Introduction

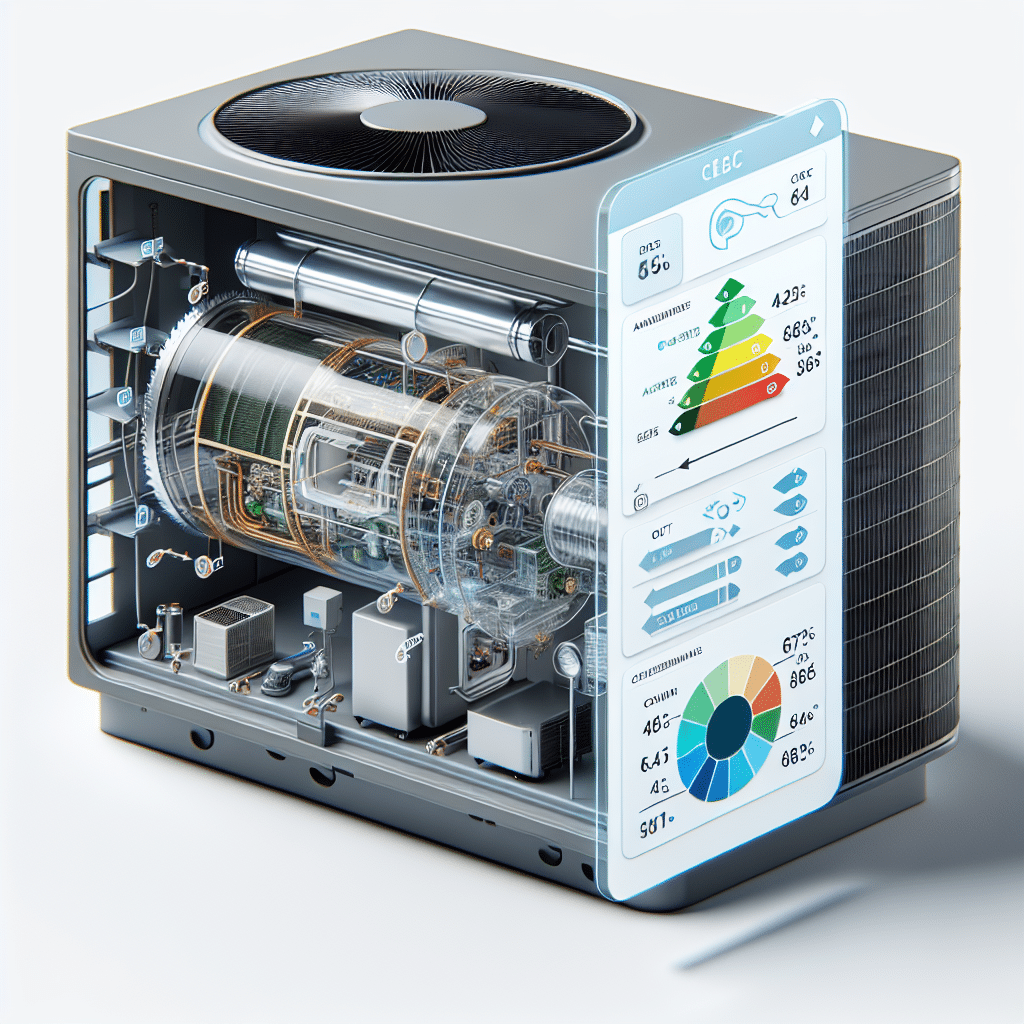

A heat versiser is a specialized device used in thermal management systems to ensure efficient heat transfer and temperature regulation. Typically used in industrial processes, HVAC (heating, ventilation, and air conditioning) applications, and certain electronic devices, the heat versiser can either add or subtract heat from a system depending on the operational demands. By effectively managing thermal energy, heat versisers contribute to system efficiency, safety, and longevity, making them critical components in modern technology. Understanding the definition and function of a heat versiser is vital for engineers, designers, and technicians involved in fields where temperature control and energy management are paramount.

Understanding the Heat Versiser

1. Definition and Function

The term “heat versiser” refers to a system capable of either heating or cooling a substance, adapting its operation based on specific needs. It functions by utilizing principles of thermodynamics to transfer heat energy effectively. Generally, heat versisers are equipped with mechanisms such as heat exchangers, condensers, and evaporators, enabling them to operate in various thermal conditions.

2. Types of Heat Versisers

Heat versisers can be categorized based on their applications:

- Industrial Heat Versisers: Often used in manufacturing processes that require precise temperature control such as chemical processing and materials manufacturing.

- HVAC Heat Versisers: Used in heating and cooling systems in residential and commercial buildings to maintain optimal indoor temperatures.

- Electronic Heat Versisers: Incorporated into consumer electronics to prevent overheating and enhance operational reliability.

3. How Heat Versisers Work

Heat versisers leverage various technologies to transfer heat. Common methods include:

- Heat Pumps: Operate by extracting heat from one environment and transferring it to another, effectively functioning as both heaters and coolers.

- Heat Exchangers: Transfer heat between two or more fluids without mixing them, maximizing heat exchange efficiency.

- Phase Change Materials (PCMs): Absorb or release latent heat during phase transitions, allowing for significant thermal energy management.

4. Applications of Heat Versisers

Heat versisers have diverse applications across various sectors:

- Residential Heating and Cooling: Used in smart home systems to provide energy-efficient temperature control.

- Industrial Processes: Essential in applications that involve exothermic or endothermic reactions, where precise heat control is critical.

- Aerospace and Automotive: Help maintain optimal operating temperatures of engines and electronic components, enhancing safety and efficiency.

5. Advantages of Implementing Heat Versisers

Integrating a heat versiser into a system can yield multiple benefits:

- Enhanced Energy Efficiency: By optimizing heat transfer, they reduce energy consumption, leading to lower operational costs.

- Improved System Lifespan: Effective temperature regulation prevents overheating, thereby prolonging the life of equipment.

- Environmental Benefits: Reduced energy use translates into a smaller carbon footprint, supporting corporate sustainability goals.

6. Challenges and Considerations

Despite their advantages, there are challenges associated with heat versisers:

- Initial Investment Costs: The implementation of sophisticated heat versisers can be capital-intensive, requiring a careful cost-benefit analysis.

- Maintenance Needs: Regular servicing is essential to ensure optimal performance and prevent system failures.

- Technological Complexity: Designing an effective heat versiser system requires expertise in thermodynamics and engineering principles.

FAQs About Heat Versisers

What is the main purpose of a heat versiser?

The main purpose of a heat versiser is to manage thermal energy, either by heating or cooling a system according to operational requirements, thereby improving efficiency and extending the equipment’s lifespan.

In which industries are heat versisers commonly used?

Heat versisers are commonly utilized in various sectors including HVAC, industrial manufacturing, aerospace, automotive, electronics, and renewable energy systems.

How do heat versisers contribute to energy efficiency?

By optimizing heat transfer and maintaining desired temperatures, heat versisers help reduce energy consumption, leading to lower operational costs and diminished environmental impact.

Are heat versisers easy to maintain?

While they require some ongoing maintenance, such as regular inspections and servicing, proper care can ensure they operate efficiently and effectively over time.

What factors should be considered when selecting a heat versiser?

Key factors include the operational requirements, capacity, efficiency rating, initial cost, maintenance needs, and specific application demands.