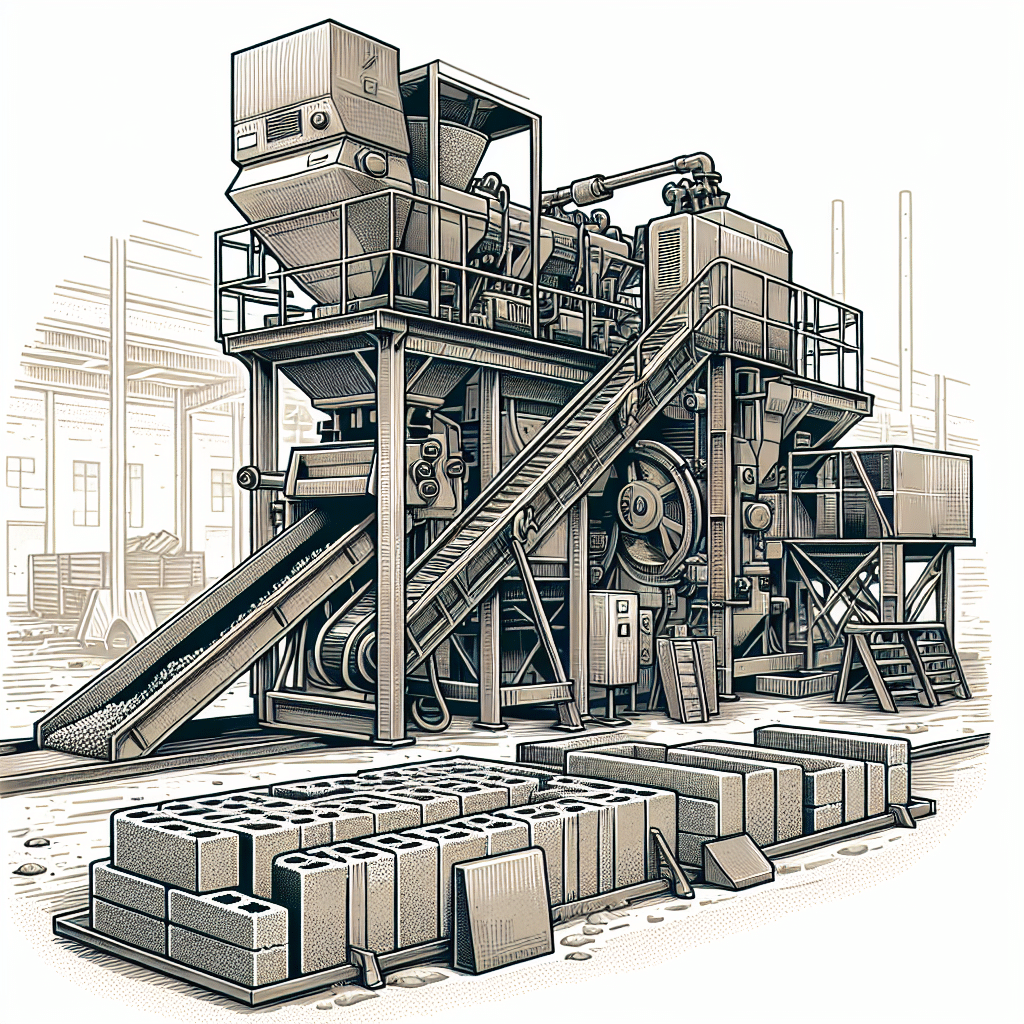

What is a concrete block making machine? A concrete block making machine is a sophisticated equipment designed for the production of concrete blocks in various sizes and shapes. These machines operate through automated or semi-automated processes, utilizing a mixture of cement, water, and aggregates to create durable and versatile building materials. The core function of this equipment is to compress and mold the concrete mixture into blocks which can then be cured and used in construction projects, such as walls, pavements, and foundations. With advancements in technology, modern concrete block making machines offer improved efficiency, better energy consumption, and enhanced output quality, making them essential in the concrete manufacturing industry.

1. Understanding Concrete Block Making Machines

Concrete block making machines have evolved significantly over the years, enhancing their capabilities and efficiency. These machines typically consist of several components, including a mixer, a molding unit, a hydraulic system, and a control panel. Key types of machines vary based on their mode of operation and the production scale they accommodate.

