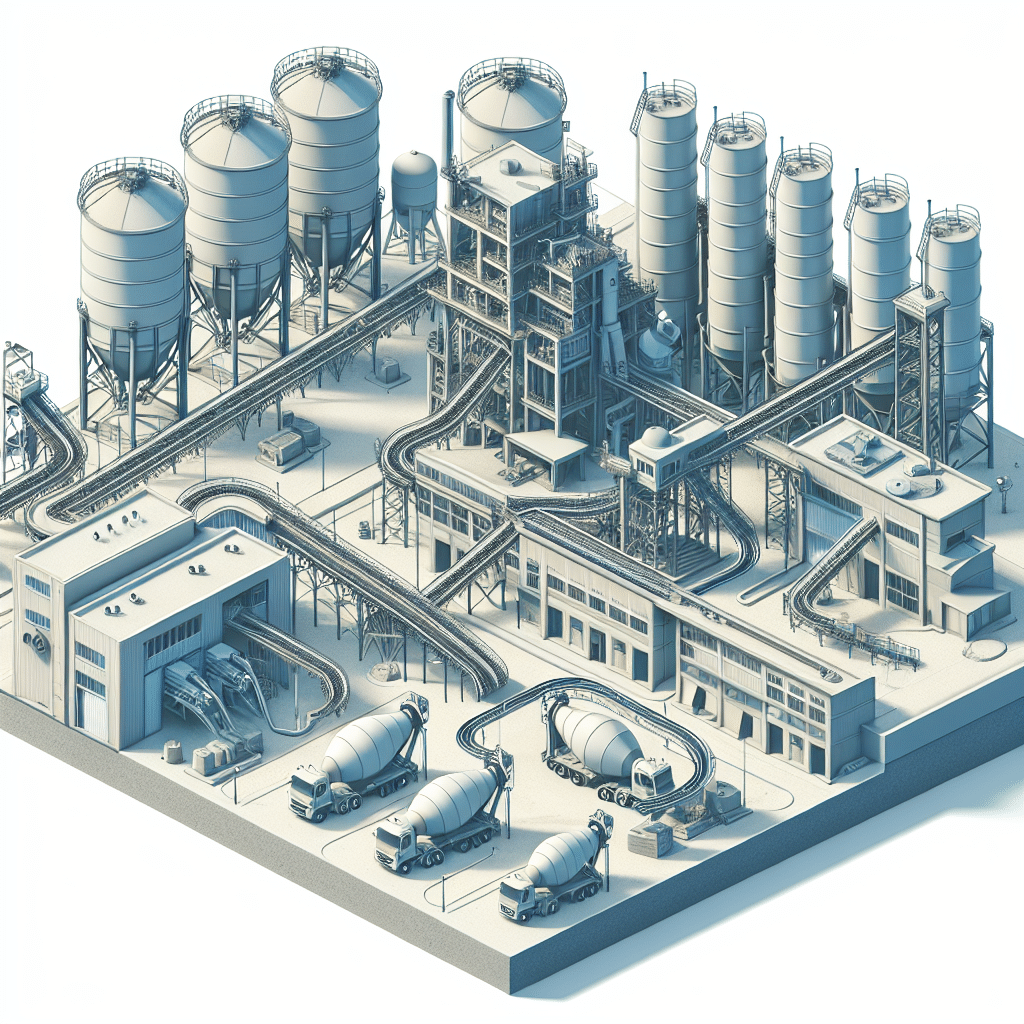

What is a Stationary Concrete Plant?

A stationary concrete plant is a fixed facility designed for the large-scale production of concrete. Its primary function is to mix various ingredients—such as cement, aggregates, water, and additives—into a consistent and high-quality concrete mix. Unlike mobile concrete plants, which are portable and can be relocated as required, stationary plants are often built in one location to serve a significant construction project or area.

Stationary concrete plants typically feature advanced technology, allowing for automated and consistent mixing processes. They come in various capacities and configurations, and may include features like silos for cement storage, aggregate bins, and centralized control systems. Their major applications include supplying concrete for roads, bridges, buildings, and other infrastructure projects, making them a vital component in the construction industry.

Understanding Stationary Concrete Plants

Stationary concrete plants represent a cornerstone of modern construction operations, designed to produce substantial quantities of concrete with precision and reliability. By understanding their components, benefits, limitations, and operational procedures, contractors and project managers can better utilize these facilities for efficient construction outcomes.

1. Components of a Stationary Concrete Plant

The typical structure of a stationary concrete plant consists of several key components:

- Batching System: This system determines the quantity of each ingredient used in the mix. There are two primary types of batching systems: volumetric batching, which measures components by volume, and weight batching, which measures them by weight for higher accuracy.

