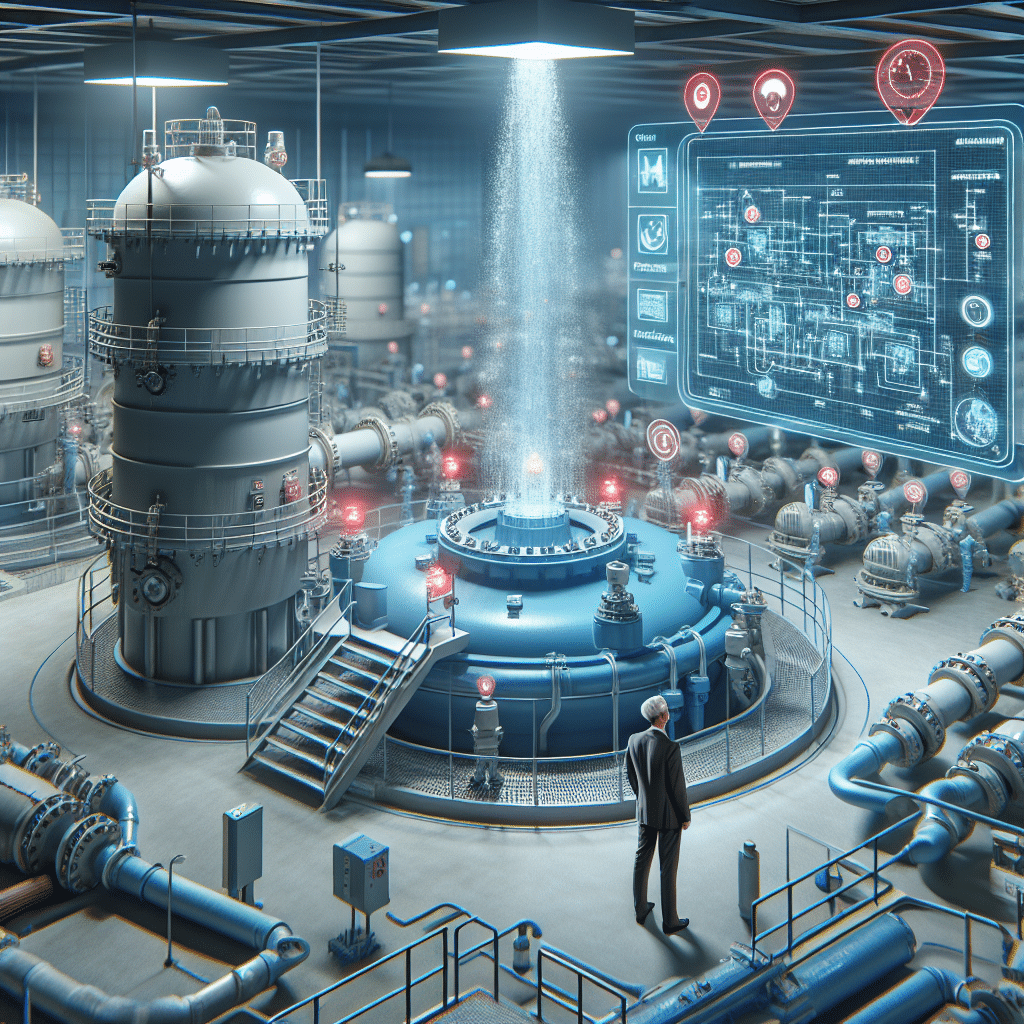

If water suction pressure is too high, it can lead to several critical issues within plumbing and fluid systems. High suction pressure can cause hydraulic shock, which may damage pipes, fittings, and equipment. It can also lead to cavitation in pumps, resulting in premature wear or catastrophic failure. Additionally, excessively high suction pressure can create inefficiencies within pumping systems, increasing operational costs and risking system integrity. Therefore, it is essential to monitor and maintain appropriate suction pressure levels to ensure optimal performance and longevity of equipment.

Understanding Water Suction Pressure

Water suction pressure refers to the pressure applied to draw water into a system, particularly in pumps and plumbing applications. It is typically measured in pounds per square inch (PSI) or kilopascals (kPa). Various factors influence suction pressure, including the type of pump, the elevation difference between the water source and the pump, and the overall friction losses within the system.

Factors Contributing to High Suction Pressure

Several factors can lead to high suction pressures in water systems:

- Pump Sizing: Over-sizing a pump for a specific application can result in higher than necessary suction pressure.

- Elevation Changes: If water must travel uphill to reach the pump, the elevation difference can increase the suction pressure.

- Fluid Viscosity: Thicker fluids exert more resistance, leading to higher suction pressures.

- Blockages: Debris or blockages in pipes can cause a pressure buildup before the pump.

Impacts of High Suction Pressure

When suction pressure exceeds the recommended levels, it can pose several risks:

1. Hydraulic Shock

Hydraulic shock, often referred to as water hammer, occurs when there is a sudden change in fluid velocity, causing shockwaves in the system. High suction pressures can amplify these effects, potentially leading to:

- Pipe bursts or ruptures

- Connection failures

- Damage to valves and fittings

2. Cavitation in Pumps

Cavitation occurs when the local pressure in a pump falls below the vapor pressure of the liquid, leading to the formation of vapor bubbles. These bubbles collapse violently, which can lead to:

- Severe erosion of pump components

- Reduced efficiency and performance

- Increased maintenance and repair costs

3. Decreased System Efficiency

Your pumping system may become less efficient with high suction pressure, resulting in:

- Increased energy consumption

- Higher operational costs

- Potential for overheating in motor-driven systems

4. Increased Risk of Equipment Failure

Continually operating under high suction pressure can increase the likelihood of equipment failure. Components may suffer from:

- Fatigue due to excessive mechanical stress

- Premature wear and tear

- Overall reduction in lifespan of machinery

Solutions for Managing Suction Pressure

Maintaining optimal suction pressure is crucial for system performance. Consider these strategies:

1. Proper Sizing of Equipment

Choose pumps that are appropriately sized for your application to prevent excessive suction pressures from occurring.

2. Regular Maintenance and Inspections

Conduct routine inspections to check for blockages and wear in the system. Proactive maintenance can help anticipate and mitigate issues before they escalate.

3. Installation of Pressure Relief Valves

Implementing pressure relief valves can protect your system by automatically reducing excessive suction pressures when detected.

4. Optimization of System Design

Designing systems for ideal flow conditions, including minimizing altitude changes and bends, can help maintain appropriate suction levels.

FAQs

What is the ideal suction pressure for water pumps?

While it can vary based on application, most water pumps operate effectively at suction pressures ranging from 10 to 20 PSI. Always consult the manufacturer’s specifications for your specific equipment.

How can I tell if my system has high suction pressure?

Signs of high suction pressure may include unusual noises from pumps, fluctuations in flow rate, or visible leaks in your piping system. Monitoring gauges regularly can also help you identify irregular pressure levels.

Can high suction pressure cause leaks?

Yes, excessive suction pressure puts additional stress on joints, fittings, and pipe materials, increasing the likelihood of leaks forming over time.

What maintenance practices can help prevent high suction pressure?

Routine system checks for blockages, regular cleaning, timely replacement of worn equipment, and ensuring proper pump application are effective practices to prevent high suction pressure.

Conclusion

Understanding and managing water suction pressures are crucial for the reliability and efficiency of any hydraulic system. By recognizing the signs of excessive pressure and implementing preventive measures, you can protect your investment and ensure optimal operational performance. Keeping your systems running smoothly not only saves money but also fosters a sustainable approach to water management.