Introduction

A charge pump in hydrostatic systems serves a pivotal role by transferring hydraulic fluid to various system components, ensuring optimal performance and efficiency. This device functions as a pressure-boosting mechanism, complementing hydraulic pumps by managing oil levels and supplying high pressure to actuators. By maintaining consistent fluid pressure, charge pumps can help prevent cavitation in hydraulic circuits, prolonging system life and enhancing operational stability. Additionally, charge pumps are crucial in applications where variable pressures are required, enabling deeper hydraulic drilling, versatile steering systems, and advanced automation in industrial machines. Understanding the significance of charge pumps in hydrostatic systems is essential for engineers and operators aiming to optimize hydraulic performance.

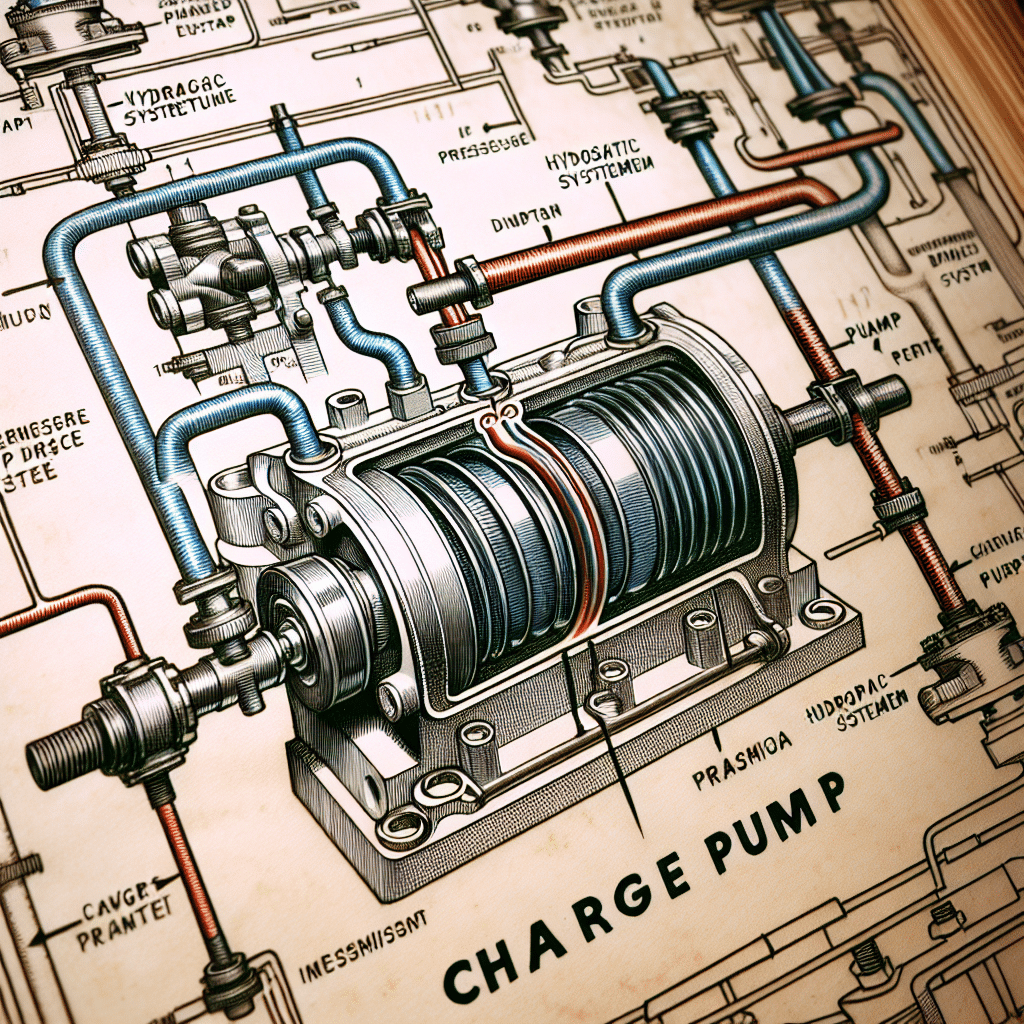

What is a Charge Pump?

