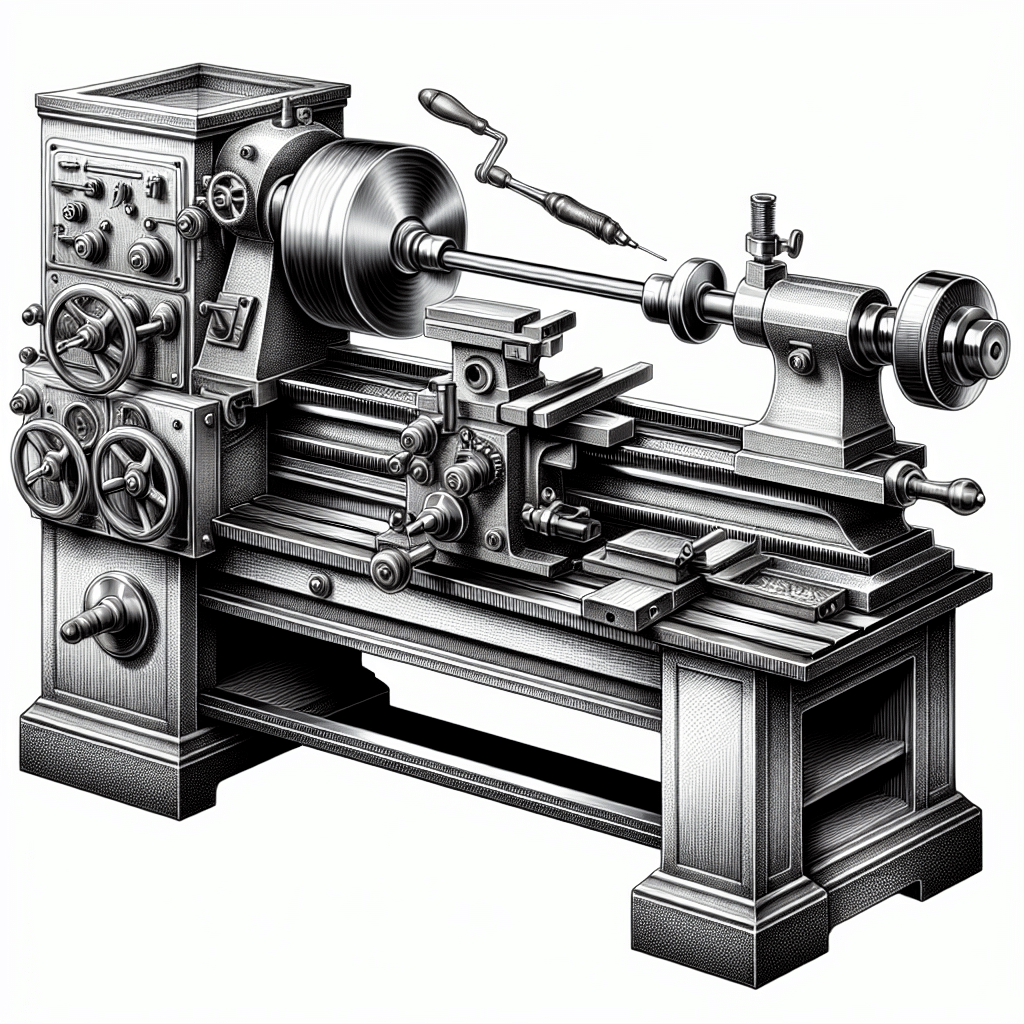

In the realm of machining, a lathe is a versatile and essential tool used for shaping and cutting materials, primarily metals and plastics. It operates by rotating the workpiece against a cutting tool, allowing for precise shaping, drilling, turning, and finishing operations. Lathes are utilized in various applications, from creating simple objects to complex components used in engineering and manufacturing. This functional machinery is available in different types, including manual lathes, CNC (computer numerical controlled) lathes, and turret lathes, each offering unique features and capabilities to accommodate different machining requirements. By understanding what a lathe is and how it works, one can appreciate its significance in industries such as automotive, aerospace, and metal fabrication, where precision and efficiency are paramount.

Understanding the Lathe: An Overview

A lathe is a machine tool that rotates a workpiece around its axis, enabling the removal of material using a stationary cutting tool. This process, known as turning, is fundamental in machining and serves various industries by creating cylindrical and conical shapes, as well as complex profiles. Initially developed for woodturning, modern lathes have evolved to accommodate diverse materials and complexities.

