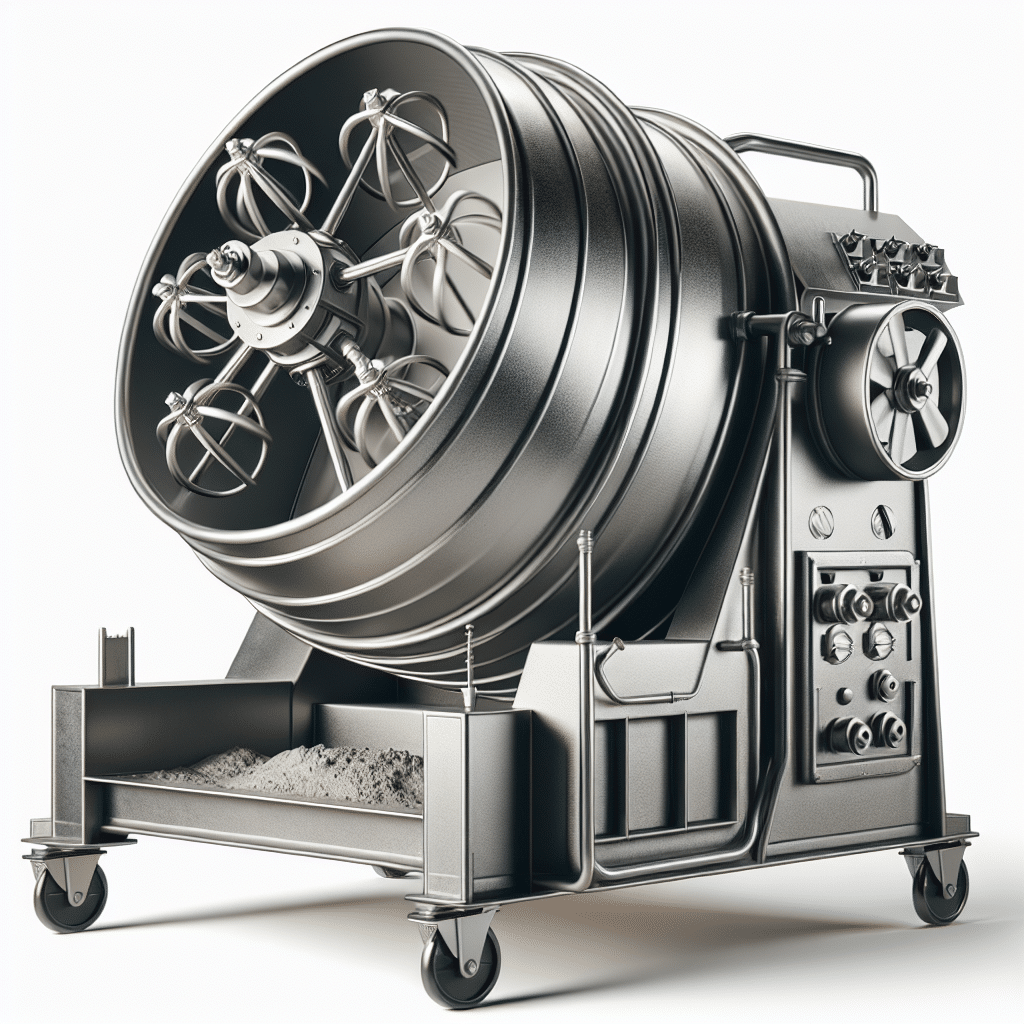

What is a rotating pan mixer? A rotating pan mixer is a type of equipment widely used in construction, particularly for mixing concrete, mortar, and other materials. Characterized by its circular mixing pan that rotates on a horizontal axis, the device enhances the uniformity and consistency of the mixed materials. This mixer operates efficiently by using tilting or rotating motion combined with specific blades designed to optimize the mixing process. The design facilitates a thorough combination of ingredients, including aggregates, cement, water, and admixtures, ensuring that the final product meets precise specifications. Rotating pan mixers are vital in producing high-quality concrete mixes that are essential for various construction applications, ranging from small-scale projects to large industrial processes. Their ability to achieve uniform mixtures quickly minimizes waste and reduces labor, making them an indispensable tool in the industry.

Understanding Rotating Pan Mixers

Rotating pan mixers play a crucial role in the construction industry, offering advantages in terms of efficiency, consistency, and product quality. To fully grasp their significance, it’s essential to understand their construction, operational mechanism, and applications. This section breaks down these aspects in detail.

Construction of Rotating Pan Mixers

Rotating pan mixers are comprised of several key components that contribute to their efficient functioning:

- Mixing Pan: The heart of the mixer, the mixing pan is often circular or oval-shaped and has a flat bottom. The interior surfaces are designed to prevent sticking and enhance mixing efficiency.

- Mixing Arms or Blades: Attached to a central shaft, these blades rotate at various speeds, depending on the design, to incorporate materials effectively. Their shape and positioning are crucial for ensuring that all ingredients are mixed thoroughly.

