Introduction

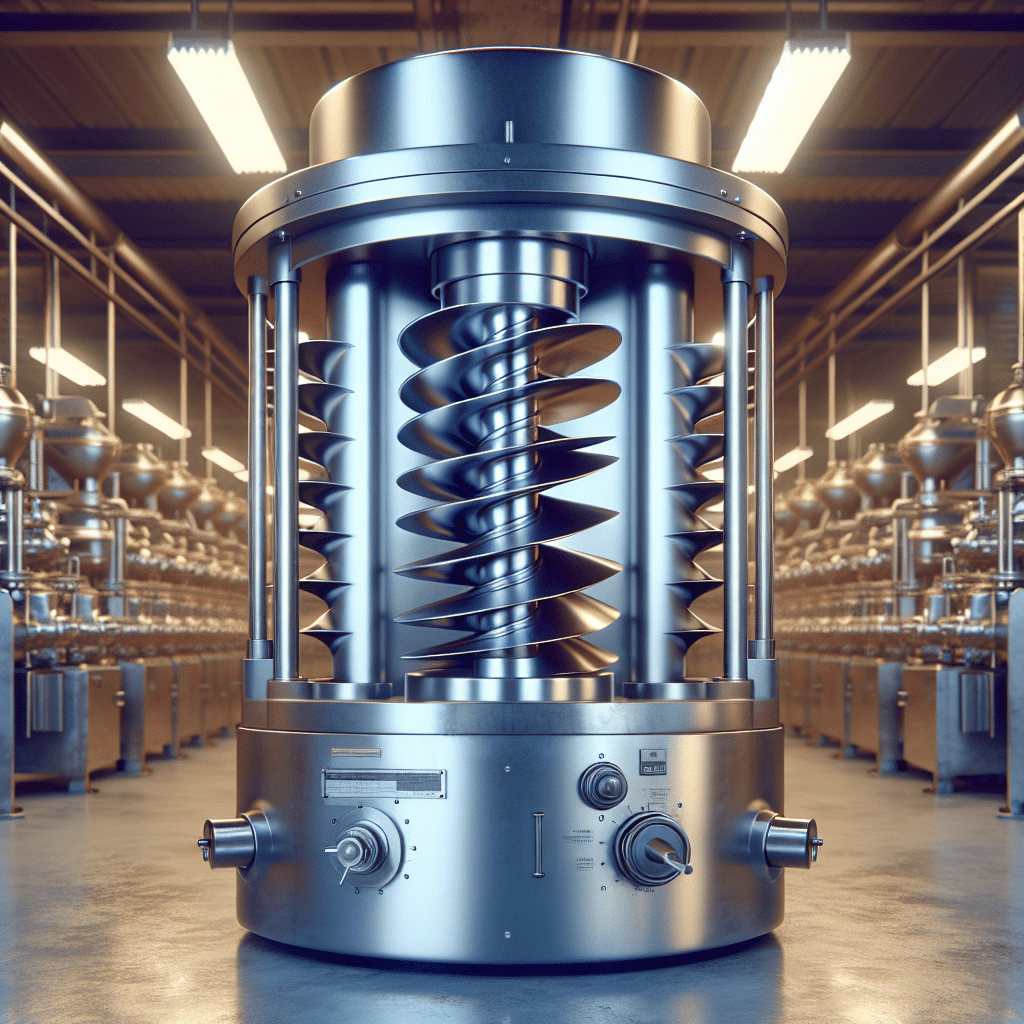

A ribbon blade mixer is an industrial mixing machine commonly used to blend dry powders, granules, and even some liquid ingredients. The design features a horizontal mixing chamber containing a set of ribbon-shaped blades that rotate around a central shaft. These ribbons facilitate the movement of materials from the center of the mixer toward the outer edges and back again, ensuring thorough and consistent mixing. This type of mixer excels in achieving a homogeneous mixture with minimal product degradation, making it ideal for applications in food processing, pharmaceuticals, chemicals, and more.

Understanding Ribbon Blade Mixers

Ribbon blade mixers play a critical role in various industries. To fully appreciate their function and benefits, it is essential to delve deeper into their design, operation, and applications.

Design and Mechanics

At the core of a ribbon blade mixer is its unique design. Typically made from stainless steel or other robust materials to ensure durability, the horizontal mixing chamber is where the blending magic occurs. The ribbon blades are spiral-shaped and can be configured in different ways depending on the specific mixing needs.

- Blades Configuration: The blades can be arranged for dual or single ribbon movement. A dual ribbon configuration allows passage in two opposite directions, enhancing mixing efficiency.

- Mixing Chamber: The chamber is often equipped with discharge openings that facilitate easy unloading of mixed content.

- Drive System: The mixer is typically powered by an electric motor that drives the blades’ rotation, ensuring flexibility in speed control.

