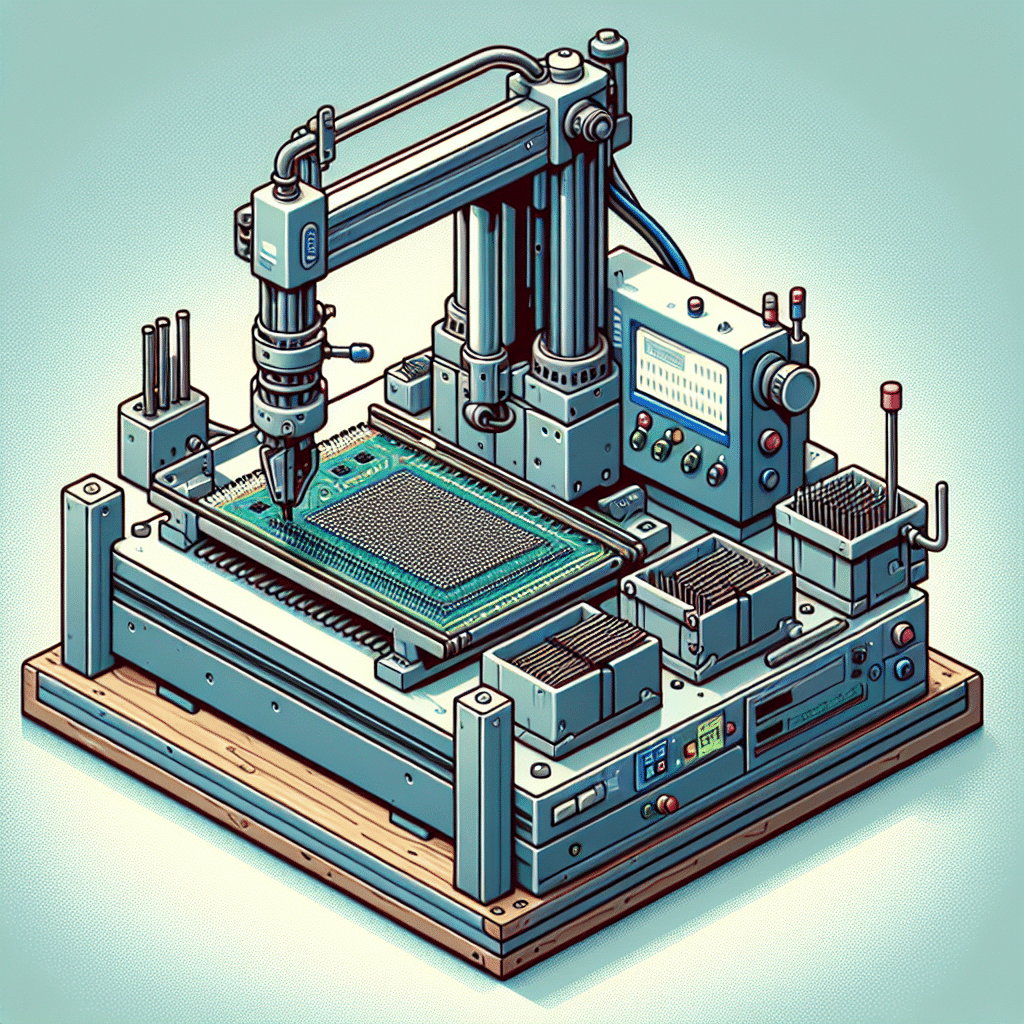

What is a PCB Pinner? A PCB pinner, or PCB pinning machine, is a specialized device employed in the assembly and manufacturing of printed circuit boards (PCBs). Its primary function is to securely hold components in place on a PCB during the soldering process, ensuring precision and accuracy while minimizing defects. In today’s advanced electronics fabrication, the PCB pinner plays a crucial role in enabling the detection of component misalignments and enhancing the overall efficiency of production lines. By using a PCB pinner, manufacturers can significantly reduce manual labor, achieve higher throughput, and maintain stringent quality control in their assembly processes. This device is essential for both small-scale workshops and large manufacturing facilities in the United States and around the world, as it provides consistent performance and reliability.

