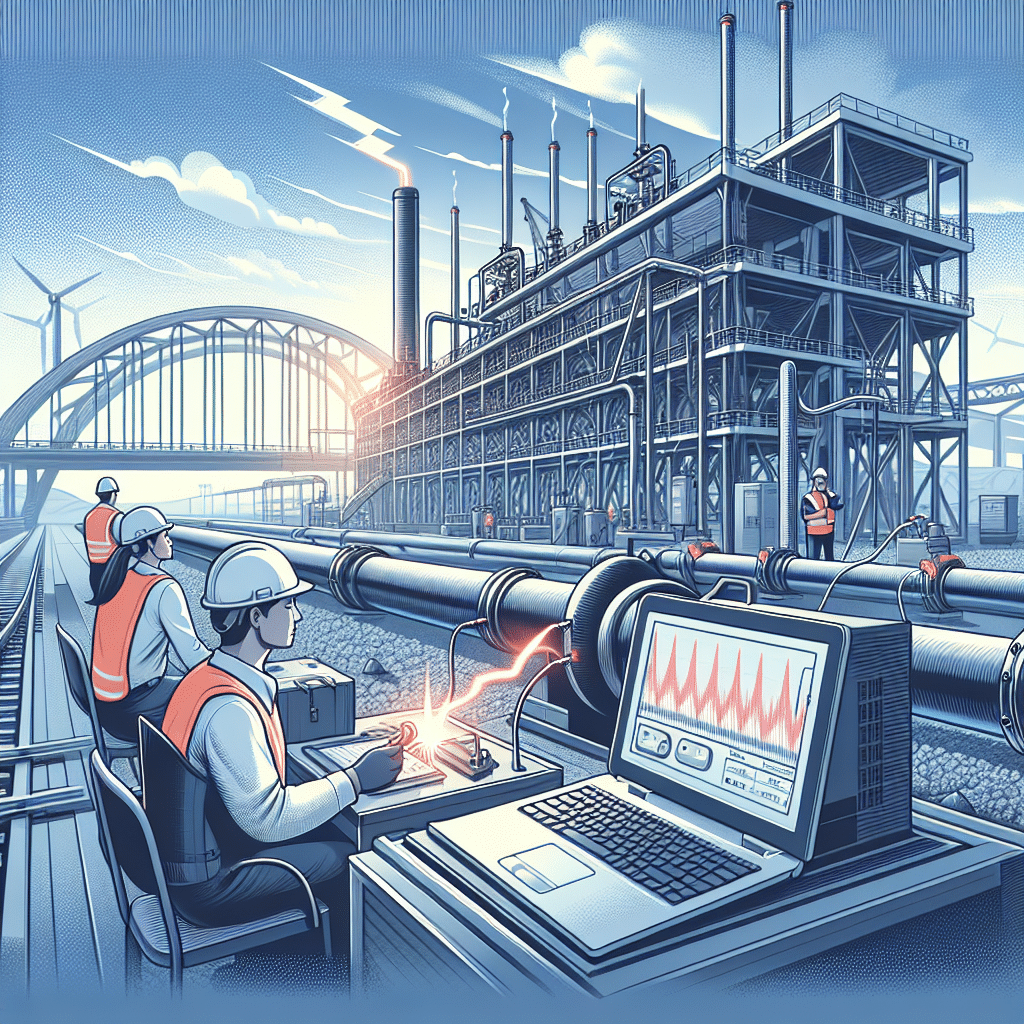

A cathodic IPS (Impressed Current Cathodic Protection) system is a method used to prevent corrosion on metal surfaces, particularly those submerged in water or buried underground. This system operates by applying a direct current to the surface of the metal, effectively making it the cathode of an electrochemical cell, thereby mitigating the corrosion process. It is widely employed in various industries, including pipelines, storage tanks, and marine vessels, to protect against the detrimental effects of electrolysis and environmental factors. The IPS system is designed to provide an adequate level of cathodic protection, ensuring the longevity and structural integrity of metal assets. With the right installation and maintenance, this system proves to be a vital investment in asset protection, reducing the risk of costly repairs and downtime.

