Introduction to FRP

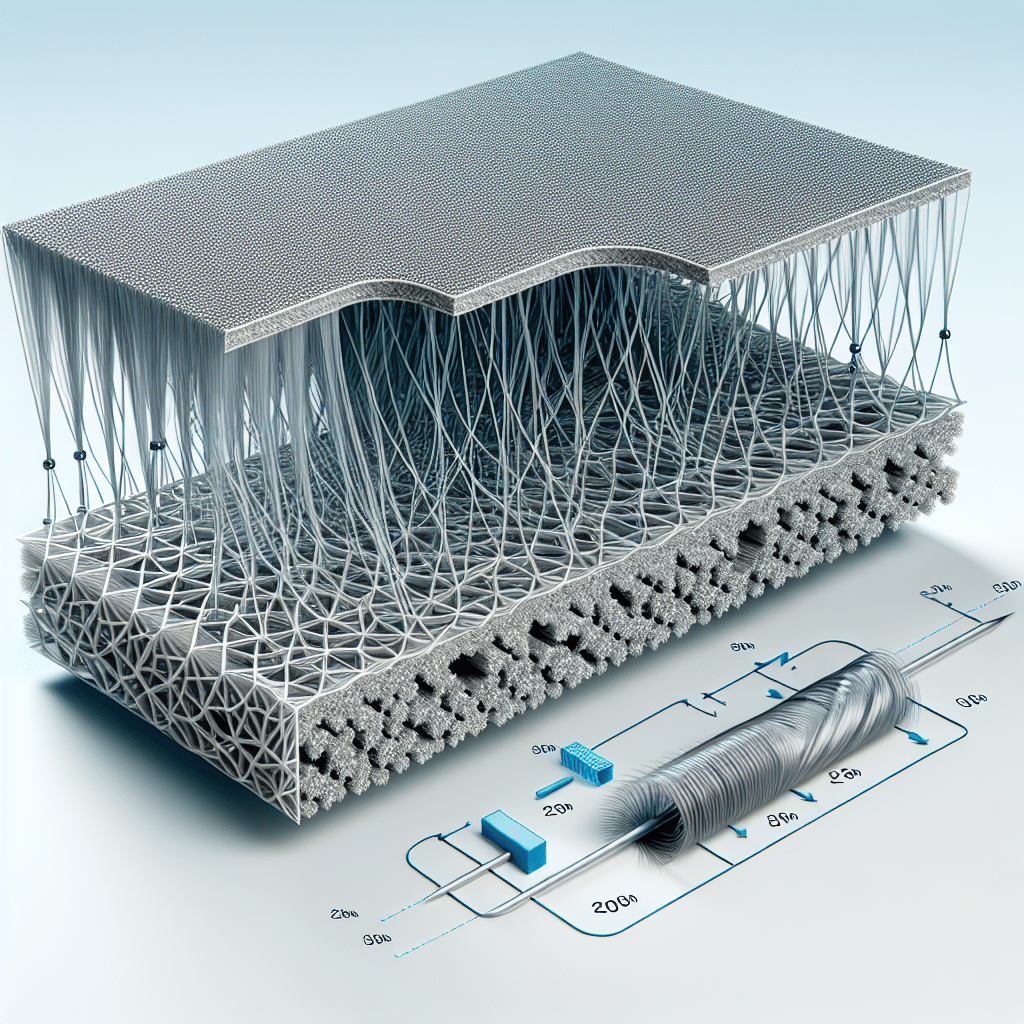

Fiber Reinforced Polymer (FRP) is a composite material consisting of a polymer matrix reinforced with fibers, primarily glass, carbon, or aramid. Combining the lightweight properties of polymers with the strength of reinforcing fibers makes FRP an ideal choice for various applications in construction, automotive, aerospace, and marine industries. Known for its corrosion resistance, high tensile strength, and flexibility, FRP is increasingly favored for structural and decorative elements. Its versatility allows easy shaping and molding into intricate designs, catering to modern design demands while ensuring the longevity and durability of structures.

Understanding FRP: A Deeper Dive

What is Fiber Reinforced Polymer (FRP)?

Fiber Reinforced Polymer (FRP) is advanced composite material that combines fibers, such as glass or carbon, with a polymer resin to create a strong, lightweight material. This innovative combination improves the mechanical properties of the polymer while providing enhanced strength, rigidity, and durability. The result is a material that can outperform traditional construction materials like steel and concrete in specific applications.

The Components of FRP

1. Fibers

Fibers play a crucial role in the effectiveness of FRPs. The commonly used fibers are:

- Glass Fibers: Affordable and widely used, glass fibers offer good mechanical properties and resistance to environmental factors.

