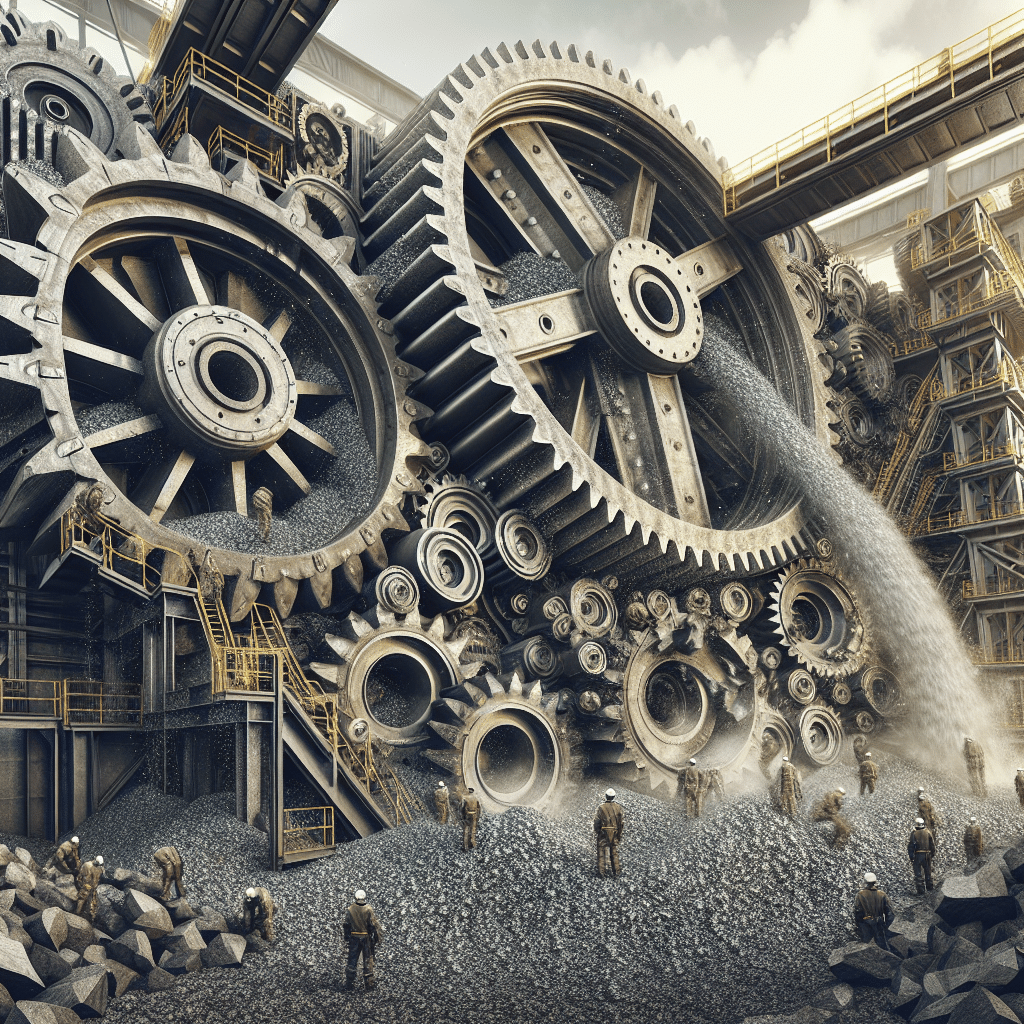

The crushing process is a mechanical method used to reduce the size of raw materials such as rocks, ores, and aggregates into smaller, manageable pieces. This operation is essential across various industries, including mining, construction, and recycling, facilitating easier processing and transportation. Through various methods such as jaw crushing, cone crushing, and impact crushing, materials are broken down to desired sizes while enhancing their chemical and physical properties. The crushing process often involves principles of physics and engineering to achieve efficiency, thereby playing a critical role in resource management and environmental sustainability.