Understanding PCB Pinning: A Deeper Dive

The journey of a PCB from concept to a fully functional electronic device involves multiple stages, one of which is the assembly phase where components are soldered onto the PCB. This is where a PCB pinner comes into play. Here, we will explore its mechanics, benefits, and applications in greater detail.

What is a Printed Circuit Board (PCB)?

Before diving deep into the role of a PCB pinner, it’s essential to understand what a PCB is. A Printed Circuit Board (PCB) is a flat board that electrically connects and supports electronic components. The assembly process involves placing components onto the board and soldering them in place to establish electrical connections.

The Role of PCB Pinning Machines

A PCB pinner holds electronic components (such as resistors, capacitors, and ICs) in position during the soldering process, ensuring accuracy in alignment. The process typically includes:

- Component Placement: Components are fed into the machine, which positions them in designated spots on the PCB.

- Pinning: The PCB pinner aligns the components and secures them with pins or other mechanisms to prevent movement.

- Soldering: Once everything is in place, the PCB undergoes soldering, either through wave soldering, reflow soldering, or manual methods.

How Does a PCB Pinner Work?

PCB pinning machines utilize an array of mechanical arms, clamps, or pins that engage with the components and hold them firmly against the PCB surface. The typical workflow is as follows:

- Loading: The PCB pinner is loaded with the PCB and required components.

- Positioning: Once the components are loaded, the machine positions them according to the generated assembly program based on the PCB design.

- Pinning Mechanism: Pins or clamps then secure each component to the PCB as the machine checks their positioning to ensure accuracy.

- Release and Transfer: After the components are securely pinned, the PCB is then transferred to the soldering station.

Benefits of Using a PCB Pinner

There are several advantages of utilizing a PCB pinner in electronic assembly:

- Increased Precision: Automated pinning ensures that components are accurately aligned, significantly reducing the risk of misplacement.

- Efficiency: Using a PCB pinner streamlines the assembly process, enabling faster production times and higher output rates.

- Quality Control: The use of this technology minimizes defects and enhances the overall quality of assembled PCBs.

- Cost-Effectiveness: By reducing manual labor and errors, companies can save on production costs and enhance profitability.

Key Applications of PCB Pinners

PCB pinning machines find widespread use in various sectors:

- Consumer Electronics: Used in the assembly of devices like smartphones, tablets, and computers.

