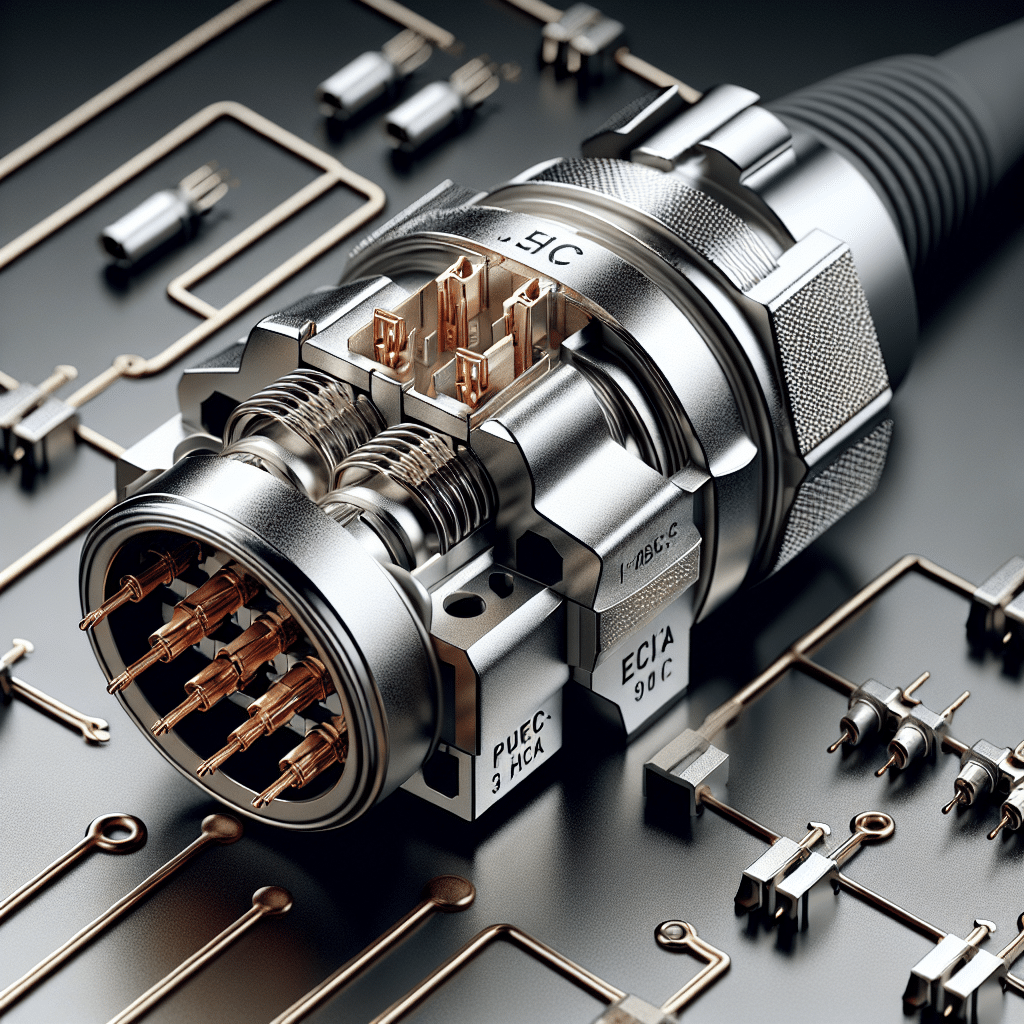

The Prevectron 3 connector is an essential component used in various electron communication systems, particularly in industrial environments and scientific research. Its primary purpose is to facilitate the reliable and effective transmission of signals within high-voltage applications, commonly associated with high-frequency, high-voltage systems, such as ionizers, RF generators, and plasma applications. The connector ensures minimal signal loss, high insulation resistance, and the ability to operate under significant electrical stress. Due to its robust design, the Prevectron 3 connector can withstand harsh conditions while maintaining optimal performance, making it a vital element for ensuring the continuity and reliability of electrical systems in demanding settings.

