PCB Quote Packing is a crucial aspect of electronic engineering, specifically dealing with the design, manufacturing, and packaging of printed circuit boards (PCBs). This discipline encompasses various engineering principles, including materials science, mechanical engineering, and systems engineering. The process of PCB quote packing involves consolidating the technical specifications, costs, and logistics needed for producing PCBs while ensuring they meet industry standards and customer needs. Understanding these engineering facets is essential for optimizing production efficiency, cost-effectiveness, and product reliability. A well-structured PCB quote can significantly affect the manufacturing workflow, quality assurance processes, and overall project success. Therefore, mastering this art requires a blend of technical expertise, analytical skills, and effective communication with stakeholders.

1. Understanding PCB Quote Packing

PCB quote packing refers to the systematic process of gathering, analyzing, and presenting all relevant information and specifications needed for producing printed circuit boards. This encompasses various elements, including:

- Technical Specifications: These include details such as layer count, size, thickness, surface finish, and materials used.

- Cost Analysis: This involves estimating the manufacturing costs per unit, including materials, labor, shipping, and any additional fees.

- Logistics: This covers timelines, supplier selection, and any necessary certifications or compliance requirements.

In essence, PCB quote packing serves as a bridge between the design requirements and the production processes, requiring a blend of skills across multiple engineering disciplines.

2. The Role of Various Engineering Disciplines in PCB Quote Packing

2.1 Electrical Engineering

Electrical engineering plays a significant role in determining the functionality of PCBs. The engineers must ensure that the design meets electrical performance requirements, including power distribution, signal integrity, and noise considerations. They work to specify the appropriate components, such as resistors, capacitors, and microchips, and how these components interact on the board.

2.2 Mechanical Engineering

Mechanical considerations are critical in PCB packaging. Mechanical engineers ensure that the PCB design can withstand the physical conditions it will encounter, such as thermal expansions, vibrations, and physical stresses. They evaluate the layout for its robustness and functionality and consider factors like thermal management and mechanical support.

2.3 Materials Science

Understanding the materials that make up PCB components is vital for ensuring durability and reliability. Materials engineers select suitable substrates, such as FR-4 or polyimide, depending on the application requirements, including thermal, mechanical, and electrical properties.

2.4 Systems Engineering

The art of managing complex systems is where systems engineering steps in. Specialists in this field ensure that all aspects of PCB production—the design, manufacturing, and packaging processes—work cohesively. They apply principles of project management to streamline workflow, optimize resource allocation, and ensure that the project aligns with specific objectives.

