Saw Surface Acoustic Wave (SAW): What is Bar?

Surface Acoustic Wave (SAW) bars are essential components in various electronic devices, enabling communication and signal processing across industries. They function based on the principles of piezoelectricity where an acoustic wave travels along the surface of a material—typically quartz or lithium niobate. The design of a SAW device typically incorporates interdigitated transducers (IDTs), which generate and detect these acoustic waves, allowing for frequency filtering, timing, and signal processing applications.

These devices are highly valued for their compact size, reliability, and efficiency in processing signals, making them crucial for applications in telecommunications, radar technology, and even consumer electronics. Understanding SAW bars involves delving into their operational principles, design considerations, and diverse applications, ensuring their importance in modern technology is thoroughly appreciated.

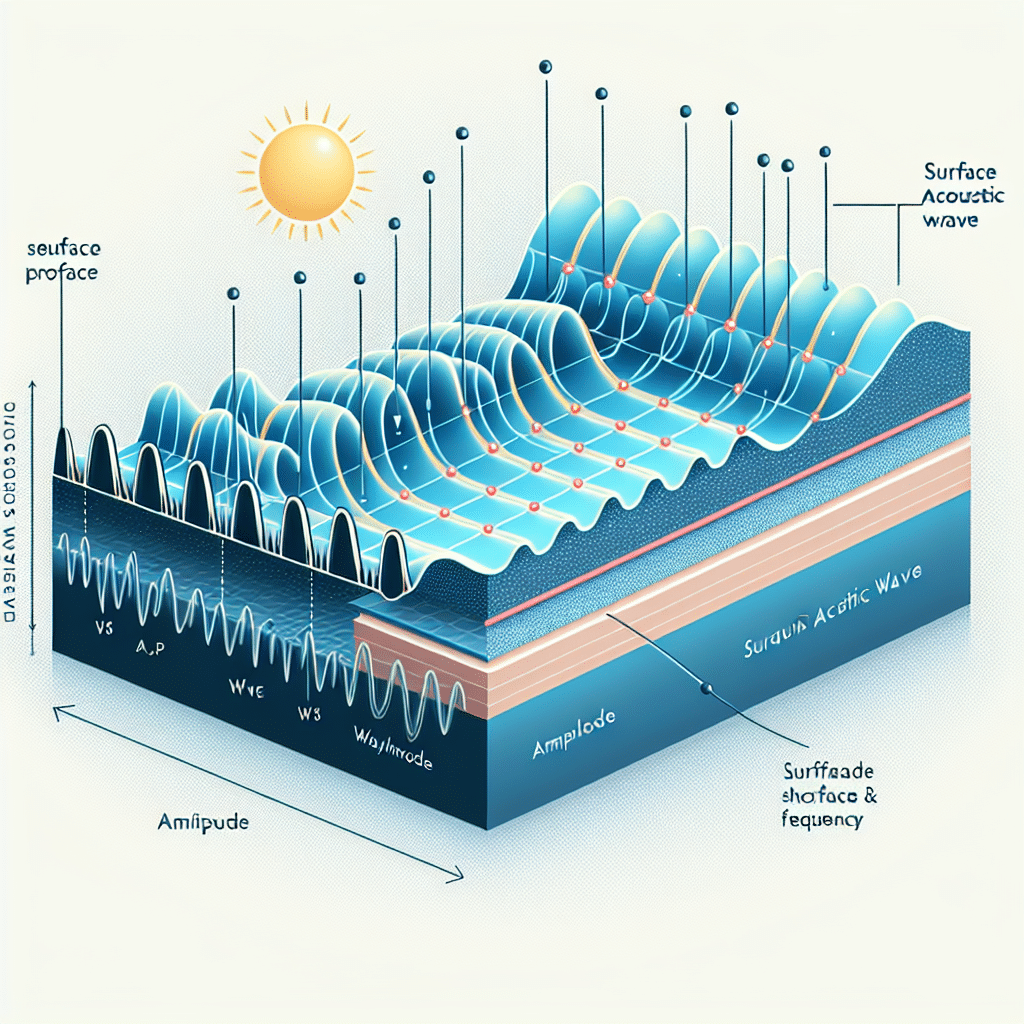

Understanding Surface Acoustic Waves

To grasp the functionality of Surface Acoustic Wave (SAW) bars, you must first understand the fundamental concept of surface acoustic waves themselves. These waves are mechanical waves that travel along the surface of elastic materials, characterized by their ability to propagate energy across various distances while maintaining the integrity of the wave form. This property makes SAW technology advantageous in numerous applications.