Understanding the Cathodic IPS System

The cathodic IPS system is an essential component of corrosion management strategies for many industries. As steel and other metals are susceptible to corrosion, understanding how a cathodic protection system can prevent this degradation is crucial. Here’s a deeper look into its workings, components, and applications.

How Does Cathodic Protection Work?

Cathodic protection involves the principle of electrochemistry, where two metals are connected through a conductive medium. The metal susceptible to corrosion can be protected by transforming it into a cathode, while another anode (often made from aluminum, magnesium, or other metals) is installed nearby. The impressed current, generated by a DC power supply, drives electrons into the metal surface, counteracting the natural corrosion process.

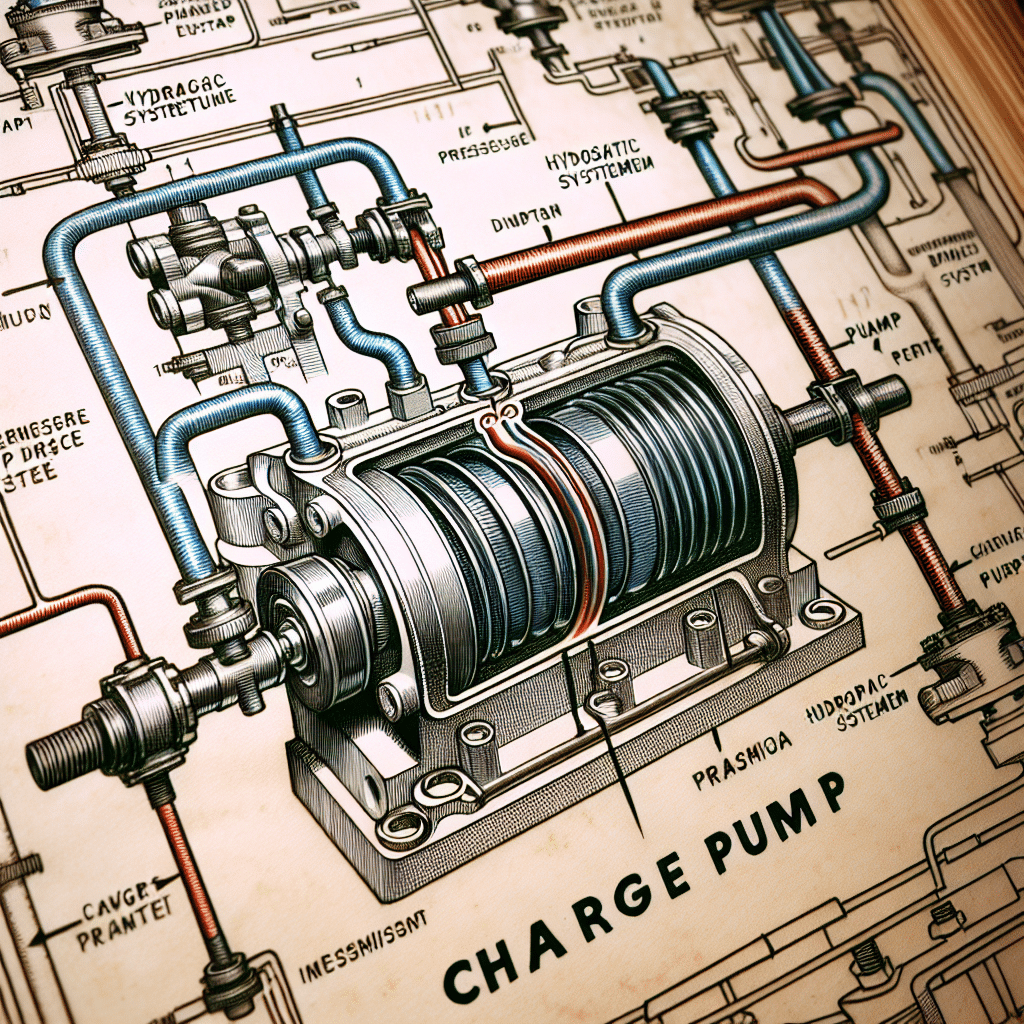

Components of a Cathodic IPS System

- Impressed Current Power Supply: Provides the necessary electrical current for the system.

