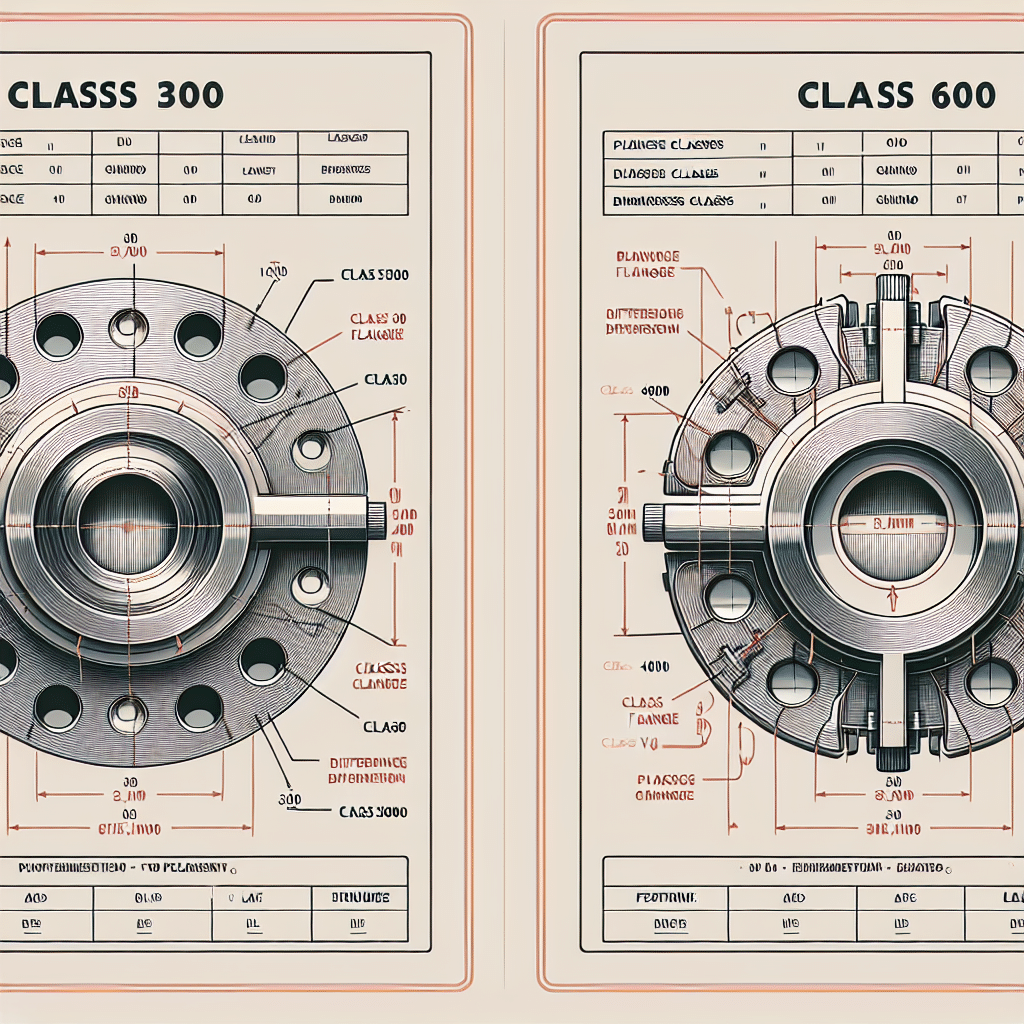

When it comes to industrial piping and equipment, understanding the specifications of flanges is essential for ensuring the compatibility and reliability of various components. The primary difference between class 300 and class 600 flanges lies in their pressure ratings and dimensions. Class 300 flanges are designed to withstand a maximum working pressure of 740 psi at 100°F, while class 600 flanges can handle up to 1,480 psi at the same temperature. This substantial difference in pressure capacity impacts the materials, thickness, and uses of these flanges in different applications. As industries demand greater safety and efficiency, knowing which flange class to use becomes crucial for engineers and procurement specialists. This article delves into the structural characteristics, applications, material standards, and key considerations when selecting between class 300 and class 600 flanges, helping you make informed decisions for your project.