- Mixing Unit: The mixing area is where all the ingredients are combined. This could be a pan mixer, a twin-shaft mixer, or a drum mixer, depending on the desired quality and consistency of the concrete. Twin-shaft mixers are preferred for their efficiency and uniformity.

- Cement Silos: These are large storage containers for bulk cement. They maintain the integrity of the cement while protecting it from moisture and other environmental factors.

- Aggregate Bins: Aggregate storage bins hold the various aggregates—such as sand, gravel, or crushed stone—needed for concrete production. Proper management of the aggregates is crucial for achieving consistent mix quality.

- Control System: Modern plants utilize computerized systems that control and monitor the entire process, ensuring accurate measurements and consistent mixing results. This technology enhances operational efficiency and reduces human errors.

2. Benefits of Stationary Concrete Plants

- High Production Capacity: Stationary concrete plants are capable of producing large volumes of concrete, making them ideal for significant projects that require a constant supply of material.

- Quality Control: The automation and scaling of operations allow for better control over the mixing process, ensuring a homogenous and high-quality end product.

- Cost-Effectiveness: While the initial investment for stationary plants can be high, the long-term operational savings, achieved through efficiency and reduced waste, can lead to overall lower costs.

- Durability and Reliability: Built to withstand varied environmental conditions, stationary concrete plants tend to have a longer lifespan and are capable of operating continuously in production cycles.

- Scalability: These plants can be expanded to meet increasing production demands, allowing businesses to grow and adapt to market needs.

3. Limitations of Stationary Concrete Plants

Despite their advantages, stationary concrete plants are not without downsides:

- Fixed Location: Their immobility can be a limitation for projects that require frequent relocation or shorter-term developments.

- High Initial Costs: The upfront investment for infrastructure and equipment can be significant, which might be a barrier for smaller contractors.

- Longer Setup Time: Establishing and commissioning a stationary plant can take time, delaying the start of construction projects.

4. Operational Procedures

Understanding how to operate a stationary concrete plant efficiently is crucial for maximizing its potential:

- Site Selection: Choosing an appropriate location that provides access to raw materials, labor force, and transportation routes is critical.

- Equipment Maintenance: Regular maintenance of all equipment ensures smooth operations and longevity.

- Training Personnel: Skilled operators should be trained on the specific systems in use for optimal performance and safety.

- Safety Protocols: Implementing safety measures minimizes risks associated with heavy machinery and material handling.

Applications of Stationary Concrete Plants

The applications of stationary concrete plants are diverse, reflecting the needs of various sectors:

- Infrastructure Projects: Roads, bridges, and tunnels that require large quantities of concrete rely heavily on stationary plants for steady supplies.

- Residential and Commercial Construction: High-rise buildings and large complexes depend on the consistent quality and quantity of concrete.

- Precast Concrete Manufacturing: Plants can supply the necessary materials for precast concrete products, like beams, walls, or slabs.

Environmental Considerations

With growing awareness surrounding environmental sustainability, stationary concrete plants also face scrutiny regarding their operational impact:

- Dust Control: Implementing measures to control dust emissions not only aids in site cleanliness but also complies with environmental regulations.

- Waste Management: The management of concrete waste through recycling processes promotes a more sustainable operation.

- Energy Efficiency: Utilizing energy-efficient technologies reduces the carbon footprint associated with concrete production.

Frequently Asked Questions (FAQ)

What is the difference between a stationary concrete plant and a mobile concrete plant?

A stationary concrete plant is fixed in one location and is designed for high-capacity production, while a mobile concrete plant is portable and can be relocated easily for smaller, temporary projects.

How do stationary concrete plants ensure quality control?

Stationary concrete plants utilize automated batching and mixing systems to ensure precise measurements, as well as advanced control systems for constant monitoring of the mixing process.

What maintenance is required for a stationary concrete plant?

Regular maintenance includes inspections of mixing equipment, servicing of control systems, monitoring the condition of aggregate bins and silos, and adhering to safety protocols.

Can stationary concrete plants operate in extreme weather conditions?

Yes, modern stationary concrete plants are engineered to withstand various weather conditions, but operators need to account for the potential impact of extreme temperatures on concrete production and curing.

Conclusion

In conclusion, stationary concrete plants serve as crucial infrastructures in the construction sector, providing the necessary materials for various large-scale projects. By understanding their components, benefits, operational practices, and the environmental considerations surrounding their use, stakeholders can harness their potential effectively. As construction demands continue to evolve, stationary concrete plants will remain a central figure in delivering quality concrete solutions across the United States.