Understanding the Crushing Process

The crushing process is fundamental in various industries as it transforms raw materials into smaller, usable sizes. This section will delve into the intricacies of the crushing process, the types of crushing equipment and methods used, and its importance in industrial applications.

1. The Principles of Crushing

Crushing primarily relies on mechanical forces to break down large materials. There are several key principles involved in this process:

- Compression: This method involves applying force to reduce material size by squeezing it together. Jaw crushers exemplify this principle.

- Impact: This technique relies on impacting the material to break it apart, commonly employed in impact crushers.

- Shearing: This method involves cutting or slicing the material, often used in hammer mills.

Understanding these principles allows operators to choose the right crushing technique based on the material type and desired end product.

2. Types of Crushing Equipment

Different types of crushing equipment are available, tailored to specific materials and desired outputs.

2.1. Jaw Crusher

The jaw crusher is one of the most common types of crushing equipment used in the industry. It operates by crushing materials between two surfaces, typically made of steel. The primary function is to break large rocks into smaller fragments for further processing.

2.2. Cone Crusher

The cone crusher is utilized for secondary and tertiary crushing stages. It provides more finely crushed material due to its design, which approximates a cone shape, facilitating even distribution of force.

2.3. Impact Crusher

Impact crushers utilize high-velocity impacts to crush materials. This makes them particularly effective for softer materials, resulting in a more cubical product.

2.4. Hammer Mill

A hammer mill employs high-speed rotating hammers to shred materials. This type of crusher is typically used for reducing materials to finer particles.

3. Stages of the Crushing Process

The crushing process generally consists of several stages, ensuring that the final product is suitable for its intended use.

3.1. Primary Crushing

The first stage involves breaking the large rock fragments into manageable pieces. Jaw crushers or gyratory crushers are typically preferred in this stage.

3.2. Secondary Crushing

Secondary crushing utilizes cone and impact crushers to further reduce material size. At this stage, the focus is on refining the material for better usability.

3.3. Tertiary Crushing

Tertiary crushing aims to produce a fine end product. This stage may employ specialist equipment, such as high-efficiency impact crushers.

4. Applications of the Crushing Process

The crushing process is integral to various sectors:

4.1. Mining Industry

In mining, crushing prepares ores for extraction and further processing, significantly impacting efficiency and recovery rates. Proper crushing techniques enhance the liberation of valuable minerals.

4.2. Construction Sector

Construction relies on crushed materials for producing concrete, asphalt, and other aggregates, demonstrating how this process directly impacts infrastructure development.

4.3. Recycling

The crushing process plays a vital role in recycling by reducing waste materials into smaller sizes, facilitating easier handling and processing into new products.

5. Environmental Considerations

While the crushing process is essential, it also raises environmental concerns. Dust generation, noise pollution, and landscape alteration are some of the significant issues associated with crushing activities.

Industry best practices advocate for the implementation of dust suppression systems, noise reduction technologies, and careful site selection to minimize environmental impacts. Additionally, advancements in technology have led to more energy-efficient and environmentally friendly crushing solutions.

6. FAQs

What materials can be crushed?

Various materials can be processed through crushing, including rocks, ores, concrete, asphalt, and even plastics, depending on the type of crushing equipment used.

How do I choose the right crushing equipment?

Selecting the appropriate crushing equipment involves considering factors such as material type, desired particle size, and the overall processing goal. Consulting with industry experts can help optimize results.

Is crushing harmful to the environment?

While crushing can produce environmental challenges like dust and noise, implementing best practices such as dust suppression and noise barriers can mitigate these effects. Responsible management is crucial to minimizing the impact.

What are the costs associated with the crushing process?

Costs vary based on equipment selection, operational labor, maintenance, and energy consumption. Businesses should conduct a thorough cost-analysis to determine the most economical crushing solutions.

Conclusion

The crushing process is a vital operation across multiple industries, facilitating the transformation of raw materials into usable sizes. Understanding this process’s various types of equipment, applications, stages, and environmental considerations will enable industry stakeholders to make informed decisions that optimize efficiency and sustainability in operations.