Diesel PM (Particulate Matter) sensors are advanced devices designed to monitor and measure the concentration of particulate matter emissions from diesel engines. These sensors play a crucial role in ensuring compliance with environmental regulations and maintaining optimal engine performance. By accurately detecting PM levels, they help in diagnosing engine issues, optimizing fuel efficiency, and minimizing harmful emissions. This technology is essential in various industries where diesel engines are prevalent, including transportation, construction, and agriculture. Understanding the function and importance of diesel PM sensors is vital for operators and maintenance personnel seeking to enhance the efficiency and eco-friendliness of diesel-powered equipment.

Understanding Diesel PM Sensors

Diesel PM sensors are integral to modern diesel engine emission control systems. They monitor the quantity and composition of particulate matter emitted through the exhaust system, providing real-time data that can help in effective decision-making regarding maintenance and operation. These sensors typically employ advanced detection techniques such as laser or optical methods to ensure accurate measurements.

1. How Diesel PM Sensors Work

At its core, a diesel PM sensor operates by analyzing the exhaust gases emitted from diesel engines. When exhaust passes through the sensor, light from a laser or LED illuminates the particulate matter present. The light scatters upon contacting particles, and the sensor detects the changes in the intensity and wavelength of the light. The collected data is processed and translated into a readable output, indicating the concentration of PM in the exhaust stream.

2. Importance of Diesel PM Sensors

The role of diesel PM sensors extends beyond just measurement. Here are some key aspects emphasizing their importance:

- Environmental Compliance: With stringent regulations imposed by environmental agencies like the EPA (Environmental Protection Agency) in the United States, diesel PM sensors are critical for monitoring emissions and ensuring compliance.

- Engine Performance: By providing insights into particulate emissions, these sensors enable operators to fine-tune engine parameters, leading to better performance and longevity.

- Fuel Efficiency: Monitoring particulate matter allows for adjustments in fuel injection and combustion processes, ultimately optimizing fuel consumption.

- Diagnostic Function: The sensors can help in identifying potential issues within the engine’s exhaust system, aiding in timely maintenance and repairs.

