What is an I/O Board on a Pool Pump?

An I/O board, which stands for Input/Output board, is a crucial component of a pool pump’s control system. Within the context of pool pumps, the I/O board functions to manage various electrical signals that control the operation of the pump itself. This includes controlling the motor speed, initiating the pump’s startup, and regulating communication between the pump and other components of the pool system. Essentially, the I/O board acts as a bridge between the user interface, like your control panel, and the mechanical aspects of the pump, ensuring smooth operation and efficiency. Understanding its functionality can help pool owners troubleshoot issues related to pump performance and maintenance.

Understanding the Role of the I/O Board in Pool Pumps

The I/O board plays a vital role in the functionality and efficiency of a pool pump. Its main responsibilities include processing input signals from various sensors, controls, and user interfaces, and translating these into output signals that direct the pump’s motor functions.

Key Functions of the I/O Board

1. Motor Control

The I/O board regulates the motor’s operation, including its speed settings. By varying the motor speed, the board can optimize energy consumption according to the pool’s filtration needs, which can lead to significant savings on operational costs.

2. Communication Management

This board enables communication between the pool pump and other electronic components, such as timers, thermostats, and remote controls. This interconnectivity allows users to program their pump for specific schedules or operational modes.

3. Error Detection and Troubleshooting

Advanced I/O boards often include diagnostic capabilities that can alert pool owners to any operational issues or errors. These alerts can help prevent further complications by prompting timely maintenance or repairs.

4. Safety Features

The I/O board integrates safety features that protect the pool pump from electrical faults. These safeguards ensure that the pump operates within safe parameters, reducing the risk of overheating or damage.

