Introduction

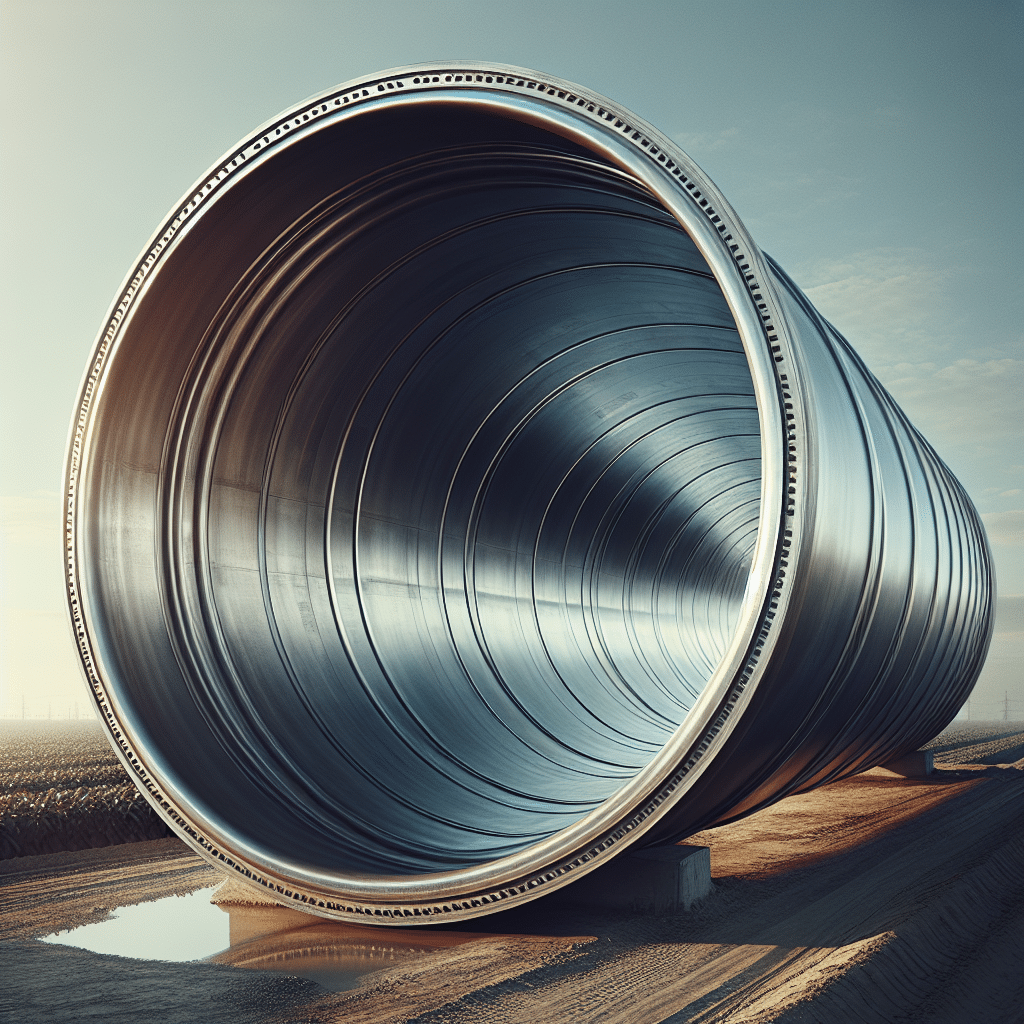

A large steel irrigation pipe is commonly known as a steel irrigation main or steel distribution pipe. These robust pipes are integral to agricultural irrigation systems, efficiently transporting water to fields and crops. Steel irrigation pipes are favored for their strength and durability, which makes them well-suited for handling high-pressure environments and harsh outdoor conditions. Usually available in various diameters, these pipes can be made from either carbon steel or galvanized steel, depending on the specific requirements of the irrigation system. Their design and construction can enhance water delivery efficiency, reduce leaks, and withstand physical stresses that would compromise more fragile materials.