- Carbon Fibers: Known for their exceptional strength-to-weight ratio, carbon fibers are often used in applications requiring high performance.

- Aramid Fibers: These fibers, including Kevlar, provide excellent tensile strength and are typically used in bulletproof materials and other high-stress applications.

2. Polymer Resin

The polymer resin matrix binds the fibers together and contributes to the material’s properties. There are several types of resin used in FRP, including:

- Polyester Resins: Cost-effective and suitable for various applications.

- Epoxy Resins: Offer superior adhesive properties, chemical resistance, and mechanical strength.

- Vinyl Ester Resins: Provide improved corrosion resistance and strength compared to traditional polyester resins.

How FRP Works

The principle behind FRP relies on the synergistic effect of the fibers and the resin. The fibers effectively handle tensile loads, while the resin imparts compressive strength. When forces are applied to the composite, the fibers bear the brunt of the load, while the polymer maintains the shape and integrity of the structure.

Applications of FRP

1. Construction Industry

In construction, FRP is commonly used for:

- Reinforcement of concrete structures: FRP bars are used to enhance the tensile capacity of concrete, extending its lifespan and durability.

- Bridge components: Due to its lightweight nature, FRP helps reduce the load on bridges while providing excellent support.

- Facades and interior finishes: FRP can be molded into various shapes, making it ideal for intricate architectural designs.

2. Automotive Industry

Automobile manufacturers utilize FRP in:

- Body panels: Lightweight FRP reduces vehicle weight, thus enhancing fuel efficiency and performance.

- Interior components: FRP is used for creating dashboards and other elements where aesthetics and functionality are essential.

3. Aerospace Industry

In aerospace, FRP is favored for:

- Aircraft structures: The lightweight properties of FRP contribute to enhanced fuel efficiency and reduced operational costs.

- Components in spacecraft: FRP is used in parts where weight reduction is crucial without compromising strength.

4. Marine Applications

Due to its corrosion resistance, FRP is widely used in marine applications like:

- Boat hulls: FRP boats offer lightweight and durable options for sailors.

- Marine infrastructure: FRP is utilized in docks and piers, where exposure to water demands materials that stand up to harsh conditions.

Benefits of Using FRP

1. Lightweight

One of the primary advantages of FRP is its lightweight profile compared to traditional materials, making it easier to handle and transport.

2. Corrosion Resistance

The inherent resistance to corrosion ensures that structures made of FRP last longer, requiring less maintenance and replacement.

3. High Strength-to-Weight Ratio

FRP offers a remarkable strength-to-weight ratio, making it ideal for applications where both strength and weight are critical factors.

4. Design Flexibility

FRP can be molded into various shapes and sizes, allowing designers significant creative freedom.

Challenges and Counterarguments

1. Cost Considerations

Although the initial cost of FRP can be higher than traditional materials, the long-term durability and reduced maintenance can offset these costs. It’s crucial to conduct a life-cycle cost analysis to understand its value fully.

2. Installation Expertise

The installation of FRP components requires specialized knowledge and skills, which might limit its use in some areas. Investing in proper training and certified professionals can alleviate these concerns.

3. Environmental Impact

While FRP materials provide numerous benefits, concerns about their recyclability and environmental impact arise. However, advancements in recycling technologies are being developed to tackle these issues.

Future of FRP

As industries globally focus on sustainability and cost-efficiency, the future of FRP looks promising. Research is ongoing into improving recyclability, reducing manufacturing costs, and expanding its applications across new markets. Innovations in composite materials will likely integrate bio-based resins, making FRP even more environmentally friendly.

Frequently Asked Questions (FAQ)

What are the main types of FRP?

The primary types of FRP include Glass Fiber Reinforced Polymer (GFRP), Carbon Fiber Reinforced Polymer (CFRP), and Aramid Fiber Reinforced Polymer (AFRP), each having unique properties suited for different applications.

Is FRP fire-resistant?

FRP has good fire-resistance properties depending on the resin used. However, it is essential to consider specific fire ratings and standards when selecting FRP for applications where fire resistance is critical.

How long does FRP last?

The lifespan of FRP can vary significantly based on the environment and application, with many FRP products lasting 20-50 years or more when properly maintained.

Can FRP be recycled?

Yes, though recycling FRP is more complex than traditional materials. Enhanced recycling methods are being researched to facilitate a more sustainable approach to FRP disposal and reuse.

Where can I use FRP in my construction project?

FRP can be utilized in various aspects of construction, including reinforcements in concrete, architectural facades, bridges, and structural components due to its lightweight and durable nature.