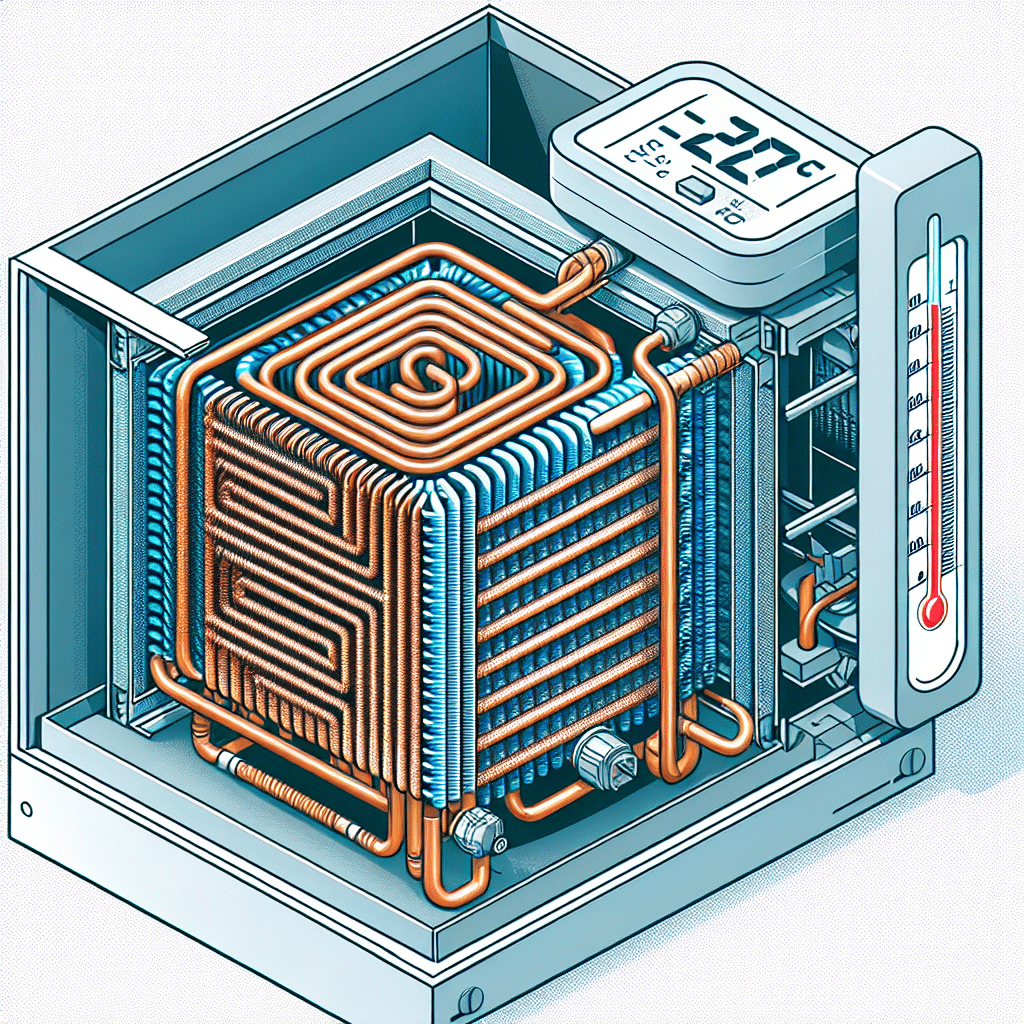

The evaporator coil temperature in a box freezer is crucial for maintaining the optimal performance of the appliance, ensuring efficient cooling and preserving the longevity of stored items. Generally, the evaporator coil should operate within a temperature range of 0°F to 20°F (-18°C to -6°C). This temperature is necessary to achieve and maintain the desired internal freezing temperature, which typically hovers around 0°F (-18°C) for long-term freezing applications. A coil temperature that is too high can lead to insufficient cooling, risking spoilage of frozen goods, while a temperature that is too low can cause frost accumulation, which reduces efficiency and can lead to equipment failure. Understanding how to monitor and manage the evaporator coil temperature is essential for both commercial users and residential consumers to ensure the effective use of their box freezer.

Understanding Box Freezers and Their Components

Box freezers, commonly utilized in both commercial settings, such as restaurants and supermarkets, and residential spaces, offer a reliable solution for freezing a variety of food items. The fundamental principle behind a box freezer involves a refrigeration cycle, where heat is removed from the interior space, thus cooling the stored contents.

