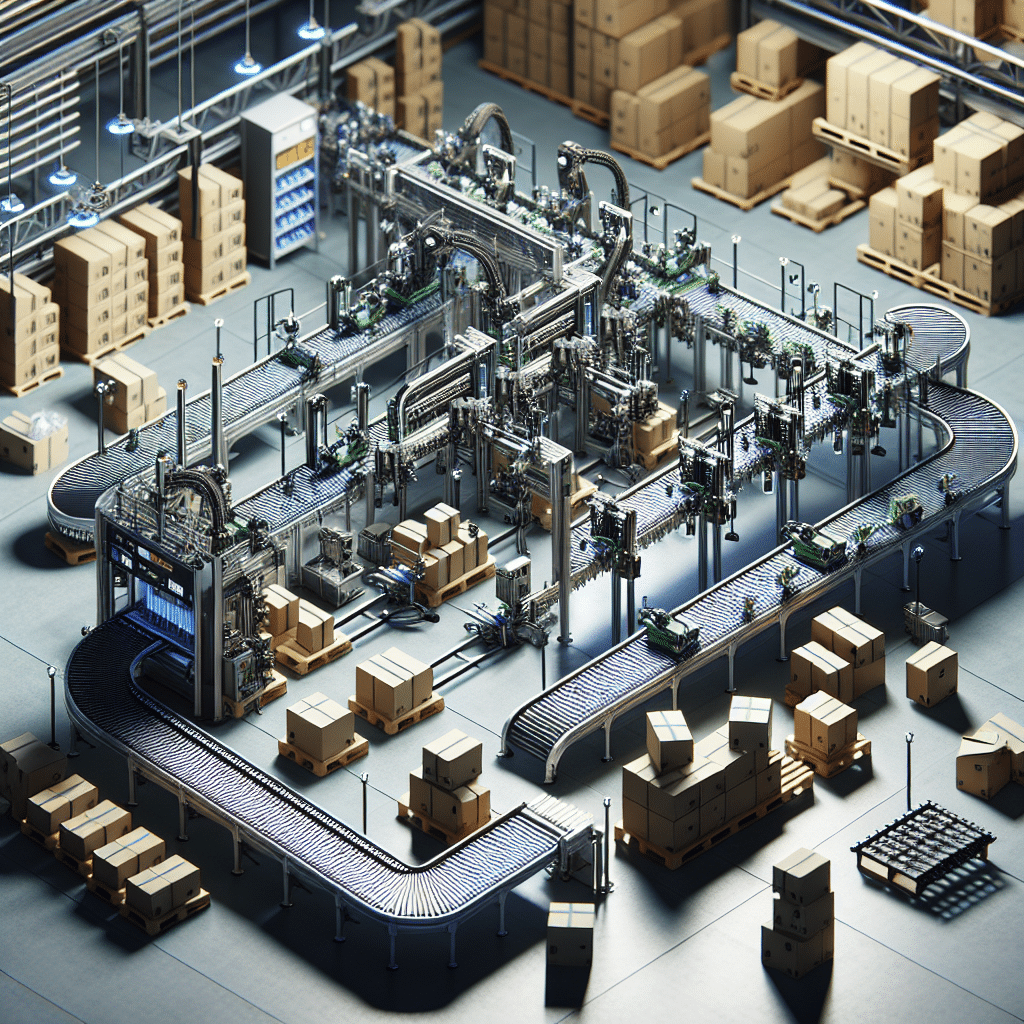

What is an In-line Palletizer?

An in-line palletizer is a sophisticated automated system designed to efficiently stack and load products onto pallets within a production line. These machines are strategically integrated into the assembly process, allowing for the direct and seamless transfer of goods from conveyors to pallets without reorientation. By optimizing space and streamlining operations, in-line palletizers offer significant labor and time savings while enhancing productivity and consistency in packaging operations. Most commonly employed in industries such as food and beverage, pharmaceuticals, and consumer products, these systems can handle various product types and are equipped with advanced technologies for precise handling and stacking.

