Introduction

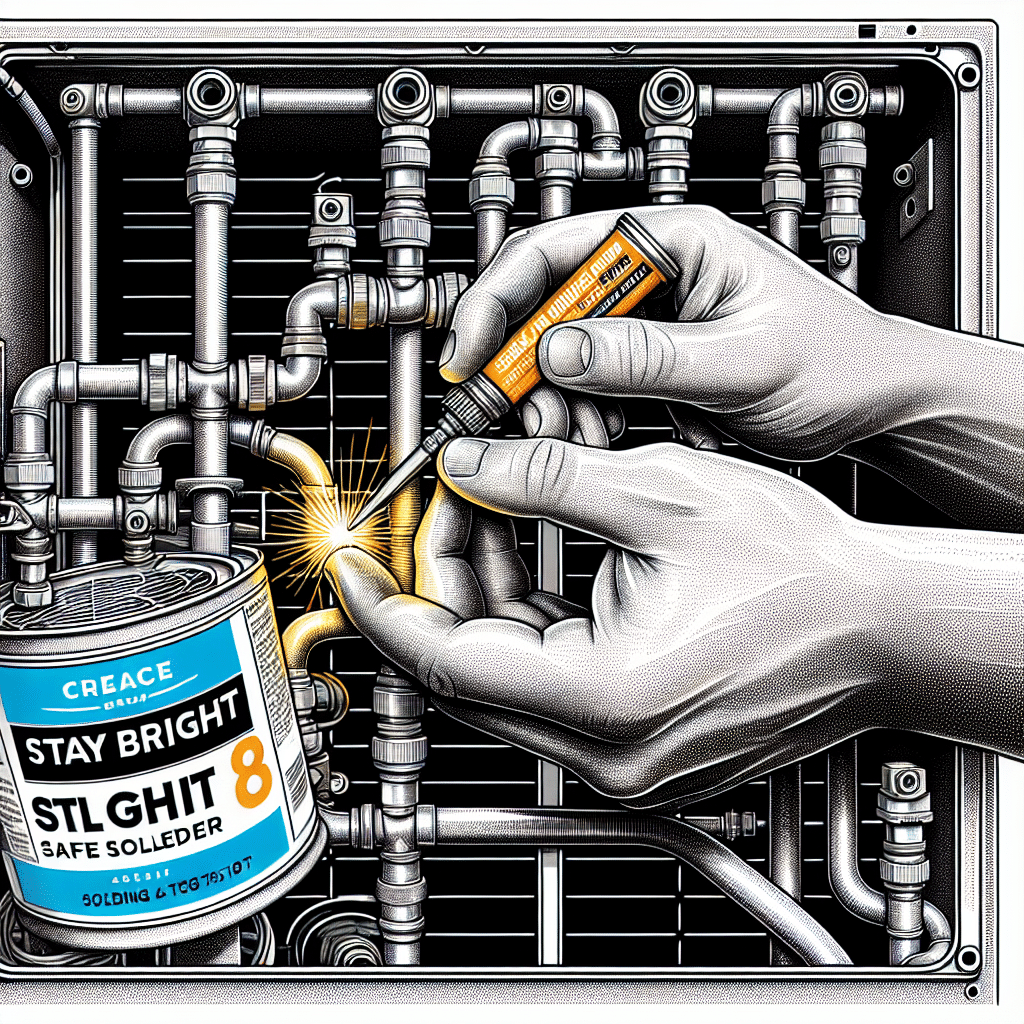

Stay Brite 8 is a widely recognized silver solder used in HVAC (Heating, Ventilation, and Air Conditioning) applications, particularly for joining copper components in systems that utilize R410A refrigerant. Known for its excellent flow characteristics and strength, Stay Brite 8 is suitable for both residential and commercial HVAC systems. It offers a reliable solution when working with R410A due to its ability to create strong, leak-resistant joints that withstand the high pressures and temperatures associated with this type of refrigerant. The product is notably easy to work with, providing consistent results that HVAC technicians trust. Its formulation, combined with phosphorous, ensures that it is free from lead, making it safe and compliant with environmental regulations. Thus, for any HVAC technician or enthusiast, understanding the compatibility and benefits of Stay Brite 8 when used with R410A refrigerant is essential.

