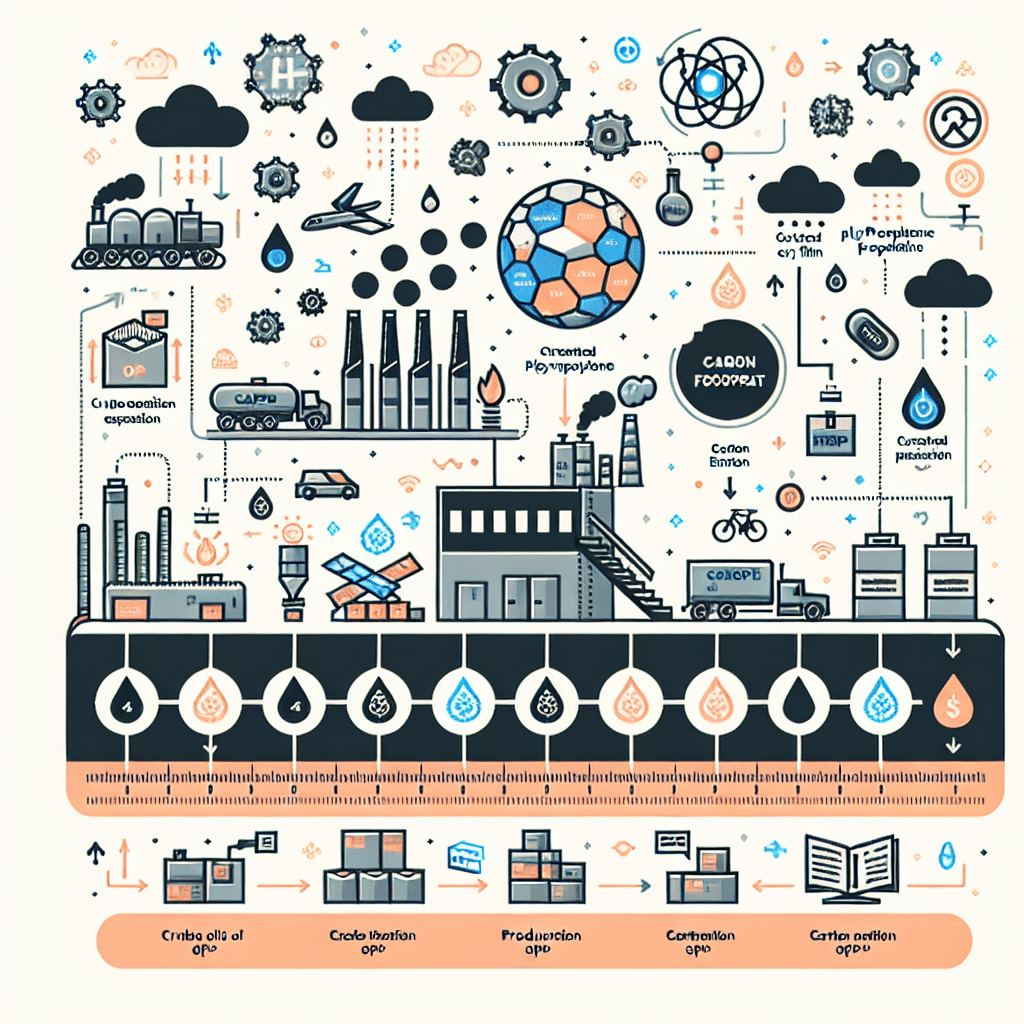

Understanding the carbon footprint of oriented polypropylene (OPP) film used in cartons is critical for businesses aiming to minimize their environmental impact while optimizing packaging solutions. The carbon footprint encompasses the total greenhouse gas emissions—expressed in carbon dioxide equivalents—produced throughout the lifecycle of OPP films, from production to disposal. Key contributors to this footprint include the extraction of raw materials, manufacturing processes, transportation, and end-of-life disposal options such as recycling and incineration. OPP films are celebrated for their excellent barrier properties and lightweight characteristics; however, their production typically relies on fossil fuels, leading to significant carbon emissions. In this context, businesses need to evaluate their packaging choices, emphasizing sustainable practices and materials, to reduce their overall carbon footprint while ensuring efficiency and product integrity.

