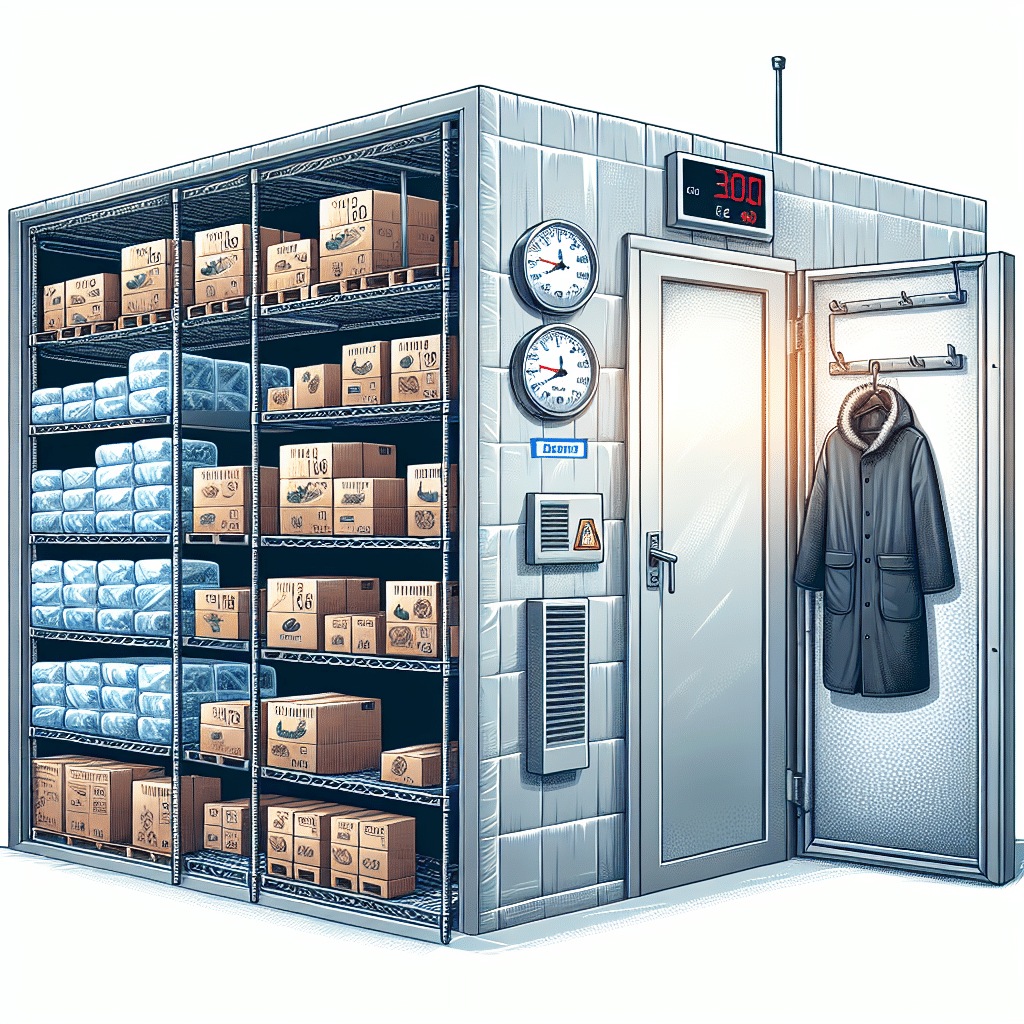

What is the Cold Room Called? The cold room is commonly referred to as a refrigeration room or a cold storage room. It is a specially designed space that maintains low temperatures for the preservation of perishable items, including food, pharmaceuticals, and other temperature-sensitive products. Often found in warehouses, grocery stores, and food processing facilities, refrigeration rooms uphold temperatures significantly below ambient levels to prevent spoilage and maintain product quality. Additionally, some businesses may use terms like chill room, freezer room, or cold facility, depending on the specific temperature requirements of the items stored within. Overall, these controlled environments are essential for industries that rely on safe food storage and distribution, ensuring compliance with health standards and extending shelf life.

Understanding Cold Rooms

Cold rooms, also known as refrigeration rooms or cold storage facilities, play a crucial role in various industries, from food and beverage to pharmaceuticals and logistics. Their main function is to provide a controlled temperature environment to preserve perishable goods and sensitive materials effectively. With their ability to maintain low temperatures, these facilities prevent spoilage, bacterial growth, and degradation of quality in stored products.

Types of Cold Rooms

Cold rooms can be categorized based on their design, temperature requirements, and purpose. Understanding the different types can help businesses choose the right cold storage solution for their specific needs.

1. Refrigeration Rooms

Refrigeration rooms maintain a temperature range typically between 32°F and 50°F (0°C to 10°C). These rooms are ideal for storing fresh produce, dairy products, and other items that require cool temperatures but not freezing conditions.

2. Freezer Rooms

Freezer rooms operate at temperatures below 0°F (-18°C). This type of cold storage is necessary for items such as frozen fruits, vegetables, meats, and ice cream. The equipment in freezer rooms often includes blast freezers and walk-in freezers tailored for bulk storage.

3. Chill Rooms

Chill rooms are designed to store items that require slightly cooler conditions than regular refrigeration. These rooms maintain temperatures between 36°F and 45°F (2°C to 7°C) and are typically used for items that do not require complete freezing.

4. Controlled Atmosphere Rooms

Controlled atmosphere rooms go beyond simple refrigeration by regulating not only temperature but also humidity and gas levels (such as oxygen and carbon dioxide). These rooms are prevalent in the storage of fruits and vegetables, as they can extend the shelf life of produce significantly.