How SAW Waves Work

Surface acoustic waves are generated when an alternating voltage is applied to a piezoelectric material. This voltage causes the surface of the material to deform, which, in turn, generates an acoustic wave that travels across the surface. Key to this process are interdigitated transducers (IDTs)—key components that convert electrical signals into mechanical waves and vice versa. The interaction between the generated surface waves and the electrodes on the substrate allows for efficient signal manipulation.

The Structure of a SAW Device

The basic structure of a SAW device typically includes:

- Substrate: Usually made from piezoelectric materials such as quartz, lithium tantalate, or lithium niobate, which support the propagation of acoustic waves.

- Interdigitated Transducers (IDTs): These are crucial for converting electrical signals into surface acoustic waves. Their design significantly impacts the performance characteristics of the SAW device.

- Reflectors: Often included to reflect and focus the acoustic waves at specific frequencies, improving efficiency and frequency selectivity.

Applications of SAW Devices

SAW devices are deployed in various fields due to their versatility and reliability. Some common applications include:

Telecommunications

In the telecommunications sector, SAW filters are employed in mobile phones and base stations to manage frequency channels and suppress unwanted signals. Their small size and effectiveness at high frequencies make them ideal for compact, mobile devices.

RFID Technology

SAW technology is also integral to RFID (Radio-Frequency Identification) tags, where they facilitate precise communication by modulating signals according to the acoustic waves generated. This ensures accurate identification and tracking of objects.

Sensor Applications

SAW devices find applications in sensor technology, including temperature sensors and pressure sensors, due to their sensitivity and ability to detect minute changes in external conditions, enabling precise measurements in various industrial processes.

Benefits of Using SAW Technology

There are numerous advantages to utilizing SAW technology in electronic devices:

- Compact Size: SAW devices are significantly smaller than traditional electronic components, facilitating miniaturization in devices.

- High Performance: They provide high-performance capabilities for filtering, signal processing, and RF communication.

- Reliability and Durability: With no moving parts, SAW devices offer enhanced durability and reliability, making them suitable for a wide range of applications.

Challenges and Limitations

Despite numerous advantages, there are challenges associated with SAW devices:

- Material Limitations: The performance of SAW devices is highly dependent on the quality of the piezoelectric materials used, which can be costly.

- Frequency Limitations: While SAW devices excel at filtering and processing signals at certain frequencies, their efficacy can diminish at very high frequencies.

- Environmental Sensitivity: SAW devices can be sensitive to environmental factors such as temperature and humidity, which may affect performance.

Future Developments in SAW Technology

As technology evolves, so does the potential for SAW devices. Advancements may include:

- Integration with Nanotechnology: Combining SAW technology with nanomaterials can enhance their sensitivity and performance in various applications.

- Enhanced Signal Processing Capabilities: Future developments may lead to even more sophisticated algorithms and architectures for processing signals securely and efficiently.

Conclusion

Understanding SAW surface acoustic waves and their applications is crucial in today’s connected world. From telecommunications to sensor technology, SAW devices offer a myriad of benefits that are reshaping our interaction with technology. By comprehending the working principles, structures, applications, and future developments in SAW technology, professionals can anticipate innovations across various fields—leading to more efficient and effective solutions in electronic design and engineering.

FAQs

What materials are used in SAW devices?

Common materials for SAW devices include quartz, lithium tantalate, and lithium niobate, due to their piezoelectric properties that enable wave propagation.

Where are SAW devices commonly used?

SAW devices are primarily utilized in telecommunications, RFID systems, sensor technology, and various signal processing applications.

What are the advantages of SAW technology?

Advantages of SAW technology include compact size, high performance, reliability, and durability without moving parts, making them suitable for various environments.

What are the limitations of SAW devices?

Limitations include material costs, frequency restrictions, and sensitivity to environmental conditions, which can affect performance.

What is the future of SAW technology?

The future of SAW technology may involve the integration of nanotechnology and enhanced signal processing capabilities, leading to improved efficiency and application versatility.