1. Introduction to Carbon Footprint

The carbon footprint is a measure of the total greenhouse gas emissions caused directly or indirectly by an individual, organization, event, product, or service, and it plays a pivotal role in understanding environmental sustainability. In the context of packaging, especially for food and consumer goods, assessing the carbon footprint helps manufacturers make informed decisions about materials, processes, and life cycle management. You might be surprised to learn that packaging can account for a significant portion of a product’s overall environmental impact.

2. Overview of OPP Film

Oriented polypropylene (OPP) film is a type of plastic film that has been stretched in both the machine and transverse directions during production. This orientation gives the film enhanced properties, such as clarity, strength, and barrier capabilities against moisture and gases. Therefore, OPP film is commonly used in food packaging, pharmaceutical products, and consumer goods.

3. The Lifecycle of OPP Film and Its Carbon Footprint

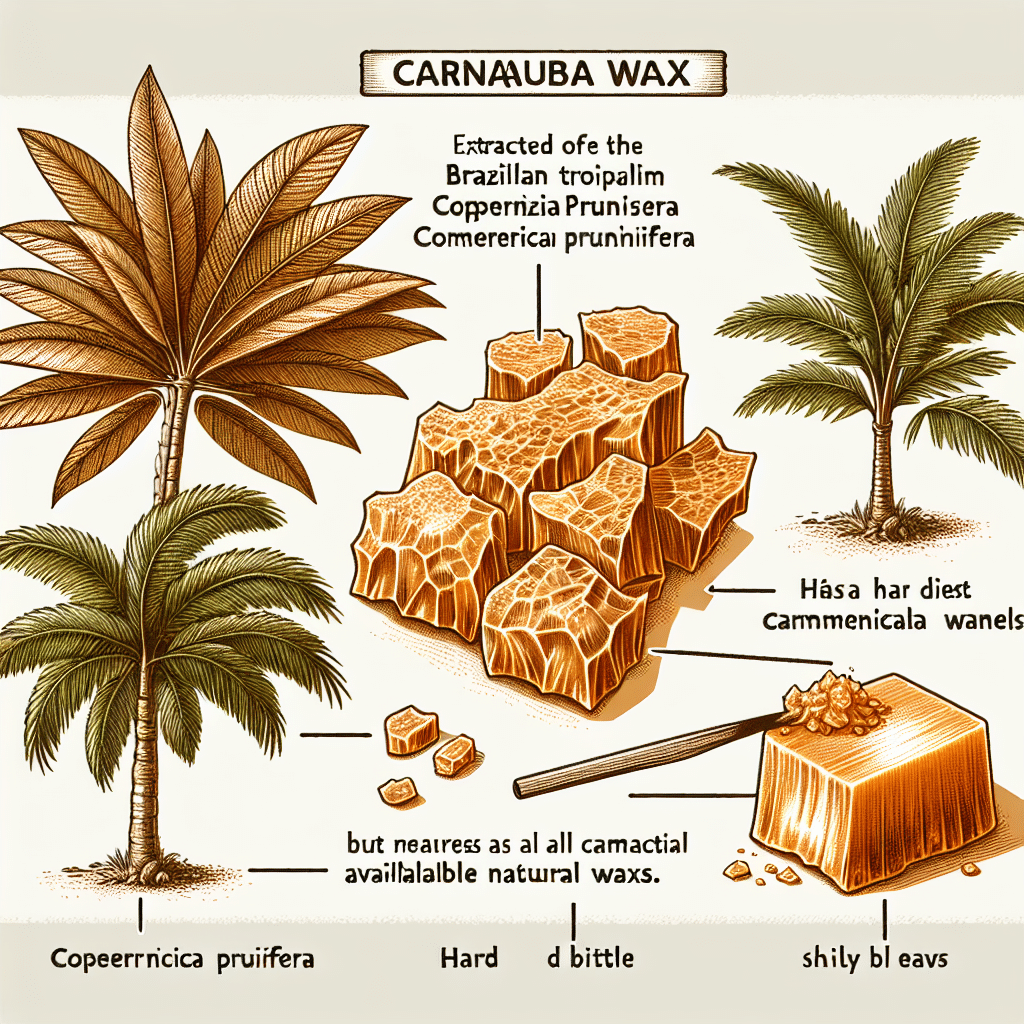

3.1 Raw Material Extraction

The production of OPP films begins with the extraction of natural gas or petroleum, which serves as the primary feedstock. This extraction process is energy-intensive, contributing significantly to the initial stages of the carbon footprint.

3.2 Manufacturing Process

The manufacturing of OPP film involves several steps, including polymerization, film extrusion, and stretching. Each of these stages requires substantial energy input and emits greenhouse gases. According to industry sources, producing one ton of polypropylene generates approximately 2.5 tons of CO2 emissions (Akhmetov et al., 2022).

3.3 Transportation

Once the OPP film is manufactured, it is transported to packaging facilities and ultimately to retailers and consumers. Transportation contributes additional emissions based on the distance traveled and mode of transport used. For instance, freight trucks tend to have a higher carbon footprint than rail or sea transport.

3.4 End-of-Life Considerations

The end-of-life phase of OPP film presents challenges, as most of it is not biodegradable and ends up in landfills. Although OPP films are technically recyclable, the infrastructure for recycling these materials is limited, particularly in regions of the United States. Incineration is another option, which generates some energy but produces emissions in the process (PlasticsEurope, 2021).

4. Assessing the Carbon Footprint of OPP Film in Cartons

