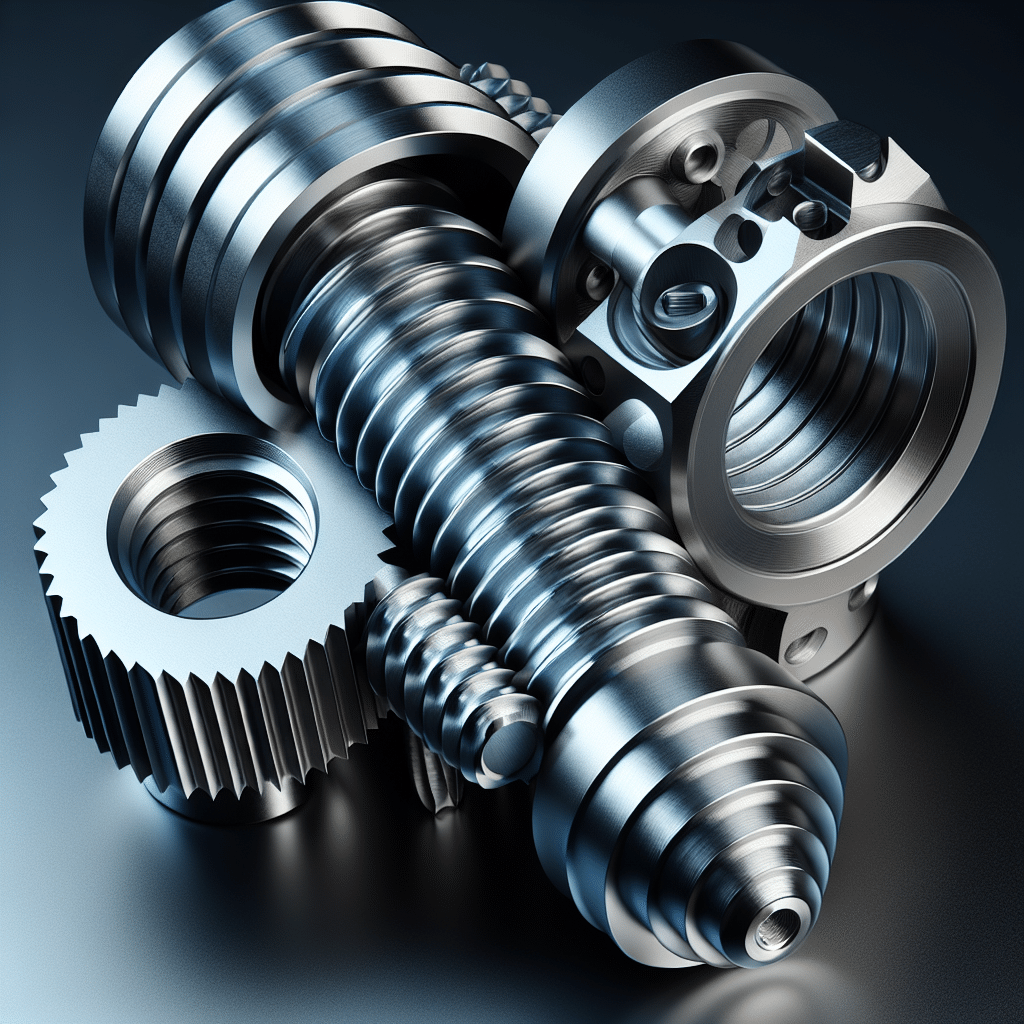

In automotive engineering, the terms “screw” and “hole” refer to critical components in the construction of vehicles. A screw is a fastener characterized by a helical ridge, known as a thread, which allows it to secure objects together by being twisted into a hole. The hole is essentially a cylindrical space that receives the screw, enabling effective fastening and stability in various applications within the automotive structure. Understanding the relationship between screws and holes is vital for ensuring the integrity and safety of automotive designs, particularly when dealing with engine assembly and component attachment.

Understanding Screws in Automotive Engineering

Screws are essential fasteners within automotive engineering, employed to secure components while allowing for ease of assembly and disassembly. They come in various designs, sizes, and materials, each suited for specific applications. Here are some key attributes that define automotive screws:

- Thread Type: In automotive applications, common thread types include UNC (coarse threads), UNF (fine threads), and metric threads. The choice largely depends on the forces being applied and the materials being fastened.

- Material Composition: Automotive screws are often made from alloy steel, stainless steel, or specialized materials that must withstand high temperatures and corrosive environments.

- Head Styles: The head of a screw may vary (e.g., hex, slotted, or Phillips) depending on tool compatibility and required torque specifications. For example, hex screws are often used in assembly-line settings for their efficiency.

The Role of Holes in Fastening

Holes serve as dedicated locations for screws, ensuring alignment and securing the assembly of various automotive components. Their characteristics are crucial for proper fastening:

- Diameter: The size of the hole must correlate with the screw diameter to ensure a tight fit. A hole that is too large can weaken the integrity of the connection, while one that is too small might not accommodate the screw.

- Threaded vs. Non-threaded Holes: Threaded holes allow the screw to grip firmly, whereas non-threaded holes might require the use of anchor inserts or rivets for securing components.

- Location: The precise location of holes is engineered to facilitate optimal weight distribution and mechanical advantage within the assembly, particularly in stress-bearing components like the engine block.

Types of Screws and Holes in Automotive Applications

There are several combinations of screws and holes designed for specific functions in vehicles:

1. Engine Assembly

In engine assembly, screws are used to secure components such as cylinder heads, oil pans, and intake manifolds. These screws have specific torque requirements that are crucial to preventing leaks or component failure due to vibrations.

2. Chassis Construction

In the vehicle’s chassis, screws and bolts often work in tandem with holes designed to bear the load of the vehicle’s weight and to absorb shocks from the road. Structural integrity is paramount, hence specific grades of screws (like grade 8) are employed.

3. Body Panels

Body panels often utilize screws for attachment to the frame. The holes in these cases may be designed for snap-fit or self-tapping screws, allowing for simple assembly with low labor costs.

Best Practices for Using Screws and Holes

To optimize the effectiveness of screws and holes, consider the following best practices:

- Correct Torque Specifications: Always adhere to manufacturer specifications for torque to prevent stripping threads or damaging components.

- Material Compatibility: Ensure screws are made from materials that are compatible with the components they are fastening, especially when dealing with dissimilar metals to avoid galvanic corrosion.

- Maintenance: Regularly inspect screw and hole integrity, particularly in high-vibration areas like the engine and suspension.

FAQs

What types of screws are used in automotive engineering?

Automotive engineering utilizes various screw types including hex screws, self-tapping screws, and machine screws, depending on the application and required fastening strength.

What is the significance of hole size in automotive applications?

The hole size must match the screw size to ensure a secure fit. A proper fit prevents component movement and potential structural failure, particularly in high-stress environments like engines.

How do screws and holes contribute to vehicle safety?

Screws and holes are critical for maintaining the integrity of vehicle components. Properly designed and executed fastening helps prevent accidents caused by component failure, thereby enhancing overall vehicle safety.

Can you replace a screw without affecting the surrounding components?

Replacing a screw may affect surrounding components if not done carefully. It’s essential to ensure that the replacement screw is of the same specification to prevent damaging the thread or altering alignment.

How do I choose the right screw for automotive applications?

Choosing the right screw involves considering the material type, thread specification, head style, and size. Consulting the vehicle’s documentation is crucial for selecting the correct fasteners for specific applications.