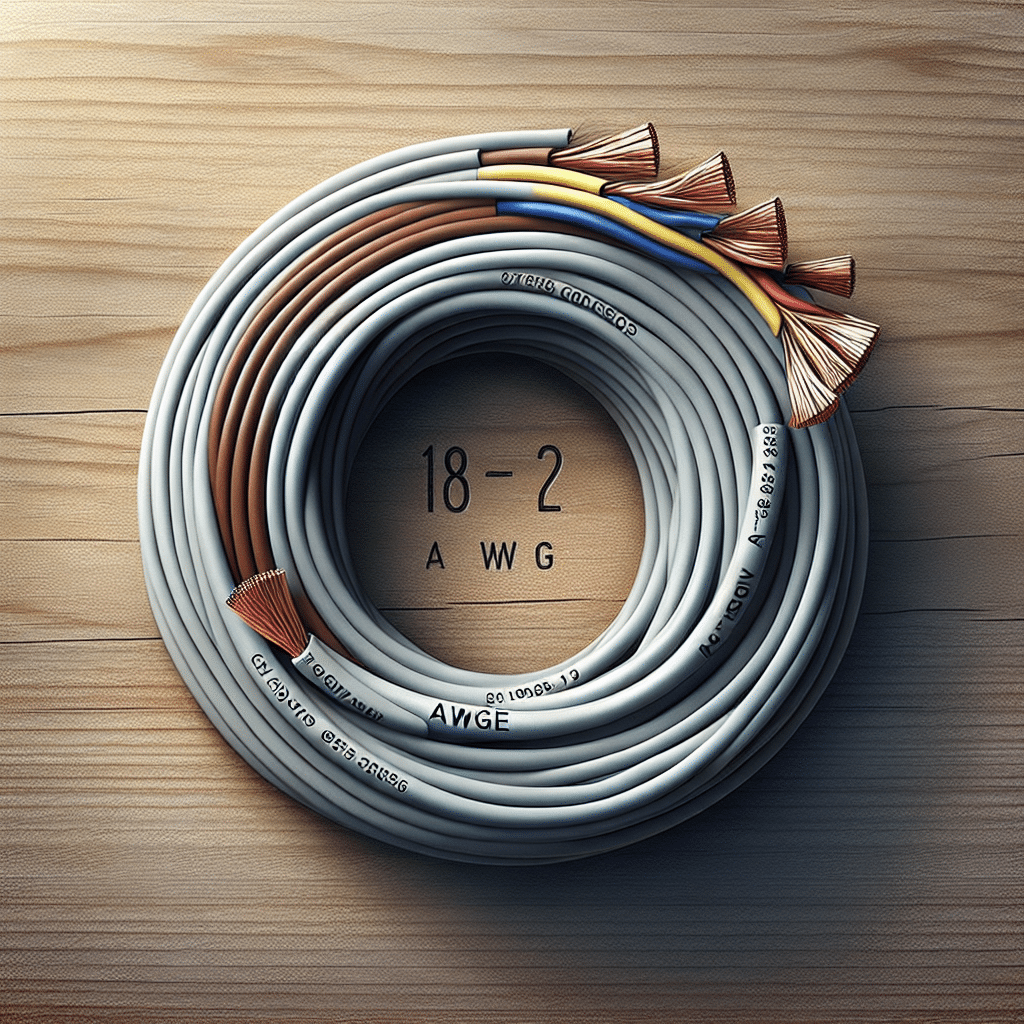

What is 18-2 AWG Wire?

18-2 AWG wire is a common type of electrical wire consisting of two conductors, each measuring 18 American Wire Gauge (AWG) in diameter. This wire is typically used for low-voltage applications, making it ideal for tasks such as connecting doorbells, alarm systems, and other low-current devices. The “2” in 18-2 indicates the presence of two conductors, which can be essential for applications requiring a positive and a negative connection. Made from materials like copper or aluminum, 18-2 AWG wire is characterized by its good conductivity and flexibility, making it easy to work with in various settings. Due to its multifunctional nature, 18-2 AWG wire is widely available and used across residential and commercial installations.

Understanding 18-2 AWG Wire: Specifications and Applications

Welcome to our comprehensive guide on 18-2 AWG wire. As electrical wiring continues to play a pivotal role in modern automation and safety, understanding its specifications, materials, applications, and potential drawbacks becomes vital for anyone involved in electrical work.

What Does 18-2 AWG Mean?

The term 18-2 AWG refers to a specific type of electrical wire characterized by several key features:

- Gauge: The “18” indicates that each conductor of the wire measures 18 gauge. This measurement is based on the American Wire Gauge system, which outlines the thickness of wire conductors.