The carbon footprint associated with OPP films in cartons can be assessed through life cycle assessment (LCA), which evaluates environmental impacts in each phase of the product’s life. For example, the carbon output of an OPP film used in a carton for food packaging may involve calculations factoring in the weight of the film, energy consumed during its production, transportation distances, and estimated emissions based on disposal methods.

Studies indicate that switching to more sustainable packaging solutions can lead to a significant decrease in carbon emissions. For instance, converting from virgin OPP to recycled materials can reduce the carbon footprint by up to 30% on average (Duan et al., 2023).

5. Best Practices for Reducing Carbon Footprint in OPP Film Packaging

5.1 Material Selection

Opt for recycled or biobased content in packaging materials. Some manufacturers are now producing OPP films made with up to 30% recycled content, which can substantially lower emissions compared to virgin materials (Oliver, 2022).

5.2 Efficient Packaging Design

Implement minimalistic packaging designs that reduce material usage, thus lowering production and transport emissions. Lightweight cartons with efficient OPP film coverage also help minimize resource waste.

5.3 Enhance Recycling Programs

Businesses should engage in partnerships that support comprehensive recycling initiatives. By ensuring consumers have access to proper recycling channels, companies can greatly reduce the carbon footprint associated with OPP film waste.

6. FAQ

What is the carbon footprint of OPP film compared to other packaging materials?

OPP film generally has a lower carbon footprint relative to heavier packaging materials like glass or metal. However, it typically has a higher footprint than biodegradable alternatives. An LCA can provide tailored insights based on specific circumstances.

Can OPP films be recycled?

Yes, OPP films can be recycled, but the availability of recycling facilities varies. It is essential for businesses to invest in programs that facilitate proper recycling pathways to maximize the environmental benefits.

What steps can businesses take to lower their carbon emissions?

Businesses can reduce their carbon emissions by selecting sustainable materials, optimizing their supply chains, adopting renewable energy sources in production, and promoting consumer education around recycling practices.

7. Conclusion

The carbon footprint on OPP film in cartons is a crucial aspect of sustainable packaging practices. With the increasing emphasis on environmental responsibility, it is essential for businesses to evaluate their packaging choices thoroughly. By adopting innovative strategies, understanding their carbon impacts, and actively participating in recycling initiatives, companies can significantly contribute to a reduction in greenhouse gas emissions and foster a more sustainable future.