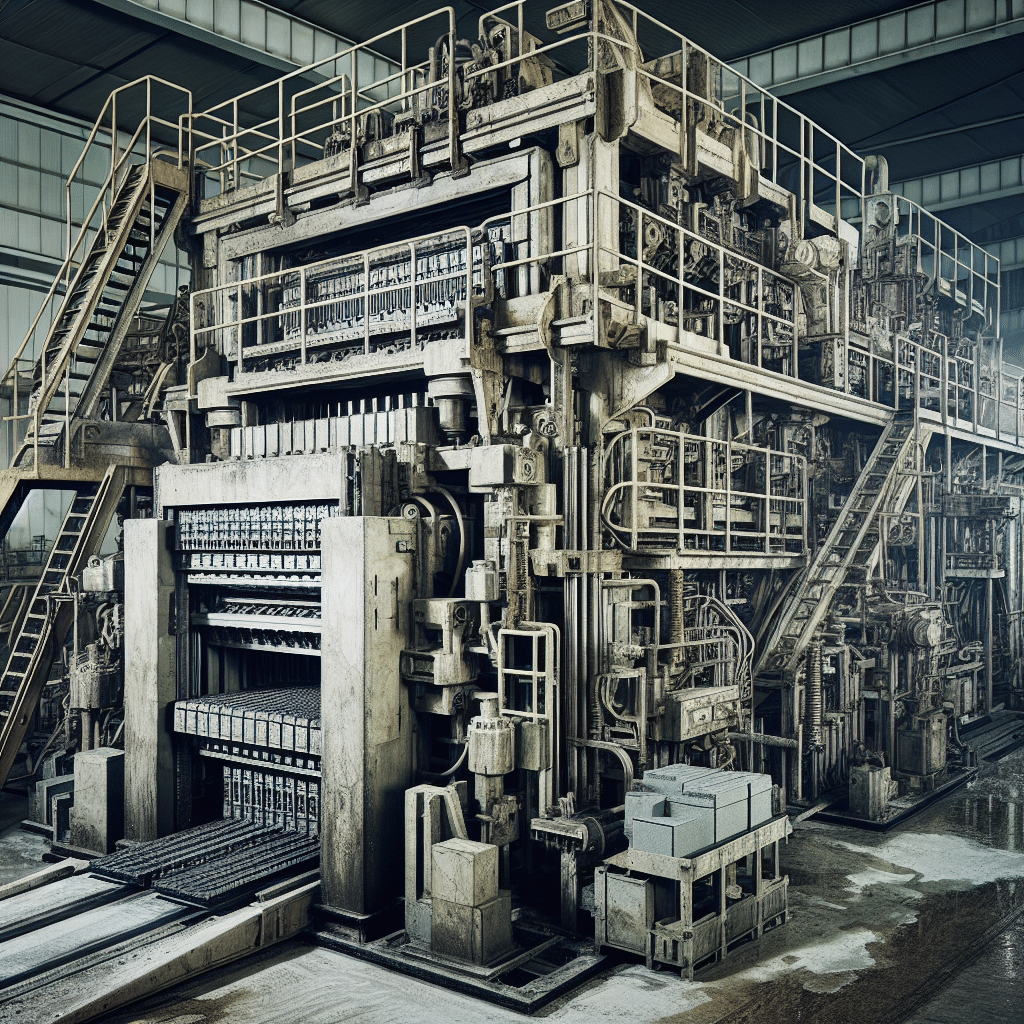

A concrete block machine is an industrial equipment specifically designed for the production of concrete blocks, which are essential components in construction. These machines automate the process of forming concrete blocks from a mixture of cement, water, aggregates, and additives. They come in various types, including manual, semi-automatic, and fully automatic machines, catering to different production capacities and operational complexities. The primary function of a concrete block machine is to mix raw materials, mold the mixture into blocks, and then cure the blocks to achieve the desired strength and durability. Concrete block machines contribute significantly to the efficiency and cost-effectiveness of construction projects, making them vital in both commercial and residential building endeavors.

Introduction to Concrete Block Machines

Concrete block machines play a pivotal role in modern construction, providing the essential capability to fabricate concrete blocks efficiently. These machines enable the production of standard or customized block sizes, ensuring versatility for various architectural needs. From small-scale builders to large-scale construction firms, understanding the types, functionalities, and operational efficiencies of concrete block machines is crucial for maximizing productivity and meeting project demands.

Types of Concrete Block Machines

Concrete block machines come in several varieties, each tailored to different production techniques and scales of operation. Here are the primary types:

1. Manual Concrete Block Machines

Manual machines require operators to perform most tasks, from mixing concrete to the actual block formation. These machines are ideal for small operations with lower production needs. They are cost-effective, relatively simple to operate, and do not require advanced technical knowledge.

2. Semi-Automatic Concrete Block Machines

These machines combine manual processes with automated features. This type allows for greater efficiency compared to manual machines, as certain functions like block demolding or mixing may be automated. Semi-automatic machines are suited for medium-scale operations, providing a balance between cost and output.