1. Overview of the Prevectron 3 Connector

The Prevectron 3 connector is specifically designed to meet the requirements of high-voltage applications that require the transmission of electrical signals without significant loss or interference. Its design reflects a keen understanding of both electrical engineering principles and practical applications, making it a staple in numerous industries, including semiconductor manufacturing, medical equipment, and industrial processing.

2. Design and Features

This connector typically boasts several defining features:

- High Voltage Ratings: The Prevectron 3 connector can handle high voltage levels, often exceeding 10 kV, which makes it suitable for demanding applications.

- Superior Insulation: The materials used in the construction of the Prevectron 3 provide excellent insulation properties, minimizing the risk of arcing and electrical short circuits.

- Robust Construction: Built to endure harsh environments, the Prevectron 3 is resistant to mechanical stress, temperature fluctuations, and chemical corrosion.

- Ease of Connection: Its user-friendly design allows for quick and easy assembly without requiring specialized tools, reducing downtime during maintenance or installation.

3. Applications of Prevectron 3 Connectors

Prevectron 3 connectors find usage across various applications, each demanding specific qualities from electrical connectors. Some key applications include:

3.1 Semiconductor Manufacturing

In semiconductor fabrication, these connectors are crucial in systems powering ion etchers and plasma-cleaning devices. Their high insulation ensures that delicate components remain protected during high-energy processes.

3.2 Medical Equipment

Medical devices, such as MRI machines and radiation therapy equipment, benefit from the reliable performance of the Prevectron 3 connectors, which aid in signal integrity while enduring necessary environmental conditions.

3.3 Industrial Equipment

Industries reliant on high voltage for machinery, including those in manufacturing and processing, utilize Prevectron 3 connectors for efficient signal transfer, ultimately enhancing operational safety and productivity.

4. Installation and Maintenance

Ensuring optimal performance of the Prevectron 3 connector involves following best practices during installation and maintenance:

4.1 Installation Procedures

When installing a Prevectron 3 connector, it is essential to follow manufacturer guidelines rigorously. Ensure that all connections are tight and secure to prevent electrical arcing. It is recommended to use appropriate protective gear when working with high-voltage applications.

4.2 Regular Maintenance

Regular inspections help to identify wear and tear early. Cleaning the connectors periodically from dust and contaminants can prevent performance issues. Replace any damaged parts immediately to maintain system integrity.

5. Troubleshooting Common Issues

Despite their robust design, users might encounter issues with Prevectron 3 connectors. Here are a few common problems and their potential solutions:

5.1 Signal Loss

If you experience signal loss, inspect the connector for signs of wear, corrosion, or loose connections. Tightening connections and ensuring clean contact points can often rectify these issues.

5.2 Arcing

Arcing can indicate that the connector is not rated for the voltage it is handling or that it has become compromised. It’s crucial to assess the connector’s specifications and replace it if necessary.

6. FAQ Section

What is the main purpose of a Prevectron 3 connector?

The primary purpose of the Prevectron 3 connector is to enable reliable signal transmission in high-voltage applications, minimizing losses and ensuring optimal performance.

Where is the Prevectron 3 connector commonly used?

It is commonly used in semiconductor manufacturing, medical devices, and various industrial processes that require high-voltage signal transmission.

How do I maintain a Prevectron 3 connector?

Regularly inspecting for wear, cleaning to remove contaminants, and ensuring tight connections can help maintain the Prevectron 3 connector.

What should I do if I experience arcing?

If arcing occurs, check the voltage levels and connector integrity. Replace it immediately if it has sustained damage or is not rated for the applied voltage.

7. Conclusion

The Prevectron 3 connector stands as a reliable component in high-voltage industrial and scientific applications. Understanding its design, features, and best practices for installation and maintenance is vital. By ensuring proper use and addressing issues proactively, you can significantly enhance the performance and longevity of your high-voltage systems. For further inquiries or specific technical advice, consulting the manufacturer or professional engineers is recommended.