A charge pump is a specific type of hydraulic pump designed to increase the pressure of hydraulic fluid before it is directed into the working circuits of a hydraulic system. Charge pumps have become essential in various industries, including construction, agriculture, and manufacturing, due to their ability to elevate fluid pressure while maintaining a relatively compact design.

How Charge Pumps Work in Hydrostatic Systems

In hydrostatic systems, charge pumps circulate hydraulic fluid, ensuring that there is always sufficient pressure available for the system to function effectively. They work by drawing fluid from the hydraulic reservoir and then compressing it to create a higher pressure output before delivering it to other pumps or actuators in the system.

Components of a Charge Pump

- Reservoir: Stores hydraulic fluid for pumping.

- Pump Housing: Encloses the internal components of the charge pump.

- Impeller or Gear Set: Creates the pressure increase within the pump.

- Inlet and Outlet Ports: Allow fluid to enter and exit the system.

- Check Valves: Prevent backflow, ensuring unidirectional fluid flow.

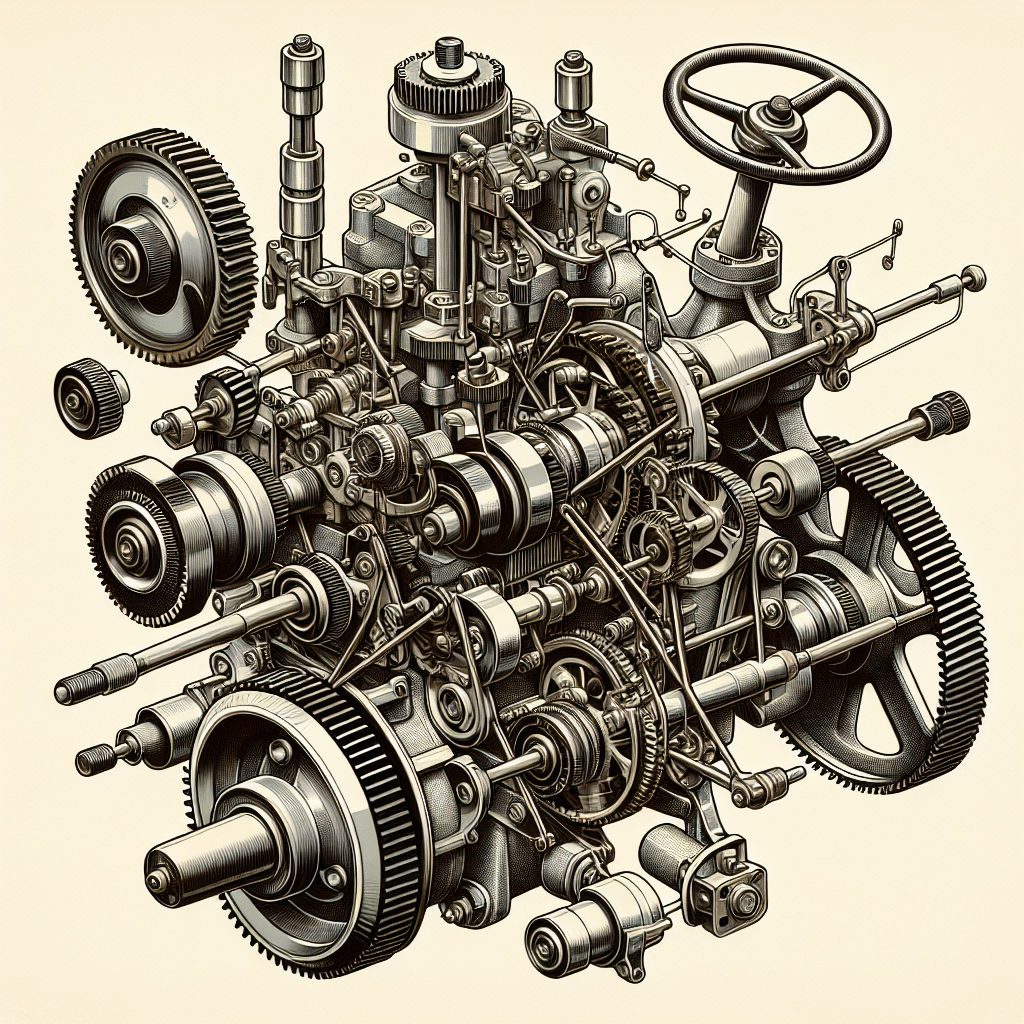

Types of Charge Pumps

There are primarily two types of charge pumps used in hydrostatic applications:

- Gear Charge Pumps: These utilize two or more gears rotating in opposite directions to create pressure. They are renowned for their durability and efficiency in high-pressure applications.

- Rotary Vane Charge Pumps: These pumps deploy movable vanes that slide in and out of a rotor, effectively changing the volume and pressure of the fluid. They are typically quieter and operate at lower viscosities.

The Importance of Charge Pumps in Hydrostatic Applications

Charge pumps play a crucial role in maintaining the efficiency and reliability of hydrostatic systems. Here are several reasons why they are indispensable:

1. Consistent Pressure Supply

Charge pumps ensure that hydraulic circuits receive a steady flow of pressurized fluid. This consistent pressure prevents issues such as cavitation and fluid starvation, enhancing system stability.

2. System Protection

The ability of charge pumps to manage pressure levels safeguards not only the charge pump itself but also other critical components of the hydraulic system. By preventing excess pressure, they mitigate the risk of hydraulic system failures.

3. Increased Efficiency

By supplying hydraulic fluids at optimal pressure levels, charge pumps contribute to overall system efficiency. This optimization, in turn, reduces energy consumption and enhances equipment performance.

Applications of Charge Pumps

Charge pumps find utility across a broad spectrum of applications:

1. Agriculture

In farming machinery, charge pumps help control functions such as steering and implement raising/lowering, delivering consistent fluid pressure to various hydraulic components.

2. Construction

Heavy equipment, like excavators and bulldozers, rely on charge pumps for maintaining hydraulic pressure to operate attachments and perform complex maneuvers.

3. Manufacturing Automation

In automated manufacturing systems, charge pumps are essential for pressurizing fluids used in robotics and material handling machinery.

Challenges and Considerations

While charge pumps are integral to hydrostatic systems, it’s important to heed certain challenges:

1. Temperature Sensitivity

Charge pumps can be affected by temperature changes, which may alter hydraulic fluid viscosity. It’s essential to choose the right hydraulic fluid and maintain temperature within recommended limits to prevent cavitation.

2. Wear and Tear

The internal components of charge pumps are subject to wear over time, which can lead to performance degradation. Regular maintenance, including inspections and fluid changes, is vital to ensure long service life.

3. Flow Rate Matching

For optimal performance, charge pumps must be correctly sized in relation to the system’s flow rate demands. A mismatched charge pump can lead to hydraulic inefficiencies or failure.

FAQs on Charge Pumps in Hydrostatic Systems

- What is the primary function of a charge pump in a hydrostatic system?

The main function of a charge pump is to maintain hydraulic pressure and supply fluid to other components within the system, enhancing performance and stability. - How do I know if my charge pump is functioning correctly?

Signs of a malfunctioning charge pump may include inconsistent hydraulic pressure, unusual noises, or hydraulic fluid leaks. Regular maintenance checks can help diagnose these issues early. - Can I replace my charge pump with any type of pump?

No, it’s crucial to select a replacement charge pump that matches the specifications and requirements of your specific hydraulic system to ensure optimal performance. - What maintenance does a charge pump require?

Routine checks should include monitoring fluid levels, replacing hydraulic fluids periodically, and inspecting the pump for signs of wear or damage.

Conclusion

Understanding the function and importance of charge pumps in hydrostatic systems is essential for operators and engineers aiming to optimize equipment performance. By ensuring adequate hydraulic pressure and preventing potential failures, charge pumps not only enhance overall system efficiency but also extend the service life of hydraulic equipment. Through proper selection, maintenance, and operation of charge pumps, you can significantly improve the performance and reliability of your hydraulic systems.