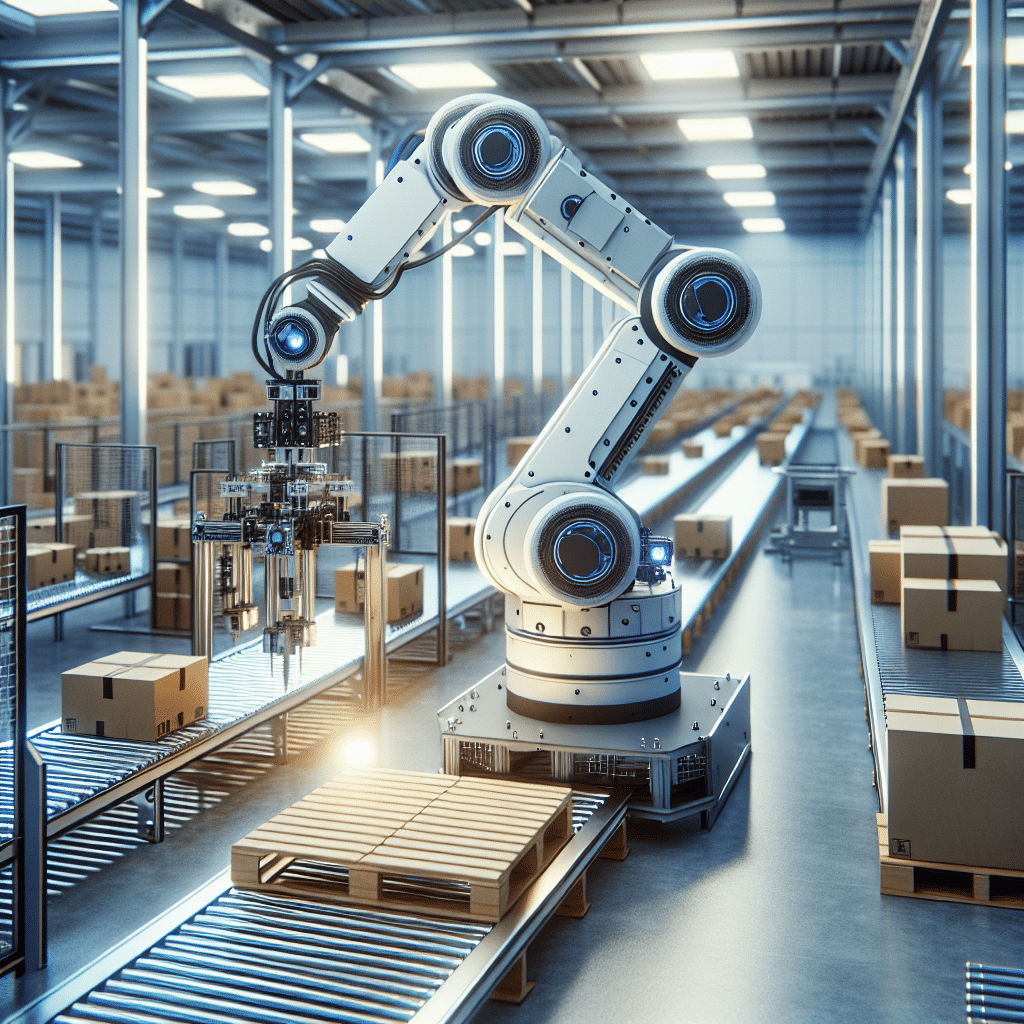

What is a robot palletizer? A robot palletizer is an automated machine that uses robotic arms to handle the process of stacking products onto pallets. These sophisticated systems are designed to increase efficiency and accuracy in the packaging and shipping processes within various industries, especially in manufacturing and logistics. Robot palletizers can handle a wide range of products, from boxes to bags, providing a flexible solution that reduces labor costs and minimizes human error. They are often equipped with advanced features such as vision systems and artificial intelligence, allowing them to adapt to different product types and sizes seamlessly. By integrating robot palletizers into production lines, companies can enhance their throughput, improve safety, and maintain high standards of quality control.

Understanding Robot Palletizers

Robot palletizers represent a significant technological advancement in the automation of warehousing and distribution operations. In simple terms, these are robotic systems tasked with the reliable and efficient organization of goods onto pallets for shipping or storage purposes. The development of this technology stems from the ever-growing requirements for efficiency and accuracy in material handling.