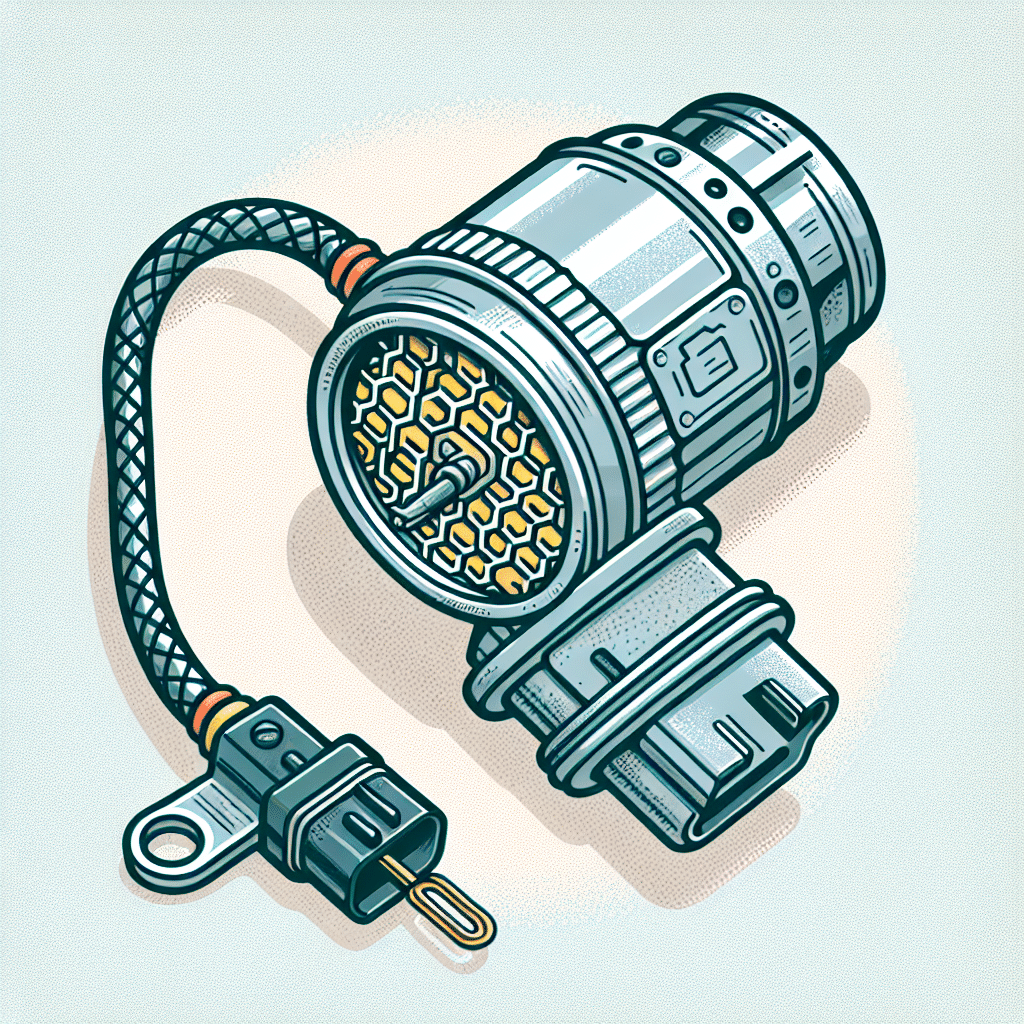

3. Components of Diesel PM Sensors

A typical diesel PM sensor consists of several key components:

- Detection Mechanism: This may involve a laser or electrochemical sensor that detects particulate matter concentration.

- Signal Processing Unit: Responsible for interpreting the data collected and converting it into usable information.

- Communication Interface: Allows the sensor to communicate with the vehicle’s onboard diagnostics system or an external monitoring system.

4. Types of Diesel PM Sensors

There are various types of diesel PM sensors, each designed for specific applications and technologies:

- Optical PM Sensors: Utilize laser technology for precise measurements of particulate emissions.

- Electrochemical Sensors: Employ chemical reactions to detect particulates and measure their concentration.

- Capacitive Sensors: Measure changes in capacitance caused by the accumulation of particulate matter.