Understanding Steel Irrigation Pipes

1. Types of Steel Irrigation Pipes

Steel irrigation pipes can be classified based on their material composition and structural specifications. The most common types include:

- Carbon Steel Pipes: Made primarily from carbon and iron, these pipes offer excellent tensile strength and are highly durable. They are generally uncoated, which makes them prone to corrosion unless protected with a suitable lining or coating.

- Galvanized Steel Pipes: These pipes are coated with zinc to prevent rust and corrosion, making them more suitable for outdoor applications. The galvanization process extends their lifespan, reducing maintenance costs.

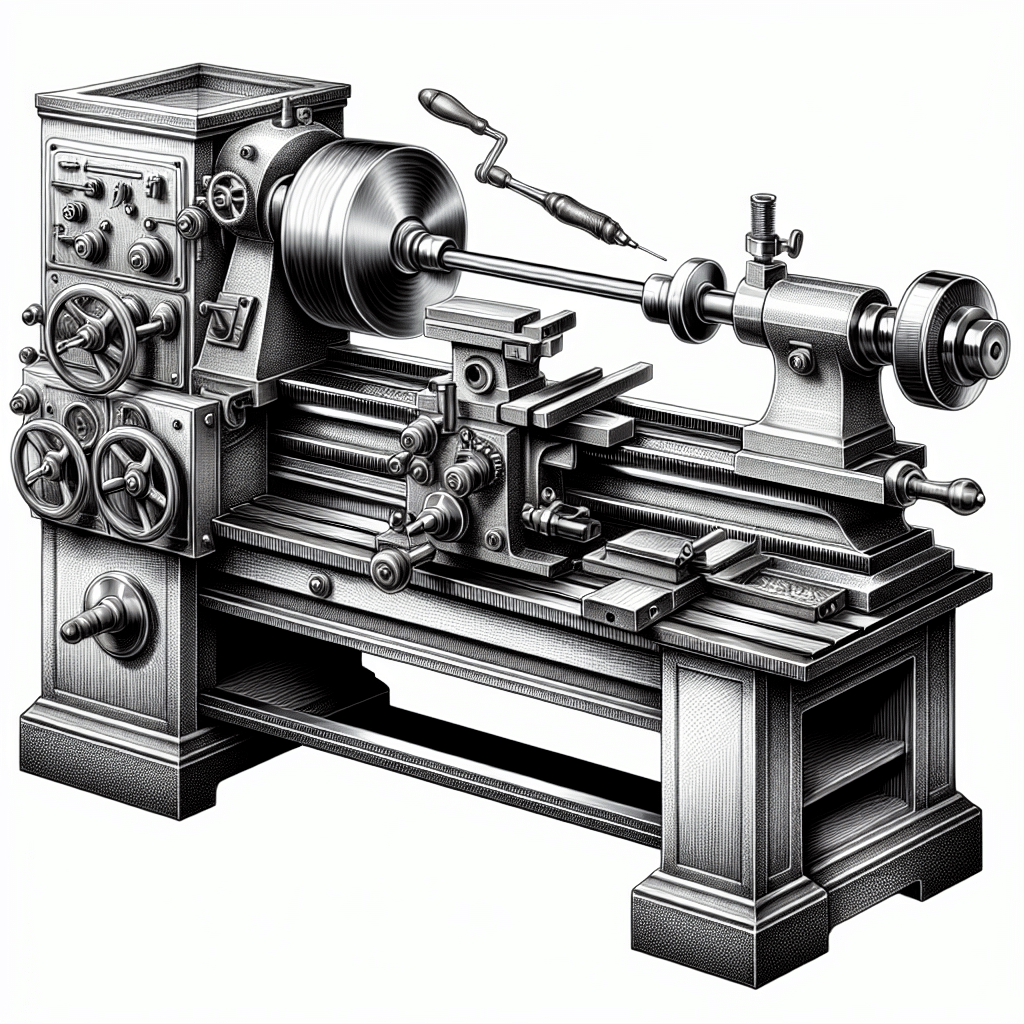

- Welded Steel Pipes: Created by welding steel plates together, these pipes can be custom-made in terms of length and diameter, offering flexibility in design.

