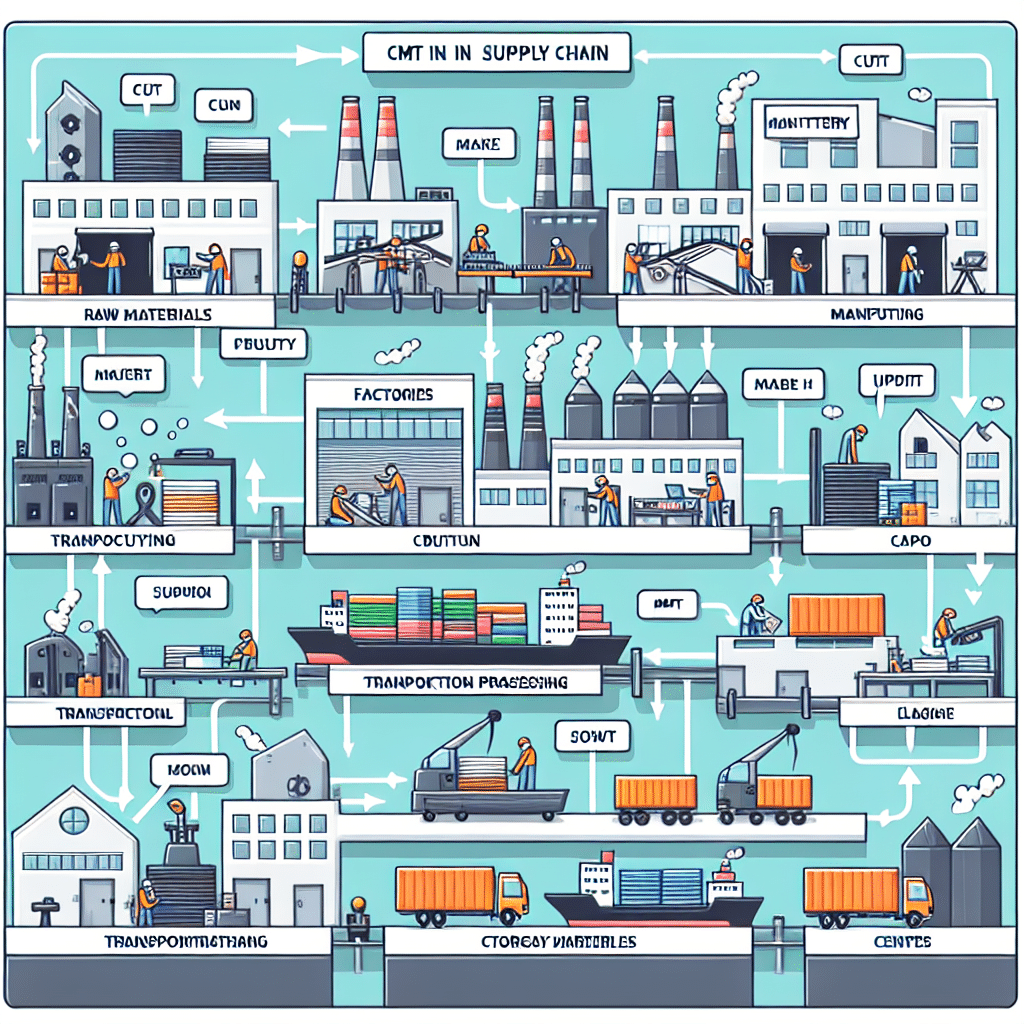

What is CMT in Supply Chain? CMT, or Cut-Make-Trim, is a manufacturing term widely used in the apparel and textile industries, referring to the production and assembly process of garments. CMT encompasses three key steps: cutting the fabric, making it into garments by sewing, and adding the finishing touches or trims. This method allows brands to outsource production to specialized manufacturers, enabling them to focus on design, marketing, and sales while leveraging the expertise of manufacturers. By utilizing CMT services, companies can optimize their supply chains, reduce costs, and enhance production efficiency. This process is pivotal for brands seeking to maintain competitiveness in a rapidly evolving market, allowing for flexibility and adaptability in their supply chain operations, which is crucial for meeting consumer demand.

Understanding the CMT Process

To fully grasp the concept of CMT in the supply chain, it’s essential to explore the various stages involved in this process:

1. Cutting

The cutting stage involves preparing and cutting the fabric according to specified patterns and sizes. This step is crucial as it directly impacts the material waste and the quality of the final product. Accurate cutting ensures that the subsequent sewing stage is efficient and that the fit of the garment meets the design specifications.

2. Making

The making phase refers to the assembly of the garment through sewing. Skilled labor is required to piece together the cut fabric using various stitching techniques. Quality control at this stage is vital, as any errors can lead to defects in the final product. Ensuring that sewing equipment is precisely calibrated can significantly affect production outcomes.