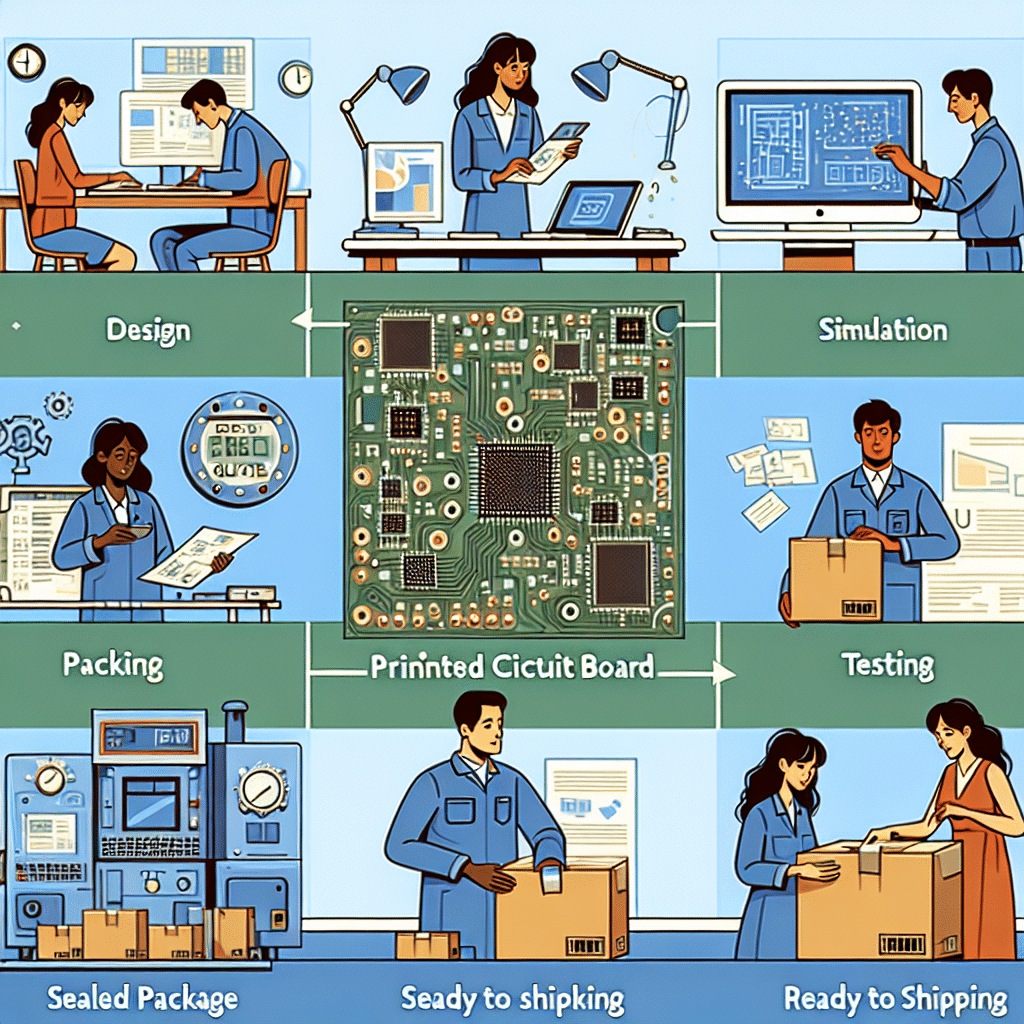

3. Detailed Steps in PCB Quote Packing

Let’s break down the procedures followed in PCB quote packing in detail:

3.1 Gathering Initial Data

The process begins with collecting all necessary data regarding the PCB project, including:

- Client requirements and specifications

- Functionality expectations and performance standards

- Budget constraints and expectations for delivery timelines

3.2 Design Specifications

Based on the data gathered, electrical engineers create a schematic design that outlines the component layout and the connections between them. This design must comply with industry standards (such as IPC standards) for reliability and performance.

3.3 Cost Estimation

Once the design is established, engineers proceed with cost estimation by analyzing factors that contribute to the overall price of manufacturing PCBs, including:

- The material costs of substrates and components

- Labor costs associated with manufacturing and assembly

- Machining, tooling, and setup fees

- Shipping costs and any import/export duties

3.4 Supplier Selection

Selecting the right suppliers is critical. Engineers must evaluate multiple suppliers based on:

- Quality of materials

- Previous performance metrics

- Availability and lead times

3.5 Quote Compilation

All gathered information is then compiled into a formal quote document. This document should be comprehensive, clear, and understandable, detailing the project scope, timelines, costs, and terms of service. It must also present any assumptions made during the estimation process.

3.6 Client Presentation

The final step is to present the quote to the client, ensuring transparency in both pricing and timelines. Feedback from clients is incorporated, requiring revisiting earlier steps if needed, thereby fostering a collaborative approach.

4. Common Challenges in PCB Quote Packing

Despite the systematic approach, several challenges may arise during PCB quote packing:

4.1 Rising Material Costs

The electronic components market experiences fluctuating prices, impacting the cost estimates. Engineers must stay informed about market trends to provide accurate quotes.

4.2 Component Availability

Global supply chain disruptions can hinder component sourcing, leading to delays that affect production timelines.

4.3 Design Changes

Clients may modify specifications after the quote has been presented, complicating the manufacturing process and requiring adjustments in timelines and costs.

5. Importance of PCB Quote Packing

The importance of efficient PCB quote packing cannot be overstated. A well-formulated quote leads to:

- Cost Efficiency: Accurate costing helps in controlling budgets.

- Time Management: Clear timelines contribute to better project management.

- Enhanced Communication: Structured documentation simplifies discussions with clients and stakeholders.

6. Future Trends in PCB Quote Packing

The PCB industry is rapidly evolving, and with it, the techniques used in quote packing. Several trends are emerging:

6.1 Automation and Software Solutions

Recent advancements in software solutions are streamlining the quote packing process. Automated systems that integrate design, cost estimation, and supply chain management can enhance accuracy and efficiency.

6.2 Sustainable Practices

Environmental considerations are increasingly influencing PCB manufacturing processes. Engineers are exploring eco-friendly materials and practices, which in turn affect the quoting process by introducing new parameters for cost and sourcing.

7. FAQ Section

7.1 What is PCB quote packing?

PCB quote packing is the process of gathering and presenting detailed information regarding the design, cost estimation, and logistics for producing printed circuit boards.

7.2 Why is PCB quote packing important in engineering?

This process is essential for ensuring cost-effectiveness, efficiency in production timelines, and clear communication with clients, ultimately contributing to project success.

7.3 What challenges can arise during PCB quote packing?

Common challenges include rising material costs, component availability issues, and late design changes from clients.

7.4 How can software improve PCB quote packing?

Automation and advanced software solutions can streamline the quoting process, enhance accuracy, and integrate various aspects such as design and supply chain management.

7.5 What future trends are shaping PCB quote packing?

Future trends include increased automation, sustainable practices, and evolving software technologies that improve efficiency and responsiveness in the quote packing process.

In conclusion, PCB quote packing represents a multifaceted intersection of various engineering disciplines, requiring precision, collaboration, and strategic planning. As technology advances, so too will the methodologies in PCB quote packing, ensuring a continued evolution in how printed circuit boards are designed and produced.