- Inert Anodes: Made of materials like titanium or graphite, these anodes disperse electrical current over a wide area.

- Reference Electrode: Used to monitor the protection level and adjust the current output accordingly.

- Distributed Anode System: Often installed in grids or patterns around the area being protected.

- Control Equipment: Monitors and manages the cathodic protection system’s performance, ensuring adequate power supply.

Applications of Cathodic IPS Systems

Cathodic IPS systems are utilized in various applications where metal structures are prone to corrosion, including:

Pipelines

Oil and gas pipelines are critical infrastructures that commonly employ cathodic protection systems to maintain integrity over long lengths. Any failures can lead to catastrophic accidents and financial losses, making reliable protection paramount.

Storage Tanks

Above-ground and underground storage tanks storing hazardous materials benefit significantly from cathodic IPS systems. Regular monitoring and maintenance can mitigate corrosion and extend the lifespan of these structures.

Marine Structures

Ships, piers, and dock facilities operate in harsh environments where seawater accelerates corrosion. Impressed current systems are ideal for protecting these structures from significant repair costs and operational downtime.

Advantages of Using Cathodic IPS Systems

The implementation of a cathodic IPS system offers numerous advantages:

- Enhanced Protection: Provides comprehensive protection against corrosion for metal surfaces.

- Cost-Effectiveness: Reduces maintenance costs and the need for extensive repairs.

- Longer Lifespan: Extends the life of infrastructure, resulting in sustainable asset management.

- Flexible Designs: Can be tailored to suit various applications and specific environmental conditions.

Considerations and Limitations

While cathodic IPS systems are effective, several factors must be considered:

Installation and Maintenance Costs

Initial installation costs can be high, depending on the complexity of the system. Routine maintenance is essential to ensure its continued effectiveness, requiring a skilled workforce and regular inspections.

Environmental Factors

Cathodic protection systems can be influenced by soil resistivity and other environmental conditions. An understanding of these factors is critical during installation to optimize performance.

Overprotection Risks

If the impressed current is not regulated correctly, there is a risk of overprotection, leading to hydrogen embrittlement and damage to the metal structure. Proper monitoring tools and practices must be in place to avoid these pitfalls.

Frequently Asked Questions

What is the difference between cathodic protection and anode protection?

Cathodic protection makes use of an external power source to create a continuous flow of electrons to counteract corrosion. Anode protection, conversely, relies on sacrificial anodes which corrode instead of the protected metal, drawing corrosion away from it.

How often should a cathodic IPS system be inspected?

Typically, cathodic IPS systems should be inspected at least once a year, but more frequent checks may be warranted depending on the environmental conditions and specific applications.

Can cathodic protection be applied to concrete structures?

Yes, cathodic protection methods can be applied to reinforce concrete structures, primarily for rebar protection against corrosion due to de-icing salts and other environmental factors.

Is cathodic protection effective against all types of corrosion?

While cathodic protection is highly effective against galvanic corrosion and certain types of electrochemical corrosion, it may not be fully effective for all corrosion forms, such as those associated with microbiological activity.

Conclusion

A cathodic IPS system is an invaluable tool in corrosion prevention for various industries. By understanding its principles, components, and applications, you can effectively implement and manage a system that ensures the longevity and reliability of metal structures. Whether you’re involved in pipeline maintenance, storage facility management, or marine engineering, investing in a robust cathodic protection system can significantly mitigate risks, leading to safer and more sustainable operations.