Types of Lathes

There are several types of lathes, each tailored for specific applications:

- Manual Lathes: These are operated by hand, allowing the machinist to control the tool’s movements and settings for customization. They are widely used in workshops and educational settings.

- CNC Lathes: Computer numerical control lathes automate the machining process using programmed commands. This enhances precision and repeatability, making them suitable for mass production and intricate designs.

- Turret Lathes: These are equipped with a rotating turret that holds multiple tools, allowing for efficient and rapid tool changes during operations. They are commonly used for batch production runs.

- Bench Lathes: Smaller in size, these lathes are ideal for hobbyists and light-duty applications. They are often used for precision tasks such as jewelry making or model building.

The Mechanics Behind Lathes

Understanding a lathe’s mechanisms can deepen appreciation for its functionality. A typical lathe consists of several key components:

- Headstock: Houses the motor and spindle. The spindle rotates the workpiece, which is usually mounted on a chuck or faceplate.

- Tailstock: Located opposite the headstock, it can support the other end of the workpiece. It also accommodates drilling and tapping operations.

- Bed: The main structure that supports the headstock and tailstock. It provides a stable foundation for machining operations.

- Carriage: Contains the sliding components that hold the cutting tool. It moves along the bed and allows adjustments to different cutting positions.

- Cross-Slide: Permits lateral movements of the cutting tool, enabling more complex shapes and cuts on the workpiece.

How Lathes Work

The operation of a lathe primarily involves the following steps:

- The workpiece is secured to the spindle via a chuck and rotated at a desired speed.

- The cutting tool is brought into contact with the material, removing excess material as it travels along the workpiece.

- Adjustments can be made for depth of cut and feed rate, influencing the shape and finish of the product.

Applications of Lathes

Lathe machines hold vast significance across many industries:

Manufacturing

In manufacturing, lathes produce various components, from screws and bolts to complex engine parts. Their ability to achieve high precision correlates with the quality standards of modern production.

Aerospace

The aerospace industry uses lathes to create components that require stringent quality assurance and lightweight materials that must withstand extreme conditions.

Automotive

Automotive engineers utilize lathes for tasks such as crankshaft and camshaft manufacturing, emphasizing the lathe’s role in safe and reliable vehicle production.

Advantages of Using a Lathe

Lathes provide numerous benefits for manufacturers and machinists:

- Precision and Accuracy: Lathes enable highly precise operations, reducing material waste and improving overall quality.

- Versatility: They can be employed for multiple tasks, such as turning, drilling, and threading, offering flexible solutions for various projects.

- Ease of Use: Despite the complexity of CNC lathes, even manual models remain user-friendly, especially with the right training.

Challenges and Limitations

Despite their advantages, lathes also face challenges:

- Skill Requirement: Operating a lathe, particularly manual types, demands significant skill and understanding of machining processes.

- Initial Investment: High-quality CNC lathes can represent a considerable financial investment, which might not be feasible for smaller operations.

- Maintenance Needs: Regular maintenance is essential to ensure precision and longevity, which can add to overall operational costs.

Safety Considerations When Operating a Lathe

Safety is paramount when working with lathes:

- Always wear appropriate personal protective equipment (PPE) such as goggles, gloves, and ear protection.

- Keep the work area clean and free of obstacles to prevent accidents.

- Be familiar with emergency shut-off procedures and maintain a safe distance from moving parts.

FAQ Section

What materials can be used on a lathe?

A lathe can work with various materials, including metals like aluminum, steel, and brass, as well as plastics and wood, depending on the lathe’s design and tooling.

How do I maintain a lathe?

To maintain a lathe, regularly check and clean all parts, lubricate moving components, and ensure that cutting tools are sharp. Periodic calibration may also be necessary to maintain precision.

Can I use a lathe for wood turning?

Yes, lathes are widely used in woodturning applications. Wood lathes, specifically designed for this purpose, have unique features tailored to working with wood materials.

What is the difference between a CNC lathe and a manual lathe?

A CNC lathe is controlled by computer programming, allowing for automated, precise cutting operations, whereas a manual lathe requires the machinist to perform all adjustments and controls by hand.

Conclusion

A lathe remains one of the most vital tools in machining, renowned for its versatility and efficiency. By understanding its varying types, how it functions, and its applications, you empower yourself or your organization to leverage its capabilities effectively. Whether in woodworking or high-precision engineering, mastering the lathe opens many opportunities for innovation and productivity.