The Role of the Evaporator Coil

The evaporator coil plays a pivotal role in this refrigeration cycle. When refrigerant passes through the evaporator coil, it absorbs heat from the surrounding space. This process converts the refrigerant from liquid to gas, effectively extracting heat and lowering the temperature within the freezer. A well-maintained evaporator coil ensures efficient heat exchange, optimizing the performance of the freezer.

Optimal Evaporator Coil Temperature Range

Maintaining an optimal evaporator coil temperature is critical for efficient operation. As noted earlier, a temperature range of 0°F to 20°F (-18°C to -6°C) is typically recommended. Several factors can influence this temperature:

- Ambient Temperature: The external environment affects how efficiently the evaporator coil can extract heat. Higher ambient temperatures can lead to higher coil temperatures.

- Load Conditions: The amount and type of items stored inside the freezer can impact the evaporator coil temperature. A fully loaded freezer retains cold better than one that is not adequately stocked.

- Defrost Cycle: The frequency and efficiency of the defrost cycle can also alter evaporator coil temperatures. Ideally, the freezer should defrost regularly to prevent frost build-up, which can impair heat exchange.

How to Monitor Evaporator Coil Temperature

Monitoring the evaporator coil temperature is essential for maintaining optimal freezing conditions. Here are some effective methods:

1. Temperature Sensors

Most modern box freezers come equipped with built-in temperature sensors that continuously monitor the evaporator coil’s temperature. Regularly checking the display panel can help you ensure the temperature is within the desired range.

2. Thermocouples

If your freezer lacks a built-in monitor, you can use an external thermocouple. This device can be inserted into the evaporator coil area to accurately gauge the temperature.

3. Manual Thermometers

A simple solution involves placing a thermometer in the freezer compartment to observe temperature fluctuations over time. This method, while not as precise, can provide a general idea of freezer performance.

Common Issues Affecting Evaporator Coil Temperature

Several issues can lead to improper evaporator coil temperatures, affecting overall freezer performance and food preservation.

1. Frost Build-Up

Excessive frost accumulation on the evaporator coil acts as insulation, hindering heat exchange. This may lead to higher coil temperatures, causing the freezer to work harder and consume more energy.

2. Refrigerant Leaks

Low refrigerant levels due to leaks can reduce the efficiency of the cooling process. This may result in higher evaporator coil temperatures and ultimately impact the internal temperature of stored items.

3. Dirty Coils

Dust and debris can accumulate on the evaporator coils, insulating them and impeding heat absorption. Regular cleaning is essential to maintain optimal coil performance.

Maintaining Ideal Evaporator Coil Temperature

To ensure that the evaporator coil temperature remains within the recommended range, several maintenance steps can be adopted:

1. Routine Cleaning

Physically cleaning the evaporator coil of dust, dirt, and frost at least twice a year will help ensure efficient operation, keeping the coils clean allows for effective heat transfer.

2. Regular Inspections

Conducting inspections for wear and tear, particularly for refrigerant leaks and mechanical issues, can help avert significant problems in the long run.

3. Professional Servicing

Consider hiring a qualified technician to perform routine maintenance, including checking refrigerant levels and thermostat calibration. This will help ensure that all components are functioning optimally.

FAQs

What happens if the evaporator coil temperature is too low?

If the evaporator coil temperature drops below the recommended range, frost and ice may accumulate, potentially causing the evaporator to freeze over. This can lead to inadequate cooling and reduced storage efficiency.

How can I tell if my evaporator coil is working properly?

Signs of proper functioning evaporator coils include consistent internal temperatures within the freezer, no excessive frost buildup, and normal energy consumption. If your box freezer is running unusually cold or warm, it may indicate a problem.

What should I do if I think my evaporator coil is faulty?

If you suspect an issue with your evaporator coil, consult with a qualified refrigeration technician for diagnosis and repair. Attempting to fix refrigerant issues or mechanical problems without proper expertise can lead to further complications.

Conclusion

Understanding the evaporator coil temperature in your box freezer is essential for ensuring optimal performance and longevity. By monitoring this temperature and adopting proper maintenance practices, you can enhance energy efficiency and preserve the quality of your frozen goods. Regular inspections and timely professional assistance when issues arise will significantly contribute to the optimal functioning of your cooling equipment.