Key Components of Cold Rooms

To function effectively, cold rooms are equipped with various components and technologies that help maintain the desired conditions.

1. Insulation

High-quality insulation materials are essential for preventing heat transfer and ensuring minimal energy loss. Insulated panels, often made of polyurethane or polystyrene, are standard in constructing cold rooms.

2. Refrigeration Systems

The refrigeration system is the heart of a cold room. It typically includes compressors, condensers, expansion valves, and evaporators that work together to cool the air inside the space. Regular maintenance and monitoring of these systems are vital to ensure long-term functionality.

3. Monitoring Systems

To maintain optimal conditions, cold rooms often employ monitoring systems that track temperature and humidity levels. Modern systems may use IoT technology to send alerts and data to operators, allowing for real-time adjustments and preventive actions.

4. Racking Systems

Proper racking systems maximize space utilization and enable efficient organization of stored items. Different types of racking systems, such as pallet racks, shelving, and stackable bins, facilitate easy access and inventory management.

Applications of Cold Rooms

Cold rooms find applications across various sectors. Below are some of the primary industries that rely on cold storage solutions:

1. Food Industry

The food industry is the largest user of cold storage facilities. They store perishable goods like fruits, vegetables, meats, dairy, and seafood at safe temperatures to prevent spoilage and ensure freshness. Restaurants, supermarkets, and food manufacturers benefit significantly from efficient cold storage solutions.

2. Pharmaceutical Industry

In pharmaceuticals, cold storage is critical for preserving vaccines, medications, and certain laboratory supplies. Many pharmaceutical products require strict temperature controls to maintain their efficacy. This also includes the storage of blood products, which must remain at specific temperatures.

3. Chemical and Laboratory Applications

Chemicals and laboratory reagents often require cold storage conditions to remain stable. Industries that handle volatile substances rely on cold rooms to ensure safe storage and compliance with regulatory standards.

4. Floral and Horticultural Industry

Florists and horticulturists use cold storage to extend the life of cut flowers and delicate plants. Optimized temperature and humidity levels help maintain the quality of these products until they reach consumers.

Benefits of Using Cold Rooms

The advantages of utilizing cold rooms are substantial for businesses that manage perishable items. Here are some notable benefits:

1. Extended Shelf Life

Maintaining products at optimal temperatures significantly extends their shelf life, allowing businesses to reduce waste and save costs.

2. Enhanced Quality Control

By preventing spoilage and degradation, cold rooms help businesses ensure that their products meet quality and safety standards, which is vital for maintaining customer trust.

3. Regulatory Compliance

Many industries are subject to strict regulations regarding the storage of sensitive materials. Cold rooms provide a means to comply with safety standards set by health authorities.

4. Flexibility and Space Optimization

Modern cold storage solutions can be designed to fit various business needs, optimizing space while providing flexibility for changes in inventory levels.

Challenges of Cold Rooms

Despite their numerous benefits, cold rooms also present certain challenges that need to be managed effectively.

1. Initial Capital Investment

Establishing a cold room requires a significant upfront investment in infrastructure, technology, and equipment, which may be a barrier for smaller businesses.

2. Energy Consumption

Cold rooms can consume substantial energy, leading to increased operational costs. Implementing energy-efficient solutions and renewable energy options can mitigate this issue.

3. Maintenance and Monitoring

Regular maintenance is paramount to ensure that cold storage remains functional and efficient. Businesses must invest in monitoring systems and scheduling maintenance to prevent unexpected failures.

Future Trends in Cold Storage

As the demand for cold storage continues to rise, several trends are shaping the future of this vital industry:

1. Technological Integration

With advancements in IoT, AI, and automation, cold storage facilities are becoming increasingly sophisticated, allowing for enhanced monitoring and predictive maintenance.

2. Sustainability Efforts

The push for eco-friendly practices is prompting many businesses to adopt energy-efficient systems and refrigerants with lower environmental impacts.

3. E-commerce Growth

The rapid expansion of the e-commerce sector demands more reliable cold chain logistics, driving innovations in transportation and storage solutions.

Frequently Asked Questions (FAQ)

What is the average temperature of a cold room?

The average temperature of a cold room typically falls between 32°F to 50°F (0°C to 10°C) for refrigeration rooms, while freezer rooms operate below 0°F (-18°C).

How long can food be stored in a cold room?

The storage duration depends on the type of food. For instance, fresh fruits can last several weeks, while meats may last a few days to weeks, depending on the conditions in the cold room.

Do cold rooms require special ventilation?

Yes, cold rooms require proper ventilation to prevent moisture buildup and ensure efficient operation of the refrigeration system. However, the design must ensure that outside air does not compromise the internal temperature.

Can I install a cold room myself?

Though small-scale cold rooms can be installed by individuals with adequate knowledge of refrigeration systems, it is generally best to hire professionals for the installation of larger units to meet compliance and safety standards.

What are the energy-saving measures for cold rooms?

Energy-saving measures for cold rooms include using energy-efficient refrigeration equipment, regularly maintaining the systems, improving insulation, and installing monitoring systems to optimize operations.

Conclusion

Cold rooms are fundamental in numerous sectors, providing essential solutions for preserving perishable items and sensitive materials. By understanding the types, components, and benefits of cold storage solutions, businesses can make informed decisions to enhance their operations and ensure product safety. As technology evolves and energy efficiency becomes paramount, the future of cold rooms looks promising, with advancements paving the way for more effective and sustainable practices in cold storage.