What is Dye Sublimation?

Dye sublimation is a digital printing technology that enables the transfer of dye onto various materials, particularly those with a polyester or polymer coating. This process uses heat and pressure to convert solid dye into a gas, which then permeates the material’s surface, allowing for vibrant, full-color designs that are long-lasting and resistant to fading. Unlike traditional printing methods, dye sublimation offers a unique advantage by embedding the dye within the substrate, producing high-quality images that maintain their sharpness and color intensity over time. Common applications include custom apparel, promotional items, and home décor, making dye sublimation a popular choice among businesses seeking to deliver personalized products with exceptional quality.

Understanding Dye Sublimation

Dye sublimation is a sophisticated printing technique that merges art with technology. Its unique process sets it apart from conventional printing methods, making it a preferred choice for many industries.

The Scientific Principle Behind Dye Sublimation

At its core, dye sublimation relies on the principles of thermodynamics. It begins with special sublimation inks that, when heated, transition directly from a solid state to a gaseous state without becoming liquid. This transformation occurs in a specialized printer designed for dye sublimation, typically equipped with a thermal print head. The essential elements of this process include:

- Dye Sublimation Inks: These inks are specially formulated to vaporize at a specific temperature, allowing them to bond with polyester surfaces.

- Heat Press: This device applies both heat and pressure to the printed transfer paper, facilitating the sublimation of the dye onto the chosen substrate.

- Polyester/Premade Materials: The dye sublimation process is most effective on materials with a polyester coating, as the dye binds directly to the fibers.