- Conductors: The “2” signifies that the wire has two conductors. This configuration typically consists of a positive and a negative conductor.

- Material: Most 18-2 wires are made from copper due to its excellent electrical conductivity, though some may be made from aluminum.

Electrical Specifications

Here are some technical specifics surrounding 18-2 AWG wire:

- Diameter: The diameter of an 18 AWG wire is approximately 1.024 mm (0.0403 inches).

- Current Capacity: 18-2 AWG wire can typically handle up to 10 amps for a short duration and typically 5-7 amps for continuous applications.

- Voltage Rating: This wire is usually rated for up to 300 volts, making it suitable for low-voltage power applications.

Common Applications

When it comes to practical applications, 18-2 AWG wire is used in various instances:

- Alarm Systems: Widely utilized for security and fire alarm systems where low-voltage wiring is required.

- Doorbells: A typical choice for doorbell wiring, providing a reliable connection between the doorbell button and the chime.

- Low-Voltage Landscape Lighting: Often employed in landscape lighting systems where low-voltage requirements are crucial.

- Thermostats: Commonly used in HVAC systems to connect thermostats to heating or cooling units.

Advantages of Using 18-2 AWG Wire

Flexibility and Ease of Use: One of the primary benefits of 18-2 AWG wire is its flexibility, making it easy to bend and maneuver in tight spaces.

Cost-Effectiveness: Due to its common usage, 18-2 AWG wire is often readily available and economically priced, making it accessible for both DIY enthusiasts and professionals.

Choosing the Right Wire: Important Considerations

When deciding whether 18-2 AWG wire is the right fit for your project, consider the following:

- Voltage and Current Requirements: Ensure the voltage and current ratings align with your application.

- Length of Run: If the wire will run for an extended distance, voltage drop could be a concern, which may influence wire gauge selection.

- Environmental Conditions: Ensure the wire is rated for the conditions it will be exposed to (e.g., moisture, temperature extremes).

Potential Drawbacks

While 18-2 AWG wire is advantageous, it’s important to consider some limitations:

- Limited Current Capacity: It may not be suitable for high-current applications; exceeding the amperage could lead to overheating.

- Length Limitations: Voltage drop can become significant over long distances, limiting its effectiveness in larger installations.

Comparative Analysis: AWG Wire Sizes

To gain a better understanding of wire selection, comparing 18-2 AWG wire to other sizes can be beneficial:

| Gauge | Diameter (mm) | Current Capacity (Amps) | Typical Application |

|---|---|---|---|

| 16 AWG | 1.291 | 13 | Higher current applications, speakers |

| 18 AWG | 1.024 | 10 | Doorbells, alarm systems |

| 20 AWG | 0.812 | 5 | Low-power applications, electronics |

Installation Tips for 18-2 AWG Wire

For successful installation of 18-2 AWG wire, keep these tips in mind:

- Strip the Wire Properly: Use quality wire strippers to avoid damaging the conductors.

- Secure Connections: Ensure all connections are tight and use appropriate connectors to prevent failures.

- Follow Local Codes: Always adhere to the National Electrical Code (NEC) and local regulations to ensure safety and compliance.

FAQs About 18-2 AWG Wire

What is the maximum length for using 18-2 AWG wire?

The maximum length can depend on the current load and application, but generally, keep runs to less than 100 feet to minimize voltage drop for most low-voltage applications.

Can 18-2 AWG wire be used outdoors?

While it’s often not rated for direct burial, 18-2 AWG wire can be used outdoors if it’s properly insulated and protected from moisture and UV exposure.

Is 18-2 AWG wire suitable for LED lighting?

Yes, 18-2 AWG wire can be used for low-voltage LED lighting systems, provided the voltage and current specifications are suitable for the system you are using.

Can I connect multiple devices using 18-2 AWG wire?

Multiple devices can be connected, but be cautious about the total current load to avoid exceeding the wire’s amperage capacity, which could lead to overheating.

What tools are needed for working with 18-2 AWG wire?

Common tools include wire strippers, crimping tools, connectors, and basic screwdrivers. Ensuring proper tools will lead to efficient and safe installations.

Conclusion

Understanding 18-2 AWG wire equips you with the knowledge to make informed decisions for low-voltage electrical projects. Whether it’s for residential applications or commercial installations, this wire’s specifications, benefits, and potential limitations are crucial to consider. Always ensure you follow safety guidelines and installation practices to achieve reliable and safe electrical connections. Engaging with qualified professionals for complex installations is advisable, depending on your level of expertise.