What is a muting cable?

A muting cable is a critical component in safety circuit design, particularly in industrial and automation settings. It is designed to temporarily disable safety devices, such as light curtains or safety mats, during specific operations. This allows for uninterrupted equipment operation while maintaining necessary safety protocols.

Typically connected to an emergency stop (E-stop) system, the muting cable can initiate a lack of detection, thus permitting the machine to continue operating under controlled conditions. This feature is essential to enhancing efficiency without compromising safety standards. Overall, muting cables serve as a practical solution to maintain productivity while ensuring compliance with safety regulations.

Understanding Muting Cables

In a world where industrial safety and efficiency are paramount, understanding the role of a muting cable is essential. By learning more about this component, you can appreciate how it contributes to enhanced safety and operational efficiency in various settings, including manufacturing, robotics, and automated machinery.

1. Definition and Purpose

A muting cable is an electric or electronic interface that directly interacts with safety devices to regulate their operation. It’s commonly used in conjunction with safety sensors like light curtains, enabling temporary muting (disabling) of detection functions during predetermined conditions. Its primary purpose is to provide a safe method of operation, allowing workers to perform necessary tasks without the regular interruptions that safety devices typically impose.

1.1 Operational Context

When a machine’s safety system is activated, the muting cable can cut power to the sensors responsible for detecting obstructions. For instance, when a worker passes through a light curtain, the safety system may halt machine operation. However, with a muting cable in place, operators can work effectively without continuous interruptions, typically during routine tasks where the risks are managed.

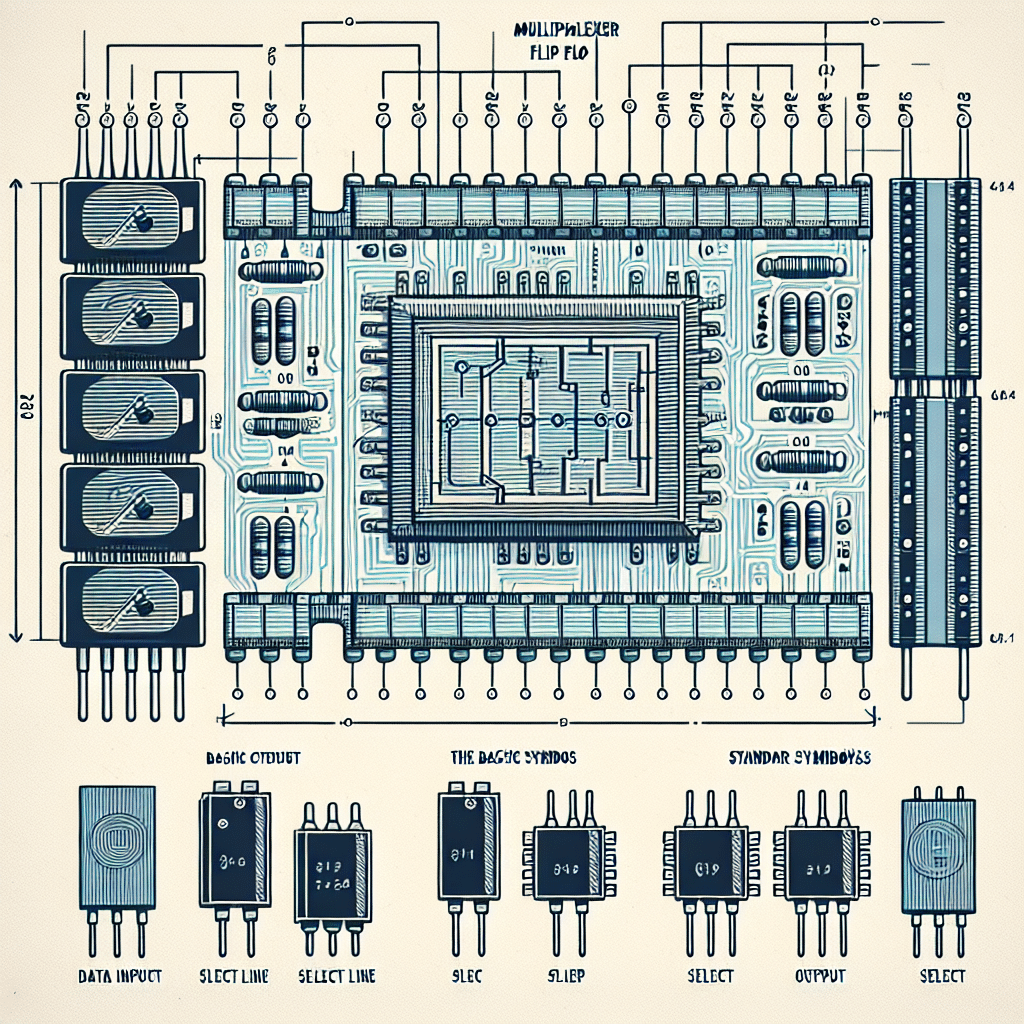

2. Components and Functionality

Muting cables can be composed of various components, including connectors, cables, and signal relays. Understanding these components will provide insights into functionality and adaptability for specific applications.