Understanding In-line Palletizers

Definition and Functionality

An in-line palletizer is an automated machinery used in manufacturing and packaging lines that directly stacks products from conveyors onto pallets. Unlike traditional palletizers, which often introduce additional handling steps, in-line palletizers maintain the flow of goods in one continuous process. The primary function is to deliver a seamless transition of goods, ensuring that products are stacked uniformly and efficiently on pallets. This not only minimizes labor costs but also reduces the risk of product damage during handling.

Types of In-line Palletizers

In-line palletizers can be classified based on their operational mechanisms and designs:

- Robotic Palletizers: These rely on robotic arms to pick and place products onto pallets. They offer high flexibility, allowing for the handling of various product shapes and sizes.

- Conventional Palletizers: These machines typically use mechanical systems with arms or layers to transfer products onto pallets. They are often designed for high-speed operations and can handle bulk products.

- Hybrid Palletizers: Combining features from both robotic and conventional designs, hybrid palletizers provide flexibility and speed, and are adaptable to different product handling requirements.

The Workflow of In-line Palletizers

The workflow of an in-line palletizer can typically be broken down into several key stages:

- Product Handling: The in-line palletizer receives products from the production line. Products are transferred directly onto the in-line palletizer’s input conveyor, reducing the chances of misalignment.

- Arrangement: Products are organized into predefined configurations, often referred to as “patterns,” based on the pallet design. This stage is crucial for maximizing pallet space and ensuring stability during transportation.

- Stacking: Using either robotic or mechanical systems, the palletizer picks the arranged products and stacks them onto the designated pallets with precision.

- Pallet Handling: Once the pallet is fully loaded, the in-line palletizer transfers it to a stretch wrapper or a downstream conveyor for further processing, such as shipping or storage.

Benefits of In-line Palletizers

Implementing an in-line palletizer presents several advantages for manufacturers:

- Efficiency: By automating the palletizing process, operational efficiency is significantly enhanced, leading to increased throughput.

- Consistency: In-line palletizers ensure uniform stacking and organization of products, improving product handling and reducing the risk of damage.

- Space Optimization: These systems are designed to occupy minimal floor space while maximizing productivity, making them ideal for facilities with space constraints.

- Reduced Labor Costs: Automating palletizing reduces the dependency on human labor, leading to lower labor costs and minimized risk of workplace injuries.

Key Considerations When Choosing an In-line Palletizer

When selecting an in-line palletizer, several key factors should be considered:

- Product Types: Understanding the characteristics of products to be palletized, such as size, shape, and weight, is critical to selecting the right type of palletizer.

- Throughput Requirements: Assessing the number of products that need to be palletized per hour will determine the necessary speed and capacity of the machine.

- Integration with Existing Machinery: Ensure that the palletizer can seamlessly integrate with your current production line and infrastructure.

- Maintenance and Support: Consider the availability of parts and support services to keep the system running optimally.

FAQs About In-line Palletizers

1. What industries typically use in-line palletizers?

In-line palletizers are commonly used in food and beverage, pharmaceuticals, consumer goods, and industrial packaging sectors, owing to their efficiency in handling a diverse range of products.

2. How does an in-line palletizer improve productivity?

By automating stacking processes, in-line palletizers minimize handling time and human labor, resulting in faster operations with less variability, thus enhancing overall productivity.

3. Can in-line palletizers handle variable product sizes?

Yes, many modern in-line palletizers, especially robotic ones, are designed to accommodate a variety of product shapes and sizes, offering flexibility in operations.

4. What maintenance is required for in-line palletizers?

Regular maintenance involves routine inspections, lubrication of moving parts, software updates, and replacement of worn components to ensure optimal performance and longevity.

Conclusion

In-line palletizers represent a crucial advancement in the automation of packaging processes. By improving workflow efficiency, reducing labor needs, and ensuring product safety, these systems have become indispensable in modern manufacturing environments. With their various types and operational advantages, investing in an in-line palletizer could significantly enhance your production capabilities. Whether you’re in food processing, healthcare, or consumer goods, these devices tailor a solution for efficient palletizing, paving the way for smoother operations.