Introduction

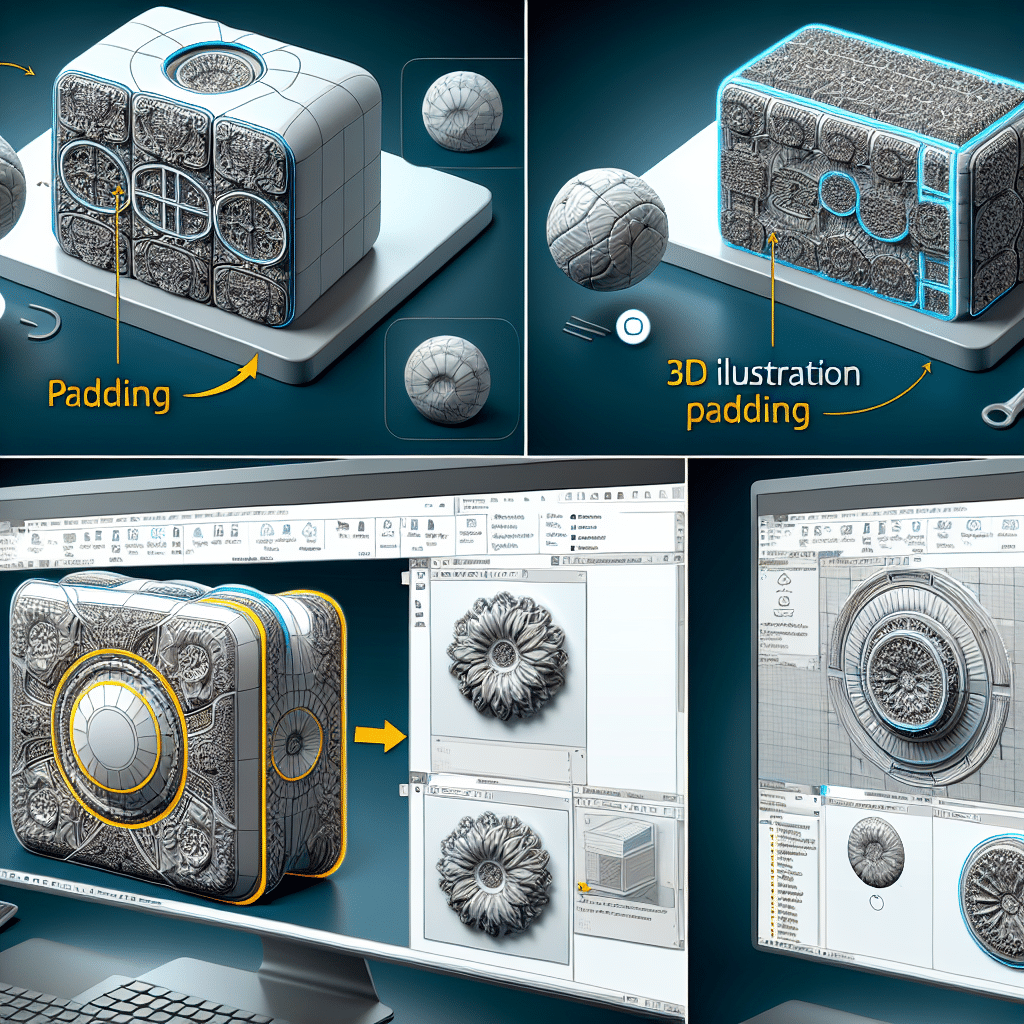

In SolidWorks, padding refers to the additional space or buffer that is added around an object, typically in the context of parts or assemblies to manage tolerances, fit, and clearance. It is essential when designing intricate parts that interface with one another, ensuring they are manufactured correctly without interference. Padding assists in achieving the necessary dimensional accuracy while accounting for variables such as thermal expansion, machining variations, and material characteristics. By utilizing padding effectively, engineers can optimize their designs for functionality and manufacturability, thereby enhancing performance and longevity.

Understanding Padding in SolidWorks

Padding plays a critical role in the realm of CAD design, especially within SolidWorks. It is a fundamental component that enables designers to cater to numerous specifications and constraints encountered during the design process. This section will explore the concept of padding in SolidWorks in detail, discussing its importance, applications, and best practices.

What is Padding?

Padding can be defined as the extra space added around the edges of a shape or between components in assemblies. In SolidWorks, padding ensures that components can fit together seamlessly without physical incompatibility during manufacturing or assembly. It contributes to dimensional tolerances and influences the overall quality of the finished product. Understanding how to apply padding correctly is crucial for every designer aiming to produce reliable and high-performing designs.

Applications of Padding in SolidWorks

Padding has various applications across different stages of the design and manufacturing process. Here are some key areas where padding is essential:

- Assembly Design: When creating assemblies, padding is crucial for ensuring components fit together without interference, allowing for smooth operation.

- Thermal Expansion Considerations: Designers can use padding to account for thermal expansion, ensuring that parts retain clearance under different temperature conditions.

- Manufacturing Tolerances: It acts as a buffer to compensate for manufacturing variances, promoting smoother production lines.

- Material Interaction: In assemblies where dissimilar materials are present, padding accommodates differences in expansion rates and other material properties.

Calculating Padding Values

When determining the amount of padding required, several factors must be taken into account, such as:

- Material Properties: Understanding the mechanical and physical properties of materials involved will guide the padding requirements.

- Environment: If the components will be exposed to significant temperature changes, additional padding may be needed.

- Tolerance Specifications: Consult engineering drawings to comply with industry standards and tolerances for both manufacturing and assembly.

Best Practices for Using Padding

To maximize the benefits of padding in SolidWorks design, consider the following best practices:

- Engage with Engineering Standards: Familiarize yourself with applicable standards and specifications that dictate padding requirements for your industry.

- Utilize Simulation Tools: SolidWorks offers simulation capabilities to test designs under realistic conditions. Use these to evaluate the performance of your design before finalizing.

- Iterate on Designs: Don’t hesitate to modify the padding as you progress. Continuous iteration ensures that your designs meet performance expectations without excessive material use.

Common Questions About Padding in SolidWorks

What is the difference between padding and clearance?

While both padding and clearance are related to the spacing and fit of components, padding refers specifically to the additional space designed into components to account for tolerances, whereas clearance is the actual space between two parts in an assembly.

How do I adjust padding in my SolidWorks project?

You can adjust padding within the part or assembly features by modifying the dimension parameters for the involved components. Utilize the Dimension tool to accurately adjust spacing according to your calculations.

Can padding affect the weight and cost of a part?

Yes, unnecessary padding can increase both material usage and manufacturing costs. Therefore, it is essential to calculate the required padding accurately to maintain efficiency.

Are there industry standards that guide padding requirements?

Yes, various industry standards, such as ISO and ASME, provide guidelines regarding tolerances and fits, which influence padding specifications to ensure uniformity across machining and assembly processes.

Conclusion

In summary, padding in SolidWorks serves as an indispensable element for achieving accurate, functional, and manufacturable designs. Proper implementation of padding allows designers to deal effectively with tolerances, environmental factors, and physical interactions between materials. By understanding and applying padding with care, you can significantly enhance the integrity and performance of your SolidWorks projects.