2. Types of Concrete Block Making Machines

Concrete block making machines can be categorized into several types:

- Manual Block Making Machines: These are basic machines requiring manual labor to operate. They are suitable for small-scale production and are often used in developing regions.

- Semi-Automatic Block Making Machines: They incorporate automated features but still require some manual input. These machines usually consist of a conveyor belt and require less labor compared to manual options.

- Fully Automatic Block Making Machines: These advanced systems can produce concrete blocks with minimal human intervention. They feature sophisticated control systems and usually offer the highest production capabilities.

- Mobile Block Making Machines: Portable and versatile, these machines can be easily transported to different sites, making them an ideal option for businesses needing flexibility.

3. Key Components of Concrete Block Making Machines

The effectiveness of a concrete block making machine largely relies on its components:

- Mixing Unit: This component ensures that the concrete mixture is homogeneous, incorporating cement, aggregates, and water efficiently.

- Molding Unit: The mold shapes the mixture into either standard block sizes or custom designs as per project requirements.

- Hydraulic System: It provides the necessary pressure to compress the concrete within the mold, ensuring high-density blocks.

- Control Panel: Modern machines are equipped with digital control panels, allowing operators to monitor and adjust settings for optimal performance.

4. The Block Making Process

4.1 Material Preparation

The process begins with the careful selection and preparation of raw materials: cement, aggregates (sand, gravel), and water. Quality control at this stage is crucial, as the properties of these materials significantly influence the final product’s strength.

4.2 Mixing

After preparation, the materials are fed into the mixing unit, where they are blended until a uniform consistency is achieved. Achieving the right water-cement ratio is vital to ensure durability and strength in the final concrete blocks.

4.3 Molding

The homogeneous mixture is then transferred to the molding unit. The hydraulic system compresses the mixture into molds of predefined shapes and sizes. Depending on the machine’s setup, multiple blocks can be formed simultaneously, increasing production efficiency.

4.4 Curing

Following molding, the blocks undergo a curing process. This typically occurs in a steam chamber or through air curing, allowing chemical reactions to strengthen the blocks further. Proper curing is essential to enhance the compressive strength and overall integrity of the blocks.

5. Advantages of Using Concrete Block Making Machines

Investing in concrete block making machines holds several advantages:

- Efficiency: Automation and improved technology in these machines lead to faster production rates, which can significantly reduce labor costs.

- Quality Control: Consistent mixing and molding processes enable the production of uniform blocks, which are crucial for structural integrity.

- Customizable Output: Many machines allow for custom molds, enabling the production of unique block shapes and sizes tailored to specific project needs.

- Cost-Effectiveness: Over time, the reduced labor costs combined with enhanced production efficiency can lead to significant savings.

6. Addressing Concerns and Limitations

While concrete block making machines offer substantial benefits, there are considerations to keep in mind:

- Initial Investment: The upfront costs of high-quality block making machines can be considerable, posing a challenge for small businesses.

- Maintenance Requirements: Regular maintenance is crucial to ensure the longevity and performance of the machines.

- Skilled Operation: While some machines are user-friendly, complex operations may require trained professionals to maximize production efficiency.

7. FAQs about Concrete Block Making Machines

7.1 What types of blocks can be made with a concrete block machine?

A concrete block making machine can produce a variety of block types, including standard concrete blocks, hollow blocks, interlocking blocks, and decorative blocks, depending on the molds used.

7.2 What is the average output of a concrete block making machine?

The output varies by machine type and capacity but can range from a few hundred to several thousand blocks per day, based on automation levels and production settings.

7.3 How much does a concrete block making machine cost?

The cost can vary widely based on the type and capacity of the machine, ranging from a few thousand dollars for manual machines to over $100,000 for fully automatic systems.

7.4 What maintenance is required for concrete block making machines?

Regular maintenance includes cleaning, lubricating moving parts, checking for wear and tear, and ensuring the hydraulic system is functioning correctly to maintain optimal production quality.

8. Conclusion

In summary, concrete block making machines play a crucial role in modern construction, streamlining the production of durable building materials. Their ability to produce high-quality blocks with efficiency and consistency makes them invaluable for both large-scale projects and local construction ventures. Despite some initial costs and maintenance needs, their long-term benefits solidify their status as essential tools in the industry.