- Drive Mechanism: Typically powered by an electric motor or a diesel engine, the drive mechanism imparts rotational motion to the mixing pan and blades. The speed and direction of rotation can often be adjusted to suit specific mixing requirements.

- Chassis and Frame: A robust frame supports the entire assembly, providing stability during operation. Some models include wheels for mobility.

Operation of Rotating Pan Mixers

The operation of a rotating pan mixer is relatively straightforward yet expertly designed to enhance effectiveness:

- Loading: Materials such as cement, aggregates, and water are loaded into the mixing pan. Precise measurement is crucial to maintain the desired mix proportions.

- Mixing Process: Once the ingredients are loaded, the mixing pan begins to rotate. The blades facilitate a vigorous mixing action, which ensures that all components are evenly distributed. This process usually takes anywhere from a few minutes to over a quarter of an hour, depending on the desired consistency and material type.

- Discharge: After mixing is complete, the product is discharged from the mixer either by tilting the pan or through a discharge gate.

Applications of Rotating Pan Mixers

Rotating pan mixers are versatile and find applications across various sectors, most notably in:

- Concrete Manufacturing: They are extensively used to produce ready-mix concrete, precast concrete products, and concrete blocks, allowing for rapid and consistent batch production.

- Mortar Mixing: In masonry construction, these mixers provide reliable mortar blends for brick and stone laying.

- Asphalt Production: Used in conjunction with asphalt manufacturing processes, rotating pan mixers ensure proper blending of asphalt components.

- Batch Mixing of Powders: In industries beyond construction, they can also mix powders and granulates for chemical and food processing applications.

Benefits of Rotating Pan Mixers

There are multiple reasons why rotating pan mixers are preferred in the industry. Understanding these benefits can help you make informed decisions about using this equipment:

1. Improved Mixing Quality

Due to the unique design of the mixing pan and blades, tips can be mixed more uniformly compared to traditional mixers. This ensures stronger concrete with fewer defects and better durability.

2. Time-Efficiency and Productivity

Rotating pan mixers significantly reduce mixing times, which can lead to higher production rates. This efficiency is essential in high-demand scenarios where timely delivery of materials is crucial.

3. Versatility

These mixers can handle a variety of materials and mix designs, making them suitable for multiple applications. From varying aggregate sizes to different types of additives, their adaptability is highly valued.

4. Reduced Labor Costs

Automation and ease of operation mean that fewer personnel are required for mixing tasks, resulting in reduced labor expenses and increased safety on the job site.

Considerations When Choosing a Rotating Pan Mixer

When selecting a rotating pan mixer, several factors should be considered to ensure it meets your specific operational needs:

1. Capacity Requirements

Select a mixer with the right production capacity to match your workload. Larger mixers can handle bigger batches but consider the space and transport efficiency required.

2. Power Source

The choice between electric or diesel-powered mixers depends on your worksite’s availability of electricity and the nature of your projects.

3. Durability and Maintenance

Examine the construction materials and design features that enhance durability, as rotating pan mixers are subject to heavy use. Regular maintenance is necessary to achieve long-term reliability.

4. Mixer Design Features

Consider additional features such as adjustable blade speeds, tilting mechanisms, and ease of cleaning. These features can greatly enhance operational efficiency and convenience.

Maintenance and Care for Rotating Pan Mixers

Proper maintenance practices are critical in prolonging the life of rotating pan mixers. Below are some essential maintenance tips:

- Regular Cleaning: After each use, thoroughly clean the mixing pan and blades to prevent material buildup and contamination.

- Inspect Components: Conduct routine inspections of all moving parts to check for wear and damage. Replace any worn components promptly.

- Lubrication: Ensure that all moving parts are adequately lubricated to minimize friction and prevent rusting.

- Electrical Checks: For electric mixers, ensure that all electrical connections are secure and check for signs of short circuits or wear.

FAQs about Rotating Pan Mixers

What materials can be mixed in a rotating pan mixer?

A rotating pan mixer can mix a variety of materials, including concrete, mortar, and asphalt, as well as powders and granulates for different industrial applications.

How long does it take to mix concrete in a rotating pan mixer?

The mixing time in a rotating pan mixer generally ranges from 3 to 15 minutes, depending on the batch size and material type.

Can a rotating pan mixer be used for small projects?

Yes, rotating pan mixers come in various sizes, making them suitable for both small-scale and large-scale projects.

What are common issues faced with rotating pan mixers?

Common issues may include uneven mixing, excessive wear on blades, and mechanical failures. Regular maintenance can help mitigate these problems.

Are rotating pan mixers energy-efficient?

Many modern rotating pan mixers are designed to be energy-efficient, optimizing power usage without compromising performance.

Conclusion

Rotating pan mixers are an essential asset in many sectors of the construction industry, providing efficiency, consistency, and high-quality outputs. Offering comprehension into their operation, advantages, and the factors to consider when selecting a model can significantly enhance your productivity in concrete and material mixing. By understanding the benefits and optimal maintenance practices, you can ensure that your rotating pan mixer remains a reliable ally in your construction projects.