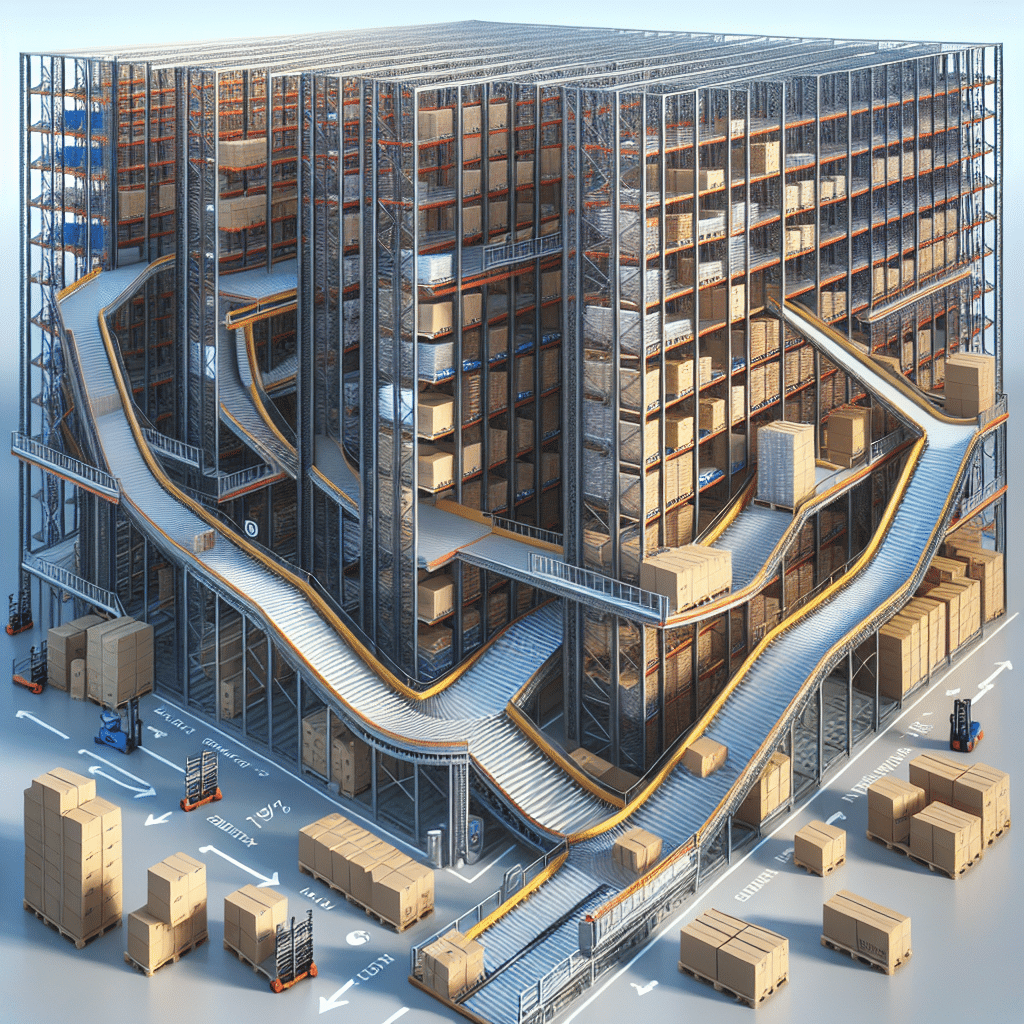

Gravity flow racking is a type of storage system that utilizes gravity to facilitate the efficient movement of products within a warehouse or storage facility. This method involves angled shelving that allows products, typically housed on roller tracks or skids, to flow from the higher to the lower positions. Gravity flow racking is especially beneficial in high-density storage environments, as it maximizes storage space while ensuring easy access to inventory. By allowing items to be stored in a “first-in, first-out” (FIFO) manner, businesses can reduce spoilage and streamline picking processes. This racking system is ideal for handling a variety of products, including perishables and bulk items, making it a valuable asset in logistics and supply chain management.

Understanding Gravity Flow Racking

Gravity flow racking is a sophisticated storage solution designed to optimize space, enhance productivity, and improve inventory management. In contrast to traditional racking systems, where items are placed on shelves manually, gravity flow racking relies on gravity and a sloped design to allow items to roll toward the picking area. This methodology is particularly advantageous for businesses seeking efficiency in their warehousing operations.

Key Components of Gravity Flow Racking

This racking system consists of several essential components:

- Tracks: These are typically made of rollers or wheels designed to allow products to glide smoothly down the incline.