How Robot Palletizers Work

Components of a Robot Palletizer

Robot palletizers typically consist of several key components:

- Robot Arm: The core component, usually articulated, that executes the movement of picking, placing, and stacking products.

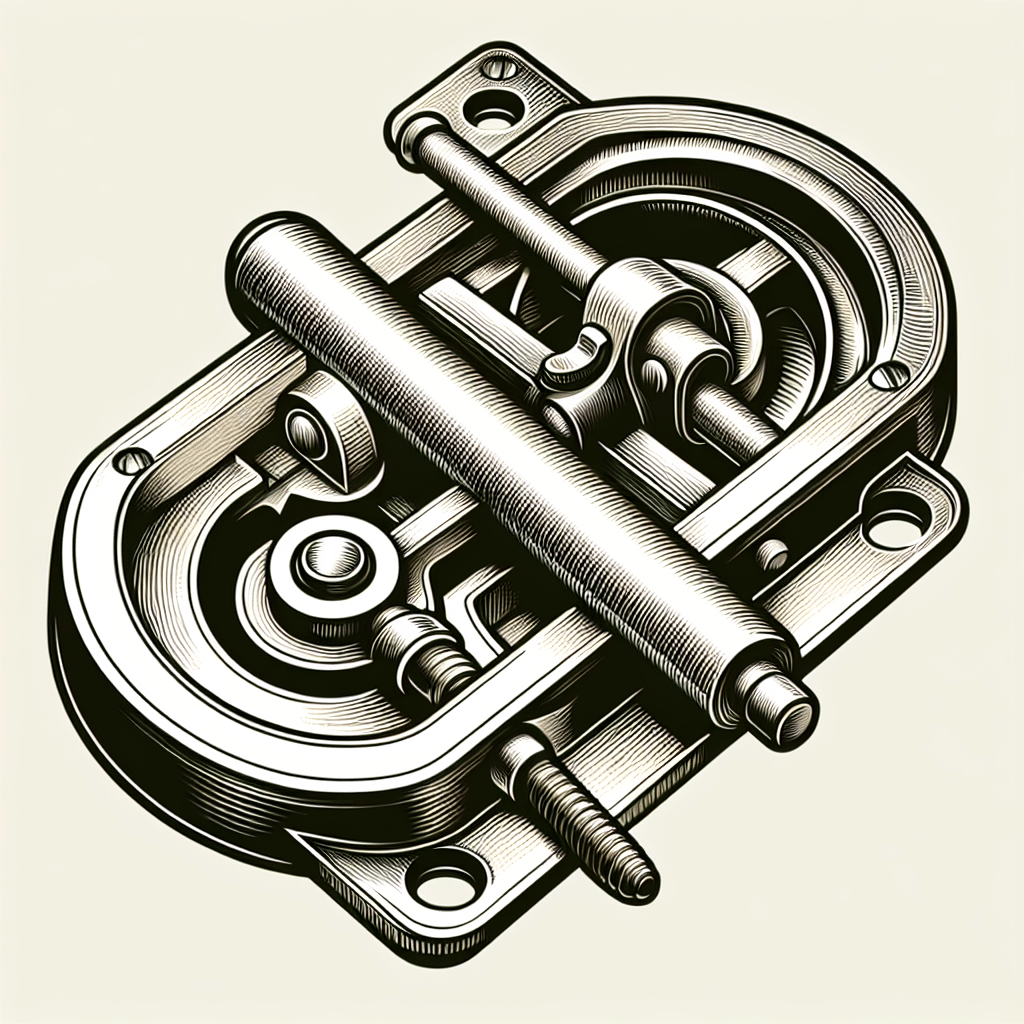

- End-of-Arm Tooling (EOAT): Specialized attachments at the end of the robot arm tailored to the product type, ensuring secure handling.

- Vision Systems: Cameras and sensors that help in identifying and locating products, enhancing accuracy.

- Control System: Software or hardware that manages the robotic operations and coordinates with other machinery.

- Conveyor Systems: Transport the products to and from the palletizer, streamlining the workflow.

The Process Flow

The operational cycle of a robot palletizer generally includes:

- Product Detection: The vision system detects incoming products on the conveyor.

- Pallet Picking: The robot arm retrieves the product using the EOAT.

- Product Placement: The product is placed onto the designated pallet in a specified pattern.

- Stacking: The process repeats until a full pallet is assembled.