2.1 Connectors

Connectors are crucial for linking the muting cable to safety sensors and the control system. They ensure reliable electrical connections that facilitate smooth communication between safety devices and operational systems.

2.2 Cables

The quality and type of cable used will dictate the robustness of the muting system. Typical materials can include shielded or unshielded cables, with shielding often required to prevent interference from electromagnetic sources.

2.3 Signal Relays

Signal relays play a critical role in managing the status of muting. They allow signals from the muting cable to either permit normal operations or trigger safety stops when necessary.

3. Applications of Muting Cables

Muting cables find extensive applications across various industries, demonstrating their versatility and essential utility in automated systems.

3.1 Industrial Automation

In automated manufacturing lines, muting cables are employed to enhance productivity. They reduce the frequency of machine stops, allowing for continuous operation that aligns manufacturing speed with safety practices.

3.2 Robotics

In robotic systems, muting cables enable robots to function in proximity to human operators without halt. As robots can perform repetitive tasks, the ability to mute safety sensors allows tasks to occur swiftly while ensuring that human safety is preserved.

3.3 Packaging Machines

In the packaging sector, muting cables can be used with light curtains to maintain seamless operation while workers participate in packaging processes. This helps streamline operations and reduce downtime.

4. Advantages of Using a Muting Cable

Incorporating muting cables into industrial setups offers a range of advantages:

- Increased Productivity: By minimizing unnecessary machine stops, operations can run more efficiently.

- Enhanced Worker Safety: While allowing machines to remain operational, muting cables ensure that safety regulations are adhered to.

- Improved Flexibility: The design of muting cables can be adapted for multiple configurations depending on specific operational needs.

5. Regulatory Standards and Compliance

Like all safety components, muting cables must adhere to stringent regulatory standards to ensure their appropriateness and reliability. Key standards include:

- ISO 13849: This standard outlines safety-related parts of control systems and is vital in determining the required performance levels of muting devices.

- IEC 61496: Addressing safety of non-contact sensors, this standard provides guidelines for the design and use of muting cables in conjunction with safety sensors.

- OSHA Regulations: Employers are obliged to protect workers from hazards and must closely adhere to OSHA recommendations regarding safety equipment.

6. Safety Considerations and Best Practices

Implementing muting cables requires knowledge of safety practices to minimize risks:

- Regular Maintenance: Periodic checking and servicing of muting cable systems are necessary to guarantee functionality.

- Training Personnel: Educate employees on how to use muting systems safely and effectively to prevent mishaps.

- Monitoring Performance: Keep track of system performance metrics to determine any irregularities that may indicate malfunctions.

7. Frequently Asked Questions (FAQ)

7.1 What is the difference between a muting cable and a regular safety sensor?

A muting cable is specifically designed to interact with safety sensors to temporarily disable their detection capabilities during specific operational conditions, while regular safety sensors continuously monitor the working environment without providing a disabling function.

7.2 Can muting cables be used in all industries?

While muting cables are most commonly found in manufacturing and automation contexts, they can be utilized in various industries wherever temporary disabling of safety sensors is needed without compromising worker safety.

7.3 Are muting cables safe?

When installed and maintained properly in accordance with industry standards, muting cables are safe and significantly contribute to operational efficiency while adhering to safety protocols. Regular audits and assessments are necessary to ensure they remain effective.

7.4 How do I choose the right muting cable for my application?

Choosing the right muting cable involves assessing the specific needs of your operation, including safety standards, the type of machinery in use, and the operational environment—consulting with safety system experts can also assist in making an informed choice.

8. Conclusion

In summary, muting cables are essential components that improve safety and efficiency in various industrial applications. Understanding their function and benefits is crucial in navigating the complexities of safety systems in modern automated environments. By promoting responsible use and maintenance, organizations can leverage muting technology while ensuring compliance with safety regulations and protecting their workforce.