2. Applications in Agriculture

Steel irrigation pipes play a crucial role in agriculture, especially in regions where water scarcity is an issue. Key applications include:

- Mainlines: These large-diameter pipes transport water from the source (like a river or reservoir) to various points in the agricultural field.

- Submains: Smaller than mainlines, submains distribute water to different irrigation zones within a field.

- Laterals: These pipes extend to the specific area of the crop, delivering water directly to field rows.

3. Advantages of Using Steel Pipes

Choosing steel pipes for irrigation systems presents several advantages:

- Durability: Steel can withstand exposure to the elements and physical stresses, making it ideal for long-term installations.

- High Pressure Tolerance: Steel irrigation pipes can handle high-pressure water flows, ensuring efficient water distribution across the fields.

- Cost-Effectiveness: Although the initial investment might be higher, their longevity minimizes replacement and maintenance costs, thus providing long-term savings.

Installation and Maintenance

1. Installation Process

Proper installation is critical to ensure the functionality of steel irrigation pipes. The installation process typically involves:

- Site Assessment: Evaluating soil conditions, landscape, and existing water sources.

- Pipe Trenching: Digging trenches to accommodate the pipes, ensuring they are at the correct depth to prevent freezing and damage.

- Joining Pipes: Using fittings, flanges, or welds to connect different lengths of pipes securely.

- Backfilling: Once installed, the trenches are backfilled with soil, compacted adequately to prevent settling.

2. Maintenance Practices

Regular maintenance ensures the longevity and efficiency of steel irrigation systems. Recommended practices include:

- Visual Inspections: Regularly check for corrosion, leaks, and physical damage.

- Flushing the System: Periodically flush the system to remove any sediment build-up that can obstruct water flow.

- Corrosion Monitoring: Apply protective coatings or cathodic protection systems, especially if using carbon steel pipes.

Environmental and Economic Considerations

1. Environmental Impact

The use of steel irrigation pipes can have both positive and negative environmental impacts:

- Positive: Efficient water distribution helps conserve water, reducing waste in areas of scarcity.

- Negative: Extraction of natural resources for steel production can contribute to environmental degradation.

2. Economic Factors

Investing in steel irrigation systems can boost agricultural productivity, directly impacting local economies:

- Increased Crop Yields: Efficient water delivery can lead to healthier crops and increased yields.

- Job Creation: Installation and maintenance of irrigation systems create job opportunities in local communities.

Comparing Steel Pipes with Other Materials

1. PVC and Other Plastic Pipes

While PVC and other plastic pipes are lighter and easier to install, they lack the structural strength and pressure tolerance of steel. However, they are resistant to corrosion and are often cheaper upfront. The choice between materials depends on specific irrigation requirements and budget constraints.

2. Ductile Iron Pipes

Ductile iron pipes, like steel, are strong and durable. They offer excellent pressure-handling capabilities but can be heavier and more expensive than both steel and PVC alternatives. The choice will hinge on factors like the distances involved and the specific conditions of the installation site.

Frequently Asked Questions (FAQ)

1. What is the typical lifespan of steel irrigation pipes?

With proper maintenance, steel irrigation pipes can last for several decades, often ranging from 30 to 50 years.

2. Are steel irrigation pipes recyclable?

Yes, steel is fully recyclable. When the pipes reach the end of their lifecycle, they can be recycled into new steel products, reducing waste and conserving resources.

3. How can I prevent corrosion in steel pipes?

To prevent corrosion, consider using galvanized steel, apply protective coatings, perform regular maintenance, and implement cathodic protection methods if applicable.

4. Can I use steel pipes for residential irrigation systems?

Yes, steel pipes can be used for residential irrigation systems, especially in larger properties that require efficient water distribution. However, the installation should comply with local regulations.

5. What factors should I consider when choosing irrigation pipes?

Consider factors such as the diameter, length of runs, pressure requirements, soil conditions, local climate, and budget constraints when selecting irrigation pipes.