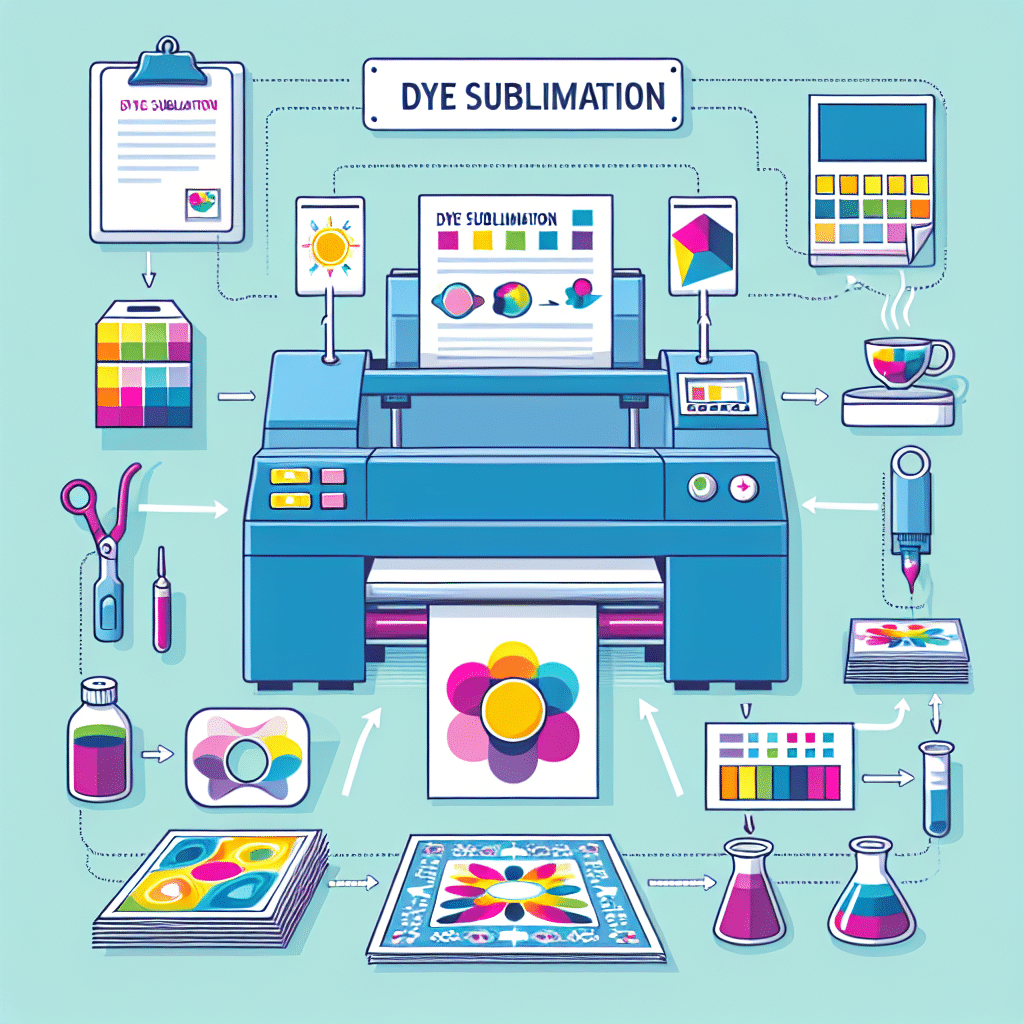

The Dye Sublimation Process

The dye sublimation process involves several key steps:

- Design Creation: Users create a digital design using graphic design software, optimizing it for the intended substrate.

- Printing: The design is printed onto transfer paper using dye sublimation ink.

- Heat Transfer: The transfer paper is placed on the substrate and subjected to heat and pressure using a heat press, causing the dye to sublimate and bond with the substrate.

- Cooling: Once the heat is removed, the substrates cool down, locking in the vibrant colors and designs.

Benefits of Dye Sublimation

Dye sublimation offers numerous advantages over traditional printing methods, making it the go-to choice for various applications:

1. High-Quality Prints

The dye sublimation method produces stunning, photo-realistic images with superior color vibrancy and depth, making it ideal for a wide range of products from sportswear to promotional materials.

2. Durability

Because the dye permeates the fabric, the prints are resistant to fading, cracking, and peeling – providing durable and long-lasting results even after multiple washes.

3. Customization

Dye sublimation allows for extensive customization. Businesses can create one-of-a-kind products tailored to their clients’ specifications, such as custom uniforms, signage, and home décor.

4. Eco-Friendly Options

With increasing emphasis on sustainability, many dye sublimation inks are water-based and non-toxic, making the process more environmentally friendly compared to other printing methods.

Applications of Dye Sublimation

Dye sublimation is versatile and has found applications across various industries:

1. Apparel

The fashion industry benefits significantly from dye sublimation, which is prevalent in creating custom sports jerseys, T-shirts, and activewear. The technique allows for all-over printing without losing fabric quality.

2. Home Décor

Dye sublimation can be applied to home goods such as cushions, curtains, and framed prints, offering homeowners customization options for their living spaces.

3. Promotional Products

Businesses utilize dye sublimation to create branded promotional items, including mugs, banners, and phone cases, enhancing brand visibility through personalized merchandise.

4. Signage and Displays

Many companies use dye sublimation for creating lightweight, durable signage that retains vibrant colors over time, suitable for both indoor and outdoor use.

Limitations of Dye Sublimation

Despite its many advantages, dye sublimation does have some limitations:

1. Material Restrictions

Dye sublimation is primarily effective only on polyester or polyester-coated materials. This constraint can limit its applicability for certain products.

2. Initial Costs

The setup costs for dye sublimation printing equipment and materials can be high, making it less accessible for smaller businesses. However, the investment tends to yield long-term benefits through high-quality outputs.

3. Time-Consuming Process

The process may take longer compared to other printing methods, particularly when working with multiple layers or complex designs.

In Conclusion

Dye sublimation stands out as a proficient and robust printing technique, offering an array of benefits ideal for businesses and consumers alike. By understanding both its advantages and limitations, you can make informed choices when considering dye sublimation for your projects. The process’s potential to enable precise, vibrant designs that are durable and customizable has cemented its place in numerous industries, from fashion to promotional products.

FAQ Section

What materials can be used with dye sublimation?

Dye sublimation works best with polyester fabrics or materials coated with a polymer layer. Some common substrates include T-shirts, mugs, banners, and promotional items.

How long does the dye sublimation process take?

The time required varies depending on the number of items and complexity of the designs. Typically, a single transfer can take anywhere from a few minutes to over an hour to complete, especially with multiple prints involved.

Is dye sublimation eco-friendly?

Yes, water-based sublimation inks are generally considered more eco-friendly compared to solvent-based inks, given their non-toxic and low VOC (volatile organic compound) content.

Can dye sublimation be used for dark fabrics?

While traditional dye sublimation printing is best suited for light-colored fabrics, techniques have been developed, such as using transfer paper with specific additives that allow for sublimation on darker textiles, albeit with varying results.