- Discharge: The completed pallet is removed from the line for further processing.

Benefits of Robot Palletizers

Increased Efficiency and Productivity

Robot palletizers enhance production efficiency significantly. They can operate continuously without the fatigue experienced by human workers, leading to higher output rates. According to a study by the Association for Advancing Automation, companies often report productivity increases of 30% or more after implementing robotic solutions.

Improved Accuracy and Reduced Waste

With advanced vision systems and precise programming, robot palletizers minimize errors in product placement that can lead to damages and waste. The consistency of robotic operations ensures that each pallet meets the required specifications.

Enhanced Safety

By automating the palletizing process, the risks of workplace injuries related to heavy lifting are significantly reduced. This automation allows human workers to focus on more strategic tasks while robots handle the physically demanding operations.

Cost Savings

While the initial investment in robot palletizers can be substantial, the long-term savings in labor costs, reduced injuries, and increased output often lead to a quick return on investment. Furthermore, maintenance costs for robots are typically lower than for human labor when considering the total cost of employee benefits and compensation.

Types of Robot Palletizers

Articulated Robots

These robots have rotary joints and offer a high degree of flexibility, making them suitable for diverse product shapes and sizes. They are ideal for applications that require intricate stacking patterns.

SCARA Robots

SCARA (Selective Compliance Assembly Robot Arm) robots provide high-speed and high-precision operations. They excel in tasks that require horizontal movements and are effective for repetitive picking operations.

Delta Robots

Known for their speed and efficiency, delta robots are designed for light payloads and are particularly useful for handling rapid throughput applications. Their unique design allows for quick and agile movements.

Implementation Considerations

Space and Layout

When planning for a robot palletizer, consider the available space in the operational environment. The layout should accommodate both the robotic system and the associated conveyor systems without disrupting existing workflows.

Product Types and Palletization Patterns

Different products may require distinct palletization patterns. It’s crucial to design the palletizer based on the product specifications, including weight, shape, and fragility. This ensures optimal performance and safety during handling.

Software Integration

Effective integration with existing inventory management and production systems is essential to maximize the benefits of a robot palletizer. The control software should facilitate seamless communication with other machinery and operational workflows.

Future Trends in Robot Palletizers

Advanced AI and Machine Learning

The incorporation of AI and machine learning into robot palletizers is improving their adaptability. Robots can learn from previous operations and make real-time adjustments, increasing process efficiency and reducing errors.

Collaborative Robots (Cobots)

Cobots are designed to work alongside human operators. They allow for flexible applications and are easily programmable, making them an ideal solution for smaller operations that do not require full automation.

Sustainable Practices

As industries strive for sustainability, robot palletizers are being designed to operate with reduced energy consumption and minimal waste, further enhancing their appeal in the modern market.

Case Studies and Practical Examples

Food and Beverage Industry

Companies such as SVP Solutions have successfully integrated robot palletizers in their lines, improving their packaging processes and increasing productivity while maintaining high standards of food safety.

Consumer Goods Manufacturing

In consumer goods, organizations like ABB Robotics have demonstrated the effectiveness of robotic solutions in managing high-volume operations with varying product types, achieving significant improvements in operational efficiency.

Frequently Asked Questions (FAQ)

What is the average cost of a robot palletizer?

The cost of robot palletizers can vary widely based on their complexity, capacity, and features. Generally, prices range from $25,000 to upwards of $250,000, including installation and training.

How much space do robot palletizers typically require?

The space required depends on the specific model and its configuration. Typical setups can require as little as 10×10 feet to accommodate the robot, peripherals, and safety zones.

Can robot palletizers handle fragile products?

Yes, with the right end-of-arm tooling and programming, robot palletizers can be customized to handle fragile items with care, avoiding damage during the palletizing process.

How do I determine if my operation needs a robot palletizer?

Consider the volume of products, labor costs, potential injury risks, and efficiency goals. If your operation experiences bottlenecks during the palletizing process, a robot palletizer may be a suitable investment.

Conclusion

Robot palletizers have transformed the landscape of material handling in industries worldwide. They offer numerous advantages, including increased efficiency, reduced labor costs, and enhanced safety. As they continue to evolve with advanced technology, they represent a strategic investment for companies looking to streamline their operations and improve their competitive edge. Embracing automation through robot palletizers not only facilitates growth but also positions businesses accordingly in an increasingly automated future.