- Framework: The structure is made of sturdy materials, such as steel, ensuring durability and load-bearing capacity.

- Inclined Shelves: Designed at an angle, these shelves facilitate the movement of products by leveraging the force of gravity.

- End Stops: These safety features prevent products from rolling off the end of the rack.

How Gravity Flow Racking Works

The operation of gravity flow racking is straightforward:

- Loading: Products are loaded onto the upper side of the racking system, typically in a FIFO sequence.

- Gravity Assistance: As items are pushed to the back, gravity pulls them forward, so they roll down the incline and into the picking area.

- Picking: Warehouse staff can easily access and remove items from the front, ensuring a seamless picking process.

Benefits of Gravity Flow Racking

This storage solution offers numerous advantages:

1. Space Optimization

One of the primary benefits of gravity flow racking is its ability to maximize vertical storage space. By consolidating products in a smaller area while still allowing for efficient access, businesses can reduce the footprint of their storage operations.

2. Improved Inventory Management

The FIFO approach inherent in gravity flow racking helps prevent product spoilage and ensures that older stock gets picked first. This is particularly crucial in industries dealing with perishable goods or items with expiration dates.

3. Enhanced Picking Speed

By reducing the need for workers to navigate aisles to find products, gravity flow racking can significantly speed up order fulfillment times. Workers can quickly access items at the front of the system, leading to improved labor efficiency.

4. Reduced Labor Costs

The design of gravity flow racking minimizes the steps required for picking and replenishing stock. This operational efficiency can translate into lower labor costs as fewer workers are needed for warehouse operations.

Applications of Gravity Flow Racking

Gravity flow racking is versatile and suitable for various industries, including:

- Food and Beverage: Ideal for managing perishables that require fast turnover rates.

- Pharmaceuticals: Essential for maintaining stock integrity and adherence to FIFO protocols.

- Retail: Efficiently handles seasonal inventory and promotes manageable restocking strategies.

- Automotive: Useful for organizing parts in a compact manner while ensuring quick access.

Potential Drawbacks of Gravity Flow Racking

While gravity flow racking presents numerous benefits, it is essential to consider potential drawbacks:

1. Initial Investment

The upfront cost of installing a gravity flow racking system can be significantly higher than traditional shelving solutions. However, the return on investment often justifies the expense through increased efficiency.

2. Complexity of Design

Designing an effective gravity flow racking system requires careful planning and expertise. Facilities must assess their specific needs, weight limits, and storage types to avoid complications.

3. Maintenance Requirements

Regular maintenance is essential to ensure the smooth operation of the rollers and tracks. Neglecting maintenance can result in decreased efficiency and potential safety hazards.

Implementing Gravity Flow Racking in Your Facility

If you are considering gravity flow racking for your business, follow these steps for successful implementation:

1. Assess Your Needs

Evaluate the nature of your inventory, the required turnover rates, and the available space to determine if gravity flow racking aligns with your operational goals.

2. Consult Experts

Collaborate with warehouse design specialists to create an efficient layout that optimizes your storage space while ensuring safety and functionality.

3. Choose the Right Supplier

Select a reputable supplier with experience in gravity flow racking systems. Evaluate their previous projects and references to ensure reliability.

4. Implement Training Programs

Train staff on the operation of the new system to minimize errors and maximize efficiency from day one.

Frequently Asked Questions (FAQ)

What is the difference between gravity flow racking and traditional racking systems?

Traditional racking systems rely on manual picking, while gravity flow racking uses gravity to facilitate the movement of goods, enhancing efficiency and streamlining processes.

Is gravity flow racking suitable for all types of products?

Gravity flow racking is ideal for fast-moving items and products with expiration dates. However, businesses should evaluate the design and weight limits for specific applications.

How does gravity flow racking improve safety in warehouses?

By minimizing congestion and reducing the need for excessive manual handling, gravity flow racking can lead to safer working conditions and a reduction in workplace injuries.

What factors should be considered when designing a gravity flow racking system?

Key considerations include the type of products, weight limits, warehouse layout, and accessibility for picking and replenishing stock.

Conclusion

In summary, gravity flow racking presents a dynamic solution for modern warehousing and inventory management. By capitalizing on space efficiency, improved inventory turnover, and faster picking processes, organizations can enhance operational efficiency while minimizing waste. As logistics evolves, gravity flow racking remains a staple in optimizing storage solutions, proving particularly beneficial for industries dealing with perishable goods and high-demand items. Assessing your unique requirements and collaborating with experts in the field will ensure you harness the full potential of this innovative storage system.