3. Trimming

The trimming process includes adding finishes such as labels, buttons, zippers, and other embellishments. This step elevates the aesthetic appeal of the garment and ensures that it meets market standards. Attention to detail in trims can differentiate a brand’s product in a competitive market.

Benefits of CMT in Supply Chain Management

Utilizing CMT services in supply chain management offers several advantages:

1. Cost Efficiency

Partnering with CMT manufacturers can reduce overhead costs associated with running in-house production. By outsourcing the labor-intensive aspects of garment production, brands can save on workforce management and facility maintenance.

2. Focus on Core Competencies

Outsourcing CMT allows fashion brands to concentrate on their core strengths, such as design and marketing, thereby enhancing their product offerings. This strategic focus can lead to improved business performance and customer satisfaction.

3. Flexibility and Scalability

CMT services provide brands the flexibility to scale their production up or down based on market demand. This adaptability is particularly vital in the fashion industry, where trends can change rapidly.

4. Global Supply Chain Access

Manufacturing partners who offer CMT services often have established supply chains and expertise in sourcing materials cost-effectively. This access enables brands to diversify their products and enter new markets.

Challenges Associated with CMT

While CMT has its advantages, there are also challenges that brands must consider:

1. Quality Control

Maintaining consistent quality can be difficult when production is outsourced. It requires robust quality assurance protocols to ensure that the final products meet the brand’s standards.

2. Communication Barriers

Working with manufacturers in different regions can sometimes lead to misunderstandings due to language or cultural differences. Effective communication is essential for a smooth workflow and successful project execution.

3. Lead Times

Outsourcing to CMT manufacturers can sometimes extend lead times, as coordination across various suppliers may be necessary. Planning and logistics play a critical role in supply chain efficiency.

4. Dependency on Suppliers

Over-reliance on CMT manufacturers can pose risks during disruptions in the supply chain, such as natural disasters or political instability. Brands must have contingency plans in place.

Best Practices for Implementing CMT in Supply Chains

To maximize the benefits of CMT in your supply chain, consider these best practices:

1. Select the Right Partner

Choosing a reliable CMT manufacturer is crucial. Look for partners with a proven track record, positive client testimonials, and relevant industry experience to ensure a successful collaboration.

2. Establish Clear Communication Channels

Implementing effective lines of communication between your team and the CMT provider can facilitate smooth operations. Regular updates and feedback help mitigate potential misunderstandings.

3. Invest in Quality Assurance

Implement thorough quality control measures at each stage of the CMT process. Regular audits and inspections will ensure the product meets your quality standards, thereby protecting your brand’s reputation.

4. Build Strong Relationships

Developing a positive working relationship with your CMT partners can lead to more productive collaborations. Building trust will often result in improved responsiveness and problem-solving capabilities.

Case Studies: Successful Implementation of CMT

Many leading brands have successfully incorporated CMT into their supply chain strategies:

1. Nike

Nike utilizes a global network of CMT partners to produce a significant portion of its activewear. The brand focuses on collaborating closely with its suppliers to ensure quality, reduce lead times, and innovate through feedback.

2. Zara

Zara’s rapid turnaround time in fashion production heavily relies on a well-structured CMT process. The company’s ability to respond quickly to design changes and consumer preferences demonstrates the flexibility that CMT offers.

Future Trends in CMT and Supply Chains

The landscape of the CMT approach is continuously evolving with technological advancements and market demands:

1. Sustainability

As consumer awareness of sustainability grows, CMT manufacturers are increasingly focusing on eco-friendly practices. This includes sourcing sustainable materials and minimizing waste during production processes.

2. Automation Technology

Integrating automation and AI-driven technologies within CMT processes can enhance efficiency and accuracy, leading to reduced costs and improved product quality.

3. Enhanced Data Analytics

Data analytics can provide insights into production trends and performance metrics, allowing brands to make informed decisions and optimize their supply chains further.

Frequently Asked Questions (FAQ)

What are the primary components of CMT?

The primary components of CMT include cutting fabric, sewing the pieces together, and adding finishes or trims to complete the garment.

How does CMT affect lead times?

CMT can sometimes extend lead times due to the need for coordination across various suppliers; however, with effective planning, brands can mitigate this issue.

Is CMT suitable for small businesses?

Yes, CMT can be advantageous for small businesses, allowing them to focus on design and marketing while outsourcing production to experienced partners.

How can brands ensure quality in CMT production?

Brands can ensure quality by implementing robust quality control measures at each stage of the CMT process and maintaining clear communication with their manufacturers.

Conclusion

The Cut-Make-Trim (CMT) approach serves as a pivotal component of supply chain management in the fashion industry. It not only facilitates efficient garment production but also allows brands to concentrate on their core competencies. By understanding the intricacies of the CMT process, including its benefits, challenges, and best practices, you can position your business for success in a highly competitive market. As the industry continues to evolve, embracing CMT alongside modern technologies and sustainable practices will be essential for future growth.