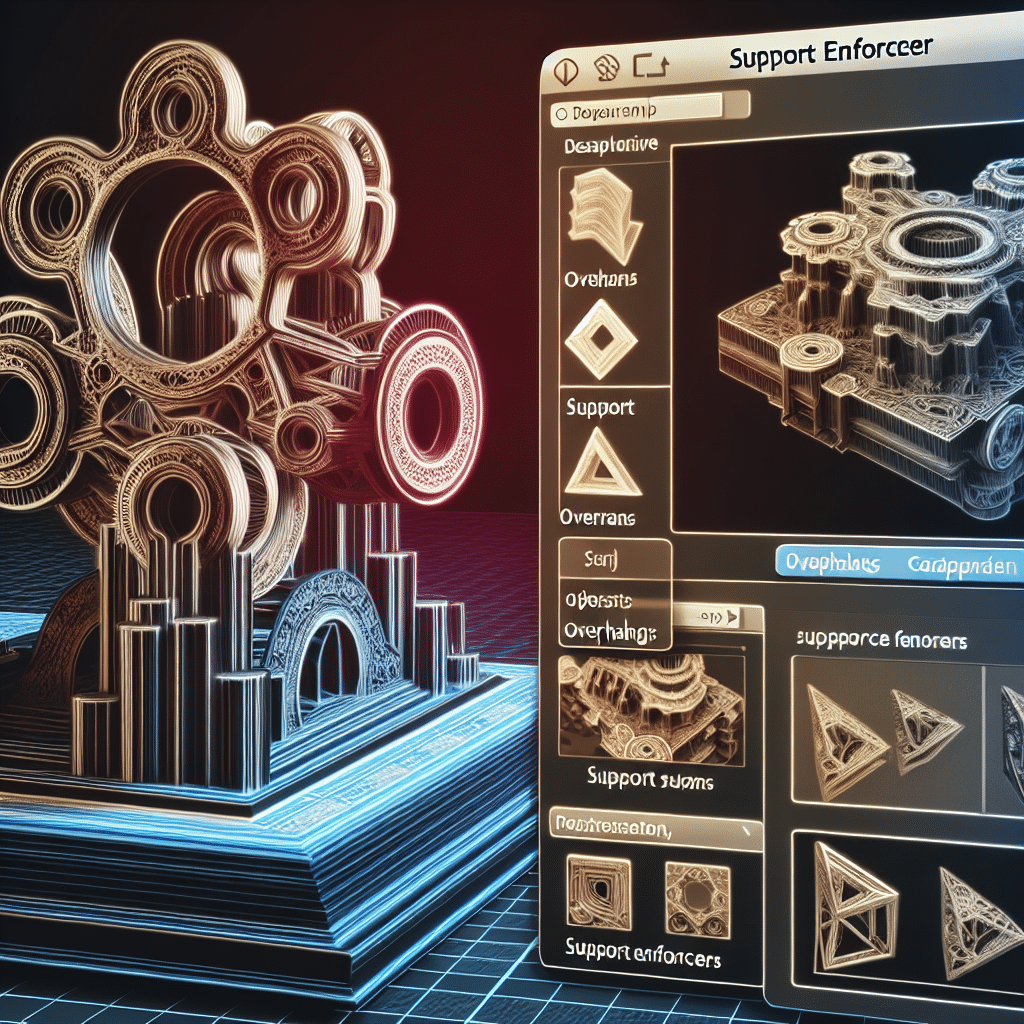

Introduction to Support Enforcers in PrusaSlicer

Support enforcers are a powerful feature in PrusaSlicer that allow users to enhance their 3D printing experience by controlling where and how support structures are generated. They provide a way to manually dictate support for specific parts of a model, ensuring better surface finish and reliability of prints in complex designs. By strategically placing these enforcers, you can ensure that areas requiring additional support receive it, while minimizing unnecessary support material in less critical areas. This not only streamlines the printing process but also aids in post-processing, yielding cleaner results. Understanding and utilizing support enforcers can significantly enhance the quality and success rate of your 3D prints.