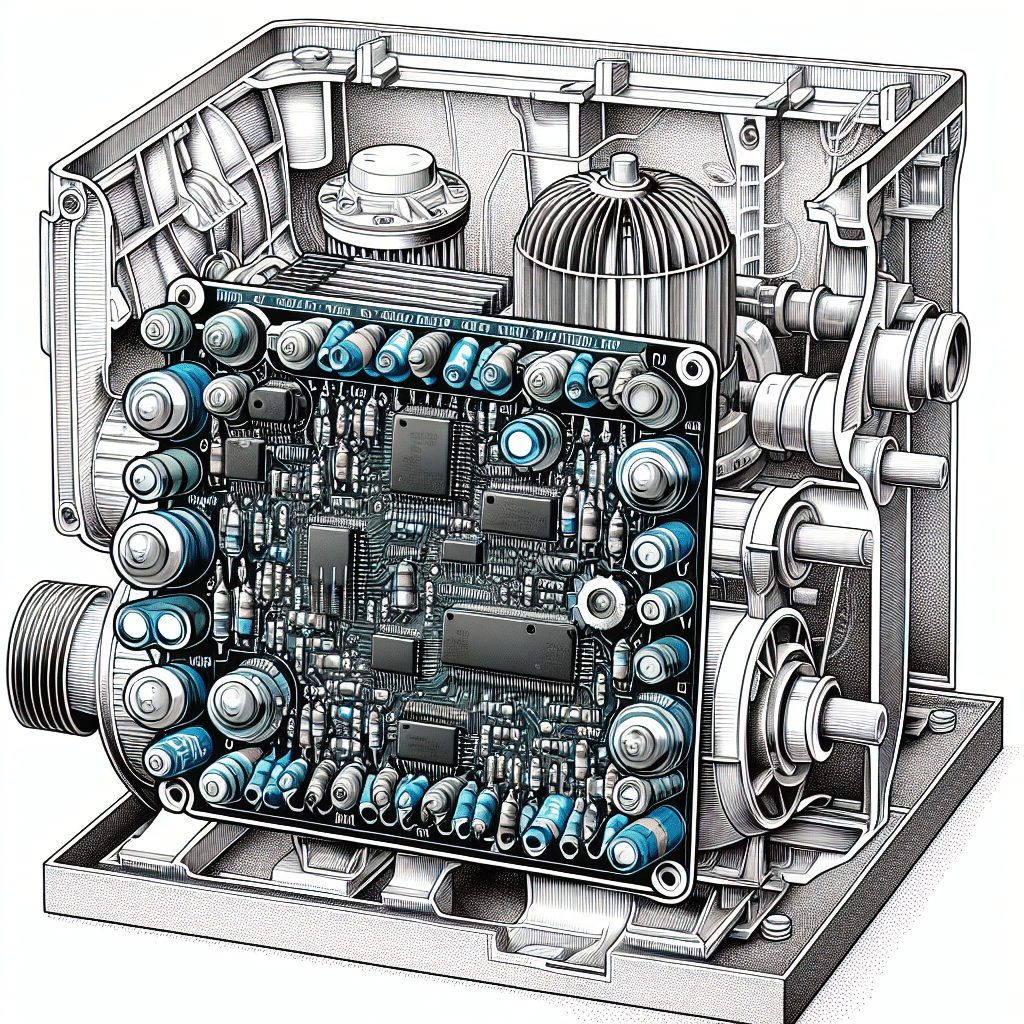

Component Breakdown of the I/O Board

To understand the I/O board better, it’s important to know the various components that comprise it.

1. Microcontroller

This is the brain of the I/O board. The microcontroller processes input data and sends commands to the pump motor, making decisions based on predefined parameters or user settings.

2. Relay Switches

Relay switches are used to manage the power supply to the pump motor. They act as automated switches that are activated by the microcontroller to turn the motor on or off as required.

3. Input Terminals

These terminals connect various sensors and user controls to the I/O board, allowing for data input on operational parameters and settings.

4. Output Terminals

Output terminals facilitate communication from the I/O board to other connected devices, delivering signals that control the pump’s motor.

5. Safety Circuitry

This component monitors the operational status of the pump and intervenes in case of any electrical malfunction, acting as a protective measure to prevent damage.

Common Issues and Troubleshooting for I/O Boards

Because the I/O board is central to the functioning of the pool pump, any malfunction can disrupt overall performance. Here are some frequent issues and troubleshooting approaches:

1. Pump Not Starting

If your pump fails to start, the I/O board may be at fault. Check the input connections and ensure the control panel is functioning. If necessary, test the relays for proper operation.

2. Inconsistent Performance

Erratic motor speed can often be traced back to a faulty microcontroller or relay. Performing a diagnostic check using the error codes displayed (if available) can identify the specific components needing attention.

3. Overheating

Overheating issues can arise if the I/O board fails to regulate power inputs correctly. Inspect all electrical connections and ensure the safety circuits are functioning as intended.

Frequently Asked Questions (FAQ)

What signs indicate a failing I/O board in a pool pump?

Common signs include erratic behavior in the pump’s operation, failure to start, unusual sounds, and error messages displayed on the control panel. If you notice these signs, investigating the I/O board is essential.

Can I replace the I/O board myself?

While replacing an I/O board can be a straightforward task for someone with basic electrical knowledge and experience, it is advisable to consult with a professional if you are unsure. Incorrect installation can lead to further damage or safety hazards.

How can I avoid issues with my pool pump’s I/O board?

Regular maintenance, including checking electrical connections and keeping the pump clean, can help prevent issues. Additionally, ensuring proper voltage levels can enhance the longevity of the I/O board.

Are all I/O boards compatible with any pool pump?

No, I/O boards are typically designed for specific models or brands of pool pumps. When replacing, it’s crucial to consult the manufacturer’s specifications to ensure compatibility.

Conclusion

The I/O board is a critical component in the operation of your pool pump, coordinating signals and commands that ensure efficient performance. Understanding its functions, components, and potential issues can empower you to maintain your pool system more effectively and make informed decisions regarding repairs and replacements.