Understanding Flange Classes

A flange is a mechanical component used to connect two sections of pipe, enabling the flow of fluids or gases. Flanges are classified based on their pressure-temperature ratings, dimensions, and material types. The American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) set these standards, with the rating system based on the maximum pressure and temperature the flange can withstand. Typically, the flange classes are identified by numbers, such as class 150, 300, 600, etc.

Pressure Ratings and Dimensions

Class 300 Flanges

Class 300 flanges are commonly used in industries for moderate pressure applications. They have a rated pressure of 740 psi at 100°F and a temperature limit that varies depending on the materials used. The dimensions for class 300 flanges are defined by the ANSI/ASME B16.5 standard. Here’s a quick overview of the dimensions:

- Diameter: Available in sizes ranging from 1/2 inch to 24 inches.

- Thickness: The thickness varies based on the diameter and can be between 0.25 to 0.75 inches.

- Material Options: Common materials include carbon steel, stainless steel, and alloy steel.

Class 600 Flanges

Class 600 flanges are designed for higher pressure applications. Rated for up to 1,480 psi at 100°F, these flanges require more robust materials and can be significantly thicker than class 300 ones. Their dimensions also follow the ANSI/ASME B16.5 standard, and here are some specifics:

- Diameter: Sizes typically range from 1/2 inch up to 24 inches, similar to class 300.

- Thickness: Generally, these flanges may vary in thickness from 0.25 to 1.50 inches depending on the size.

- Material Options: Commonly made from carbon steel, stainless steel, and other alloys.

Key Differences

Pressure Handling Capacity

The most significant difference between class 300 and class 600 flanges is their ability to handle pressure. Class 600 flanges are meant for high-pressure scenarios, making them preferable for heavy-duty applications.

Material and Design Considerations

Due to the higher pressure rating, class 600 flanges often require thicker and stronger materials for construction. This impacts not only the price but also the overall installation and maintenance processes.

Applications

Class 300 flanges are often utilized in applications such as:

- Water treatment facilities

- Pumping stations

- Heating systems

In contrast, class 600 flanges are commonly found in:

- Oil and gas pipelines

- Marine applications

- High-pressure steam systems

Material Standards

Both flange classes adhere to material specifications set by standards organizations. Common standards include ASTM A105 for carbon steel and ASTM A182 for forged stainless steel. Understanding these standards is vital for ensuring that your application meets regulatory and operational requirements.

Installation Considerations

Installation of flanges involves various factors, such as bolt type, gasket material, and torque specifications, which are critical for sealing and ensuring no leaks occur during operation. Class 600 flanges often require special considerations in installation due to their higher pressure demands.

FAQs

What is the maximum pressure for class 300 and class 600 flanges?

The maximum pressure for class 300 flanges is 740 psi, while class 600 flanges can handle up to 1,480 psi at 100°F.

Can class 300 flanges be used in high-pressure applications?

While class 300 flanges can handle moderate pressure, they are not recommended for high-pressure applications where class 600 flanges are more suitable.

Are class 300 and class 600 flanges interchangeable?

No, due to their different pressure ratings and dimensions, class 300 and class 600 flanges should not be interchanged without proper assessment of the application requirements.

What materials are commonly used in both flange types?

Common materials for both flange types include carbon steel, stainless steel, and various alloys, with material choice depending on the specific application conditions.

Conclusion

Understanding the difference between class 300 and class 600 flanges is crucial for selecting the right components for your piping systems. Factors such as pressure rating, material strength, and application suitability should guide your decision-making process to ensure operational efficiency and safety. Always consult with industry standards and experts when choosing flanges to match the needs of your project.