Understanding Support Enforcers

Support enforcers are essentially mesh bodies that you can add to your model in PrusaSlicer. They dictate where support material should be generated during the printing process. Users can add these enforcers to the build plate or specific locations on the print to enhance support in particular areas without affecting the overall support structure for the entire model. The result is optimized use of support filament, reduced material waste, and improved print quality.

The Importance of Support Structures

In 3D printing, especially with FDM (Fused Deposition Modeling) technology, support structures are essential for printing overhangs and bridging qualities. Areas of a model that extend beyond the main body often require additional support to maintain structural integrity throughout the printing process. By implementing support enforcers, you gain finer control over these necessary structures, leading to more durable and aesthetically pleasing finished products.

How to Use Support Enforcers in PrusaSlicer

Using support enforcers in PrusaSlicer is straightforward. Here’s a step-by-step guide:

- Open PrusaSlicer: Launch the software and load your 3D model.

- Add a Support Enforcer: Navigate to the object placement tab and select “Add Support Enforce.” This will allow you to draw a custom shape on your model where you want additional support.

- Adjust the Size and Position: Resize and place the enforcer mesh precisely where you need it. You can modify the width, height, and area covered by dragging the control points.

- Slice the Model: After placing the enforcer, click on the “Slice Now” button. PrusaSlicer will regenerate the support structure according to your specifications.

- Review the Preview: Always check the layer preview to ensure that the support enforcer is correctly influencing the support generation.

Best Practices for Using Support Enforcers

While support enforcers are a versatile tool, there are best practices you should keep in mind to optimize their usage:

- Use Minimal Material: Only place enforcers where absolutely necessary to reduce material usage and post-processing time.

- Experiment with Settings: Test various sizes and shapes of support enforcers to find the optimal configuration for each specific model.

- Analyze Results: After printing, assess the quality of the supports created by the enforcers and adjust your methods as necessary.

Common Challenges and Solutions

Despite their numerous benefits, users may encounter challenges while using support enforcers. Here are some common issues and potential solutions:

- Support Excess or Insufficient Support: If you notice excess support structures or insufficient support, carefully adjust the size and placement of your enforcers based on the geometry of your model.

- Post-Processing Difficulty: If removing supports becomes troublesome, consider tweaking the support density or exploring better-enforced configurations that still hold up the print but are easier to remove.

FAQs about Support Enforcers in PrusaSlicer

What are support enforcers?

Support enforcers are additional mesh bodies that you can add to your 3D model in PrusaSlicer to specify areas that require extra support structures during the printing process.

How do I add support enforcers in PrusaSlicer?

To add support enforcers, open your model, select “Add Support Enforcer” in the object placement tab, and then customize the size and position of the enforcer as needed.

Can I adjust the settings of support enforcers?

Yes, you can adjust the size, shape, and position of support enforcers to suit your printing requirements better. Experimenting with these settings will help achieve optimal results for your prints.

Do support enforcers affect print time?

Yes, adding support enforcers can potentially affect print time. However, they can reduce print failure rates and post-processing time by ensuring adequate support, which may save overall project time.

Are support enforcers necessary for all models?

No, support enforcers are not necessary for every model. Their use depends on the specific shape and complexity of the object being printed. Always evaluate your model’s design before deciding on the need for support enforcers.

Conclusion

Understanding and effectively utilizing support enforcers in PrusaSlicer is essential for optimizing the 3D printing process. These tools allow you enhanced control over the use of support materials, reducing waste and improving print quality. By following best practices, experimenting with different configurations, and analyzing outcomes, you can significantly elevate your 3D printing projects for successful and satisfying results. Embrace the power of support enforcers to ensure that your prints are both structurally sound and aesthetically pleasing!