3. Fully Automatic Concrete Block Machines

Fully automatic block machines are designed for high-volume production with minimal manual intervention. These machines can automatically mix, mold, and cure blocks, significantly reducing labor costs and increasing efficiency. They are ideal for large construction companies that require a steady supply of concrete blocks.

How Concrete Block Machines Work

Understanding the operational mechanism of concrete block machines is vital for optimizing their use. The process can generally be divided into several key steps:

1. Material Preparation

The first step in block production involves gathering and preparing the raw materials: cement, aggregates (sand, gravel, or crushed stone), and water. For some applications, additives may also be introduced to enhance certain properties of the concrete mix.

2. Mixing

Next, the materials are combined in a mixer, where they undergo a thorough mixing process to ensure uniform consistency. The water-to-cement ratio is crucial at this stage to achieve the desired strength and workability of the concrete.

3. Molding

The mixed concrete is then poured into molds, which define the shape and size of the blocks. This is typically done using vibration or hydraulic pressure to ensure that the concrete fills the mold completely and reduces any trapped air.

4. Curing

Once formed, the blocks must be cured to achieve the necessary strength. Curing can be done using moisture control techniques or heat application, depending on the machine’s capabilities and the desired specifications of the blocks.

5. Quality Control

The final step involves quality inspections to ensure that the blocks meet industry standards, including compressive strength, durability, and aesthetic quality. Quality control is crucial to avoid defects that could compromise structural integrity.

Advantages of Using Concrete Block Machines

Investing in a concrete block machine presents several advantages for construction companies and builders:

1. Cost-Efficiency

By automating the block production process, businesses can significantly reduce labor costs and increase output, leading to higher profitability.

2. Customization

Machines can produce a variety of block sizes and shapes, allowing builders to customize their products based on project specifications.

3. Consistency and Quality

Automated machines provide uniformity in block production, ensuring high quality and reducing variations that can occur with manual processes.

4. Speed

With increased automation, the speed of block production is significantly enhanced, enabling builders to meet tight deadlines.

Considerations for Choosing a Concrete Block Machine

When selecting a concrete block machine, several factors should be taken into account:

1. Production Needs

Evaluate the volume of blocks you need to produce daily or weekly. This will guide you in selecting between manual, semi-automatic, or fully automatic options.

2. Type of Blocks

Consider the types of blocks required for your projects—standard, hollow, or interlocking blocks—and ensure the machine can accommodate these specifications.

3. Budget

Your budget will significantly influence the choice of machine. While fully automatic machines provide high efficiency, they also represent a larger capital investment.

4. Space and Layout

Assess the available space in your production facility to ensure that the machine will fit well and accommodate necessary workflows.

5. After-Sales Support and Maintenance

Choosing a reliable manufacturer with good customer service and support can make a big difference in machine maintenance and operational uptime.

Future Trends in Concrete Block Manufacturing

The concrete block manufacturing industry is evolving, influenced by technological advancements and sustainability trends:

1. Automation and IoT Integration

The integration of smart technologies and Internet of Things (IoT) capabilities is expected to improve monitoring and control in concrete block production.

2. Sustainable Practices

Increasing demand for environmentally friendly building materials has led manufacturers to explore alternatives, such as recycled materials, for producing concrete blocks.

3. Advanced Curing Techniques

Innovations in curing technologies, such as rapid curing and self-curing concrete, could enhance production speed and block durability.

4. Customization through 3D Printing

The rise of 3D printing technology may enable the production of concrete elements with complex geometries that traditional machines cannot achieve.

Frequently Asked Questions (FAQ)

1. What materials are needed for a concrete block machine?

A concrete block machine typically requires cement, aggregates (sand, gravel), water, and optionally, additives to achieve specific properties in the concrete.

2. How much does a concrete block machine cost?

The price of a concrete block machine can vary widely based on the type and automation level, ranging from a few thousand dollars for manual machines to several hundred thousand for fully automatic systems.

3. How long do concrete blocks take to cure?

The curing time for concrete blocks can vary depending on several factors, but it generally takes about 7 to 14 days to achieve optimal strength, depending on environmental conditions and material properties.

4. Can concrete block machines produce different shapes and sizes?

Yes, modern concrete block machines can be customized to produce a wide range of block shapes and sizes, including standard and specialty blocks, according to project requirements.

5. What is the lifespan of concrete block machines?

The lifespan of a concrete block machine depends on usage, maintenance, and the quality of the machine itself, but well-maintained machines can last for several decades.

Conclusion

In conclusion, understanding what a concrete block machine is and how it operates can significantly enhance production capacity and efficiency in the construction industry. As the demand for concrete blocks continues to grow, investing in the right type of block machine will prove beneficial for construction businesses striving to meet market needs effectively. By being aware of the different types available, their functionalities, advantages, and future trends, you can make an informed decision that aligns with your operational goals and maximizes your investment.