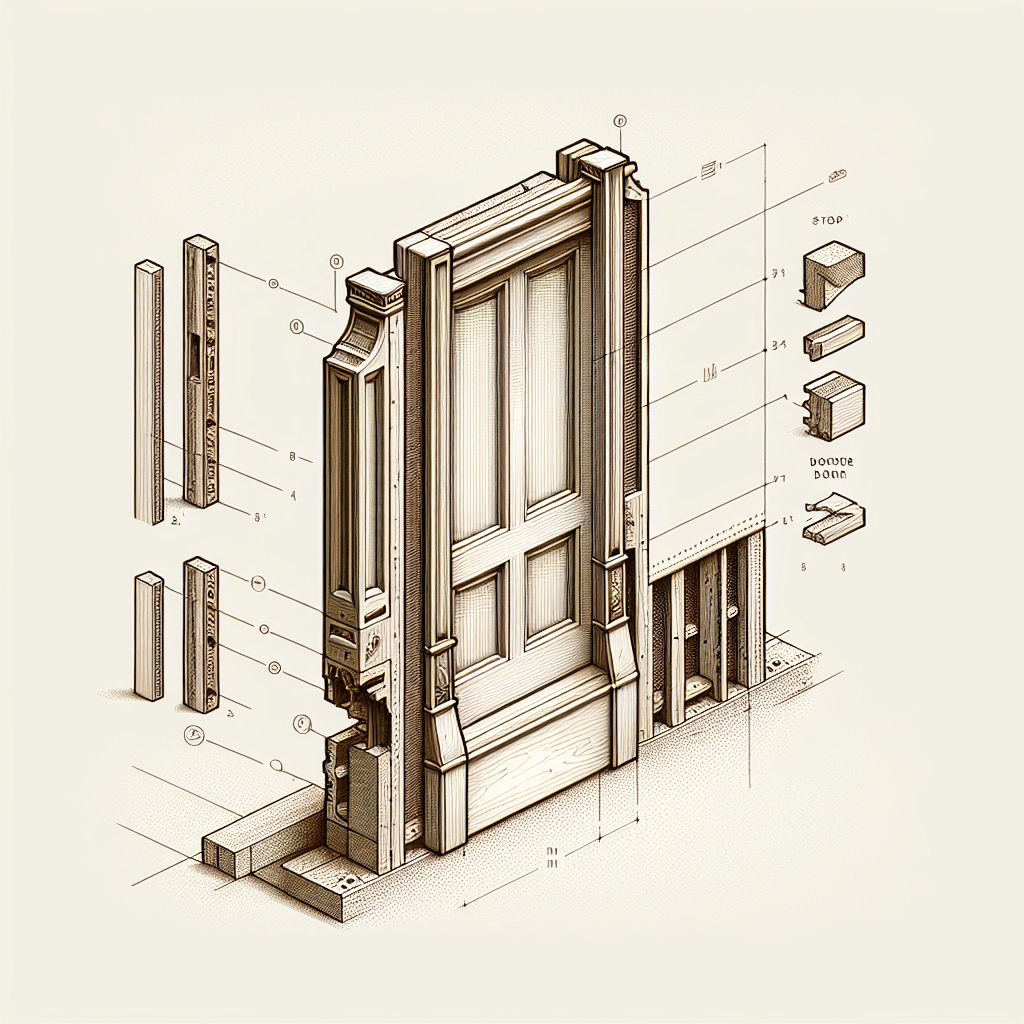

Installation and Maintenance of Diesel PM Sensors

Proper installation and maintenance of diesel PM sensors are crucial for their accurate functionality. Here are some best practices:

- Installation: Ensure that the sensor is correctly aligned and placed within the exhaust system according to manufacturer specifications.

- Calibration: Regular calibration is essential to maintain accuracy over time. Follow the manufacturer’s guidelines for calibration intervals.

- Cleaning: Periodic cleaning may be necessary to prevent buildup that can obstruct readings.

- Inspection: Regular inspections can help in identifying wear or damage that may affect sensor performance.

Challenges and Counterarguments

Despite their advantages, diesel PM sensors are not without challenges. Some common concerns include:

- Cost: Initial acquisition and installation costs can be high for some establishments, leading to reluctance in adoption.

- Maintenance Needs: Continuous monitoring requires maintenance efforts, which may strain resources.

- Interference from Other Particulates: Sensors can sometimes be influenced by various other particulate types, leading to inaccurate readings under certain conditions.

Nevertheless, the benefits of employing diesel PM sensors typically outweigh these challenges, particularly in regulated industries that prioritize environmental impact and operational efficiencies. It’s vital to weigh the pros and cons based on your specific operational context and regulatory requirements.

Advantages of Using Diesel PM Sensors

Utilizing diesel PM sensors provides several significant advantages:

- Enhanced Environmental Protection: By monitoring and minimizing particulate emissions, these sensors contribute to better air quality.

- Improved Engine Health: Continuous monitoring allows for early detection of potential problems, reducing repair costs and downtime.

- Long-Term Cost Savings: While the upfront investment may be substantial, the savings achieved through improved efficiency and reduced fines can outweigh initial expenses.

Future Trends in Diesel PM Sensor Technology

The future of diesel PM sensors is promising, with continual advancements anticipated in the following areas:

- Integration with IoT: As the Internet of Things (IoT) expands, PM sensors will likely incorporate smart technology for data sharing and remote monitoring.

- Enhanced Sensitivity: Upcoming models may feature improved sensitivity, allowing for detection of even lower concentrations of particulate matter.

- Renewable Solutions: There’s potential for developing sensors that utilize renewable energy sources, further reducing environmental impact.

Frequently Asked Questions (FAQ)

What are the typical applications of diesel PM sensors?

Diesel PM sensors find applications in various industries, including transportation (trucks and buses), construction, agriculture, and marine. They are used in any setting where diesel engines are present and emissions need to be monitored.

How do I know if my diesel PM sensor needs replacement?

Indications that a diesel PM sensor may need replacement include inconsistent readings, warning lights on the dashboard, reduced engine performance, or increased emissions. Regular diagnostics can help in early identification.

Are diesel PM sensors legally required?

In the United States, diesel PM sensors are often legally required for compliance with emissions regulations, particularly for heavy-duty vehicles. Always check local and federal regulations to ensure adherence to specific requirements.

Can diesel PM sensors be retrofitted to older diesel engines?

Yes, many diesel PM sensors can be retrofitted to older engines, provided they meet compatibility requirements. Consulting with a qualified technician or manufacturer can provide guidance on suitable sensors for specific applications.

What maintenance is recommended for diesel PM sensors?

Regular maintenance includes periodic calibration, cleaning to prevent buildup, inspection for any potential damage, and ensuring proper alignment within the exhaust system. Following manufacturer guidelines is crucial for optimal operation.

Conclusion

Diesel PM sensors represent a pivotal technology in managing diesel emissions, contributing significantly to regulatory compliance, environmental sustainability, and enhanced engine performance. By considering the installation, maintenance, and future trends of these sensors, stakeholders can achieve a more efficient and cleaner operation in diesel-powered systems. Whether you are involved in transportation, construction, or another sector reliant on diesel engines, understanding and employing diesel PM sensors can bring substantial benefits both for your operations and the environment.