Understanding R410A Refrigerant

R410A is a hydrofluorocarbon (HFC) refrigerant commonly used in air conditioning systems due to its efficiency and lower environmental impact compared to older refrigerants like R22. With an ozone depletion potential of zero, R410A is the preferred refrigerant for many modern HVAC applications. Its properties enable it to operate at higher pressures, providing better cooling performance and energy efficiency.

Chemical Properties of R410A

R410A is a blend of R32 and R125 in a ratio of 50/50. It has properties that make it effective for heat transfer and energy efficiency, including:

- Higher pressure ratings: R410A systems typically operate at about 50% higher pressure than R22 systems.

- Effective thermal properties: Offers better cooling capacity with lower energy consumption, resulting in reduced operational costs.

Why Stay Brite 8 is Essential for R410A Applications

When working with R410A, the soldering materials used must be selected carefully to ensure compatibility and performance. Stay Brite 8 is particularly beneficial in this regard.

Features and Benefits of Stay Brite 8

Stay Brite 8 offers several features that make it suitable for HVAC applications involving R410A refrigerant:

1. Strong Bonding

Stay Brite 8 creates robust joints that can withstand the high pressures characteristic of R410A systems. This strength helps reduce the chances of leaks, which is critical for optimal system performance and safety.

2. Excellent Flow Characteristics

Its ability to flow well into joints facilitates superior capillary action. This property ensures complete penetration into the joint, leading to a more effective seal.

3. No Flux Required

Unlike many other solders, Stay Brite 8 can be used without flux, simplifying the soldering process and improving the overall efficiency of HVAC installation or repair tasks. This leads to cleaner joints and minimizes the risk of contamination.

4. Lead-Free Composition

The lead-free formulation of Stay Brite 8 not only complies with health and environmental regulations but also makes it a safer option for technicians and end-users.

5. Versatility

Aside from refrigeration systems using R410A, Stay Brite 8 can also be used effectively with various metals, primarily in sectors like plumbing and automotive.

Application Techniques for Stay Brite 8 with R410A

Using Stay Brite 8 requires attention to detail and adherence to best practices to ensure optimal results when soldering in a system utilizing R410A. Here are some recommended techniques:

1. Surface Preparation

Ensure that the surfaces to be joined are clean, free from oxidation, and adequately prepared by sanding or filing. This step is crucial for achieving good adhesion.

2. Proper Heating

Use a suitable torch to heat the materials evenly before introducing the solder. The recommended soldering temperature is around 400°F to 600°F (204°C to 316°C). Avoid overheating, which can damage the components.

3. Applying Stay Brite 8

Once the joint reaches the appropriate temperature, introduce Stay Brite 8 by melting it into the joint. Allow the solder to flow and fill gaps, ensuring a tight joint.

4. Cleaning After Soldering

After allowing the joint to cool down, remove any residual solder or flux for clean and professional results. This step reduces the risk of corrosion and enhances system reliability.

Common FAQs about Stay Brite 8 and R410A Refrigerant

1. Is Stay Brite 8 compatible with all refrigerants?

While Stay Brite 8 is suitable for many refrigerants, including R410A, it’s important to verify compatibility with other specific refrigerants before use, especially if they have different chemical properties.

2. Can Stay Brite 8 be used on older systems using R22?

Yes, Stay Brite 8 can be used on R22 systems. However, ensure that the materials and joint types are suitable for the higher pressures of R410A if retrofitting or repairing existing systems.

3. Does Stay Brite 8 require a flux when soldering?

No, Stay Brite 8 does not require a flux, which simplifies the soldering process. However, cleanliness of the metal surfaces is essential for achieving good solder joints.

4. How does Stay Brite 8 compare to other soldering materials?

Stay Brite 8 is superior to many traditional solders due to its high strength, flow characteristics, and lead-free composition. It is specifically designed for high-pressure applications found in modern HVAC systems.

Conclusion

In summary, Stay Brite 8 is an excellent choice for HVAC professionals working with R410A refrigerant. Its strong bonding capabilities, excellent flow characteristics, and safe formulation make it a trusted option for joining copper components in HVAC systems. By adhering to proper application techniques, technicians can ensure leak-free, reliable, and efficient operation of R410A systems, enhancing performance and longevity.