How It Works

The operation of a ribbon blade mixer relies on the continuous motion facilitated by the blades. As the mixer operates, the ribbons move materials from the center to the edges, while simultaneously pulling content from the edges back to the center. This counter-current action enhances the mixing process, delivering high-quality results. Additionally:

- Distribution: Powder and other components are distributed evenly throughout the mixture.

- Homogeneity: The thorough mixing leads to a uniform product with minimal clumping.

- Mixing Time: Ribbon blade mixers typically achieve desired mixing results in a fraction of the time required by conventional mixers.

Advantages of Ribbon Blade Mixers

Utilizing ribbon blade mixers offers multiple advantages that enhance operational efficiency across various industries.

1. Versatility

These mixers can handle a broad range of materials, from powders to granules and even negligible amounts of liquids. This versatility makes them suitable for various applications, including:

- Food production: Mixing flour, sugar, and other dry ingredients

- Chemical processing: Mixing powders and granules for chemical reactions

- Pharmaceuticals: Creating homogenous mixtures of active pharmaceutical ingredients

2. Efficiency

Ribbon blade mixers are designed for rapid and thorough mixing. They minimize operational time without compromising quality, resulting in increased productivity. The continuous mixing action reduces the time needed to achieve a consistent blend.

3. Gentle Mixing

Unlike other high-shear mixers, the ribbon blade design provides gentle mixing, reducing the risk of product degradation. This is particularly crucial for sensitive materials that may be adversely affected by aggressive blending.

4. Ease of Cleaning

Many ribbon blade mixers have surfaces designed for easy cleaning, which is essential in industries where hygiene and product integrity are paramount. The ability to quickly disassemble and clean the machinery reduces downtime and helps maintain operational flow.

Applications of Ribbon Blade Mixers

The applications of ribbon blade mixers span numerous sectors. Here, we explore some key areas where they are extensively used:

1. Food Industry

In food processing, ribbon blade mixers are instrumental in blending various ingredients such as flour, sugar, spices, and dry seasonings. The ability to achieve homogeneity is crucial for product consistency, making these mixers vital in bakeries, snack production, and other culinary applications.

2. Chemical Manufacturing

The chemical industry frequently employs ribbon blade mixers to combine solid materials, particularly in the production of fertilizers, detergents, and other powdered chemicals. The gentle mixing action preserves the integrity of active ingredients while ensuring uniformity.

3. Pharmaceutical Products

In pharmaceuticals, precision is paramount. Ribbon blade mixers facilitate the blending of powder and granulate forms of drugs, enhancing the uniformity and bioavailability of active pharmaceutical ingredients. This ensures consistent dosing and improved efficacy in medicinal products.

4. Construction Materials

Ribbon blade mixers are also valuable in preparing mixtures for construction materials, such as cement, mortar, and plaster. The even distribution of additives and aggregates achieved through ribbon mixing supports the durability and performance of building materials.

Maintenance and Best Practices

To ensure the longevity and reliability of ribbon blade mixers, implementing proper maintenance protocols is crucial. Here are some key best practices:

1. Regular Cleaning

Dirty mixers can lead to cross-contamination. Regularly clean the internals after each batch or frequently to prevent residue build-up and maintain product quality.

2. Check for Wear and Tear

Regularly inspect ribbon blades and other moving parts for any signs of wear or damage. Addressing these issues early can prevent costly downtime and maintain productivity.

3. Lubrication

Ensure proper lubrication of bearings and gears to facilitate smooth operation. This reduces friction, prolongs equipment life, and enhances efficiency.

4. Regular Servicing

Schedule regular servicing and maintenance checks to ensure the mixer operates at peak performance. Following manufacturer guidelines can help detect issues that may not be apparent during regular operations.

Frequently Asked Questions (FAQ)

What materials can be mixed using a ribbon blade mixer?

Ribbon blade mixers can handle a variety of materials, including powders, granules, and small amounts of liquids. They are versatile and suitable for industries such as food, pharmaceuticals, and chemicals.

How does a ribbon blade mixer differ from other types of mixers?

Ribbon blade mixers are designed specifically for gentle mixing and homogeneous blending of dry materials. Unlike high-shear mixers, which can cause degradation, ribbon mixers provide a low-shear environment that preserves material integrity.

How long does it take to achieve a homogeneous mix?

The mixing time varies depending on factors such as material type and desired consistency. Generally, ribbon blade mixers can achieve homogeneity in just a few minutes, significantly faster than traditional blending methods.

Are ribbon blade mixers easy to clean?

Yes, many ribbon blade mixers are designed for easy disassembly and cleaning. Regular maintenance ensures hygiene and prevents contamination between batches.

Conclusion

In conclusion, ribbon blade mixers are an essential piece of equipment in various industries due to their efficiency, versatility, and gentle mixing capabilities. By understanding their design and operation, you can select the right mixing solution that meets your specific needs, thereby ensuring high-quality, homogenous mixtures in your production processes.