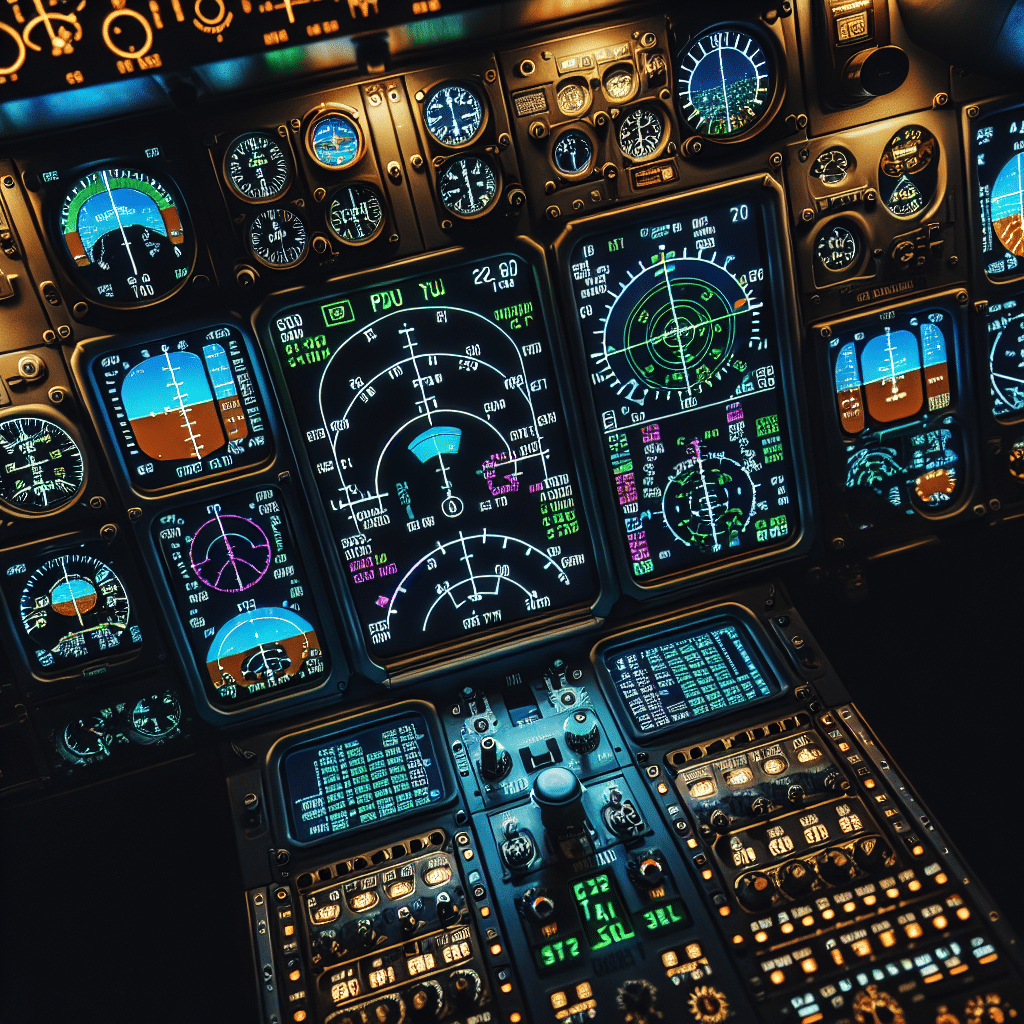

- Automotive Industry: Key in assembling control units and sensors in vehicles.

- Medical Devices: Critical for maintaining precision and safety standards in medical equipment.

- Industrial Equipment: Helps in the assembly of control panels and monitoring systems.

Types of PCB Pinners

There are several types of PCB pinning machines available, each tailored for different production needs:

- Manual PCB Pinners: Often used in smaller operations or workshops, these machines require greater operator involvement.

- Automatic PCB Pinners: High-speed machines capable of handling large volumes and incorporating advanced programming for maximum efficiency.

- Programmable PCB Pinners: These machines can be set to specific configurations depending on the requirements of different PCB layouts.

Challenges and Counterarguments

While PCB pinners offer numerous benefits, one must also consider certain challenges:

- Initial Investment: High-quality PCB pinners can be a significant capital investment, posing a barrier for smaller companies.

- Maintenance: Like any machinery, PCB pinners require regular maintenance to ensure reliability and avoid production downtime.

- Complexity: The operational complexity can necessitate skilled personnel for programming and machine operation.

However, the long-term returns on investment, in terms of labor cost savings and increased production efficiency, often outweigh these challenges. Many businesses find that the enhanced quality and reduced defect rates justify the initial costs.

Future Trends in PCB Pinning Technology

The PCB industry is continuously evolving, and this includes advancements in pinning technology. Some anticipated trends include:

- Integration of AI and Machine Learning: Future machines may utilize AI for improved accuracy in component placement and diagnostics.

- Collaborative Robots (Cobots): As automation becomes more prevalent, cobots may work alongside human operatives to enhance efficiency.

- Sustainability: The push for eco-friendly practices may lead to the development of sustainable PCB pinning solutions.

FAQ Section

What materials are used in PCB pinning machines?

PCB pinning machines typically include durable components made of metal alloys for mechanical parts and high-quality plastics for casing to withstand operational wear and tear.

Can PCB pinning machines handle different types of components?

Yes, most PCB pinning machines are versatile enough to manage a range of components, including through-hole and surface mount devices.

How does a PCB pinner improve production efficiency?

A PCB pinner enhances production efficiency by minimizing the time spent on manually aligning and securing components, enabling quicker transitions between assembly stages.

What should I consider when purchasing a PCB pinner?

When purchasing a PCB pinner, consider factors such as operational speed, component compatibility, ease of use, cost, and maintenance requirements.

Conclusion

In summary, a PCB pinner is an integral part of modern electronics manufacturing that ensures the accurate and efficient assembly of printed circuit boards. As the technology continues to advance, the potential of PCB pinning machines will only expand, leading to better-quality electronic devices and streamlined production processes. For companies in the US and worldwide, investing in high-quality PCB pinning machinery can significantly enhance overall operational effectiveness and product reliability.