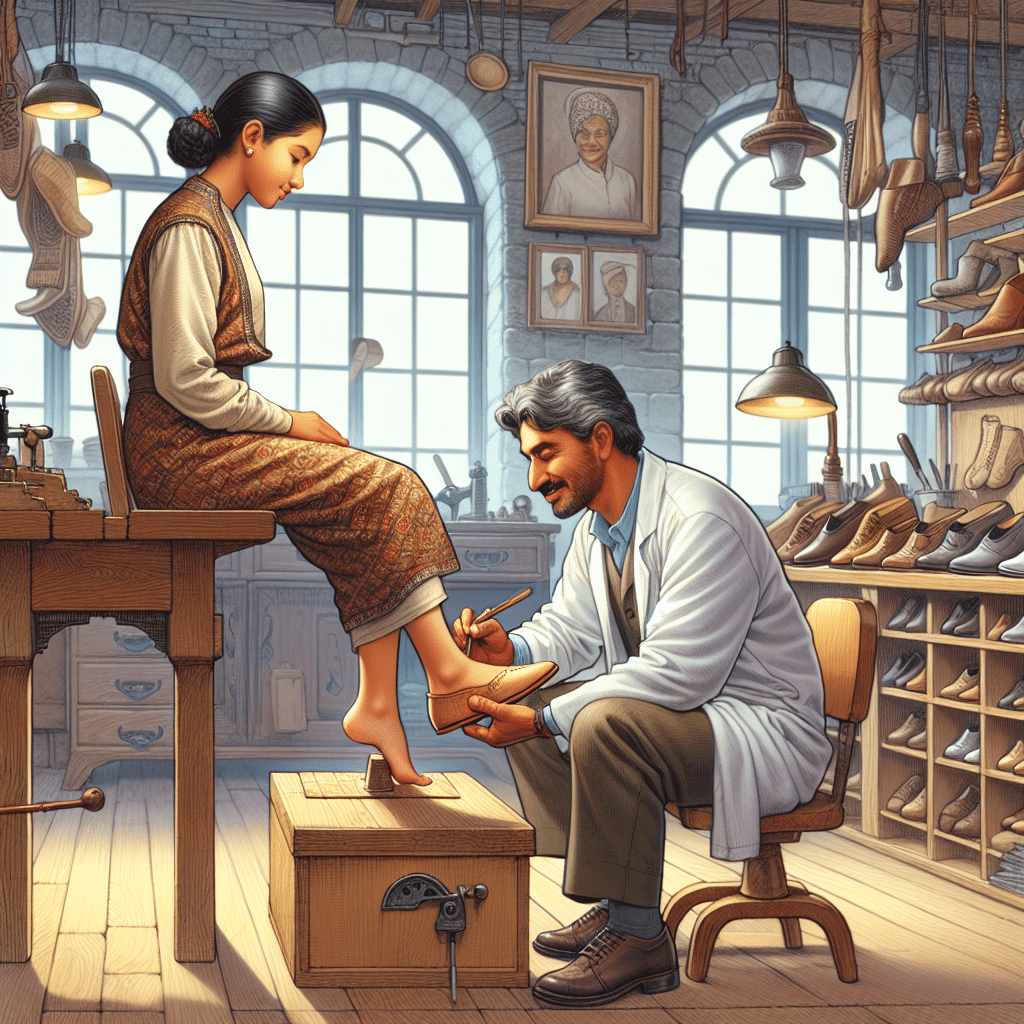

Last sizing is a crucial aspect in the footwear manufacturing process, referring specifically to the measurement and shaping of a shoe’s last—the mold onto which the shoe is constructed. This process ensures that the shoe fits comfortably without sacrificing style or function. In essence, last sizing involves selecting or creating lasts that correspond with the intended foot shape, size, and biomechanical needs, ultimately influencing user satisfaction and performance. Different shoe types—such as athletic, formal, and casual footwear—may utilize varied last sizes and shapes to meet diverse consumer preferences, ergonomic requirements, and design specifications.

Accurate last sizing not only affects the comfort and fit of the shoe but also plays a vital role in consumer purchasing decisions and overall brand perception. As such, manufacturers pay close attention to sizing standards, utilizing advanced technologies and production techniques to create lasts that accurately reflect foot measurements. By understanding the fundamentals of last sizing, anyone interested in footwear design and production can appreciate its impact on shoe quality and consumer experience.

Understanding Last Sizing

Last sizing is an integral part of the footwear industry, where the last serves as the foundation upon which shoes are built. A last is a three-dimensional representation of a foot, designed to reflect the foot’s anatomical features. The process of last sizing can be divided into several stages, including measurement, design, selection, and application.

Measurement Techniques

The first step in last sizing is obtaining precise measurements for different foot shapes and sizes. Foot measurements are typically gathered through various methods:

- Manual Measurement: Using a Brannock device, trained professionals can accurately measure foot length and width.

- 3D Scanning: Advanced technologies employ 3D scanners to capture detailed foot shapes, allowing for better customization.

- Digital Foot Measurement: Mobile applications and software solutions can also assist in acquiring accurate measurements for broader accessibility.

Types of Lasts

There are several types of lasts used in shoe making, each serving different functional purposes:

- Straight Lasts: Used for shoes that require a symmetrical fit, ideal for wider feet.

- Curved Lasts: Designed for shoes with a more elegant silhouette, typically used in dress and formal footwear.

- Semi-Straight Lasts: A combination of both straight and curved characteristics, providing a versatile option for different shoe styles.

Creating a Last

The creation of a last involves various steps to ensure it meets both aesthetic and functional requirements:

- Material Selection: Lasts can be made from wood, plastic, or metal, with each material impacting the durability and weight of the last.

- Design Modeling: Using computer-aided design (CAD) software, manufacturers can create precise models of lasts that cater to diverse foot shapes.

- Prototyping: 3D printing technology allows for quick prototyping, enabling companies to test the fit and comfort of new lasts rapidly.

The Importance of Accurate Last Sizing

Accurate last sizing directly affects shoe fit, comfort, and performance. Here are several reasons why manufacturers at all levels prioritize this aspect:

- Consumer Satisfaction: Proper fit leads to happier customers, fostering brand loyalty and repeat purchases.

- Minimized Returns: By ensuring proper sizing, companies can significantly reduce the rate of returns due to poor fit.

- Improved Performance: Especially in athletic footwear, accurate last sizing can enhance the comfort and efficiency of the wearer, contributing to better athletic performance.

Trends in Last Sizing

The footwear industry has seen several trends that influence last sizing:

- Increased Customization: The demand for personalized footwear solutions has led to a rise in custom lasts tailored to individual foot shapes.

- Sustainability: With a growing emphasis on sustainability, manufacturers are innovating to use eco-friendly materials in last production.

- Technology Integration: Advancements in technology, such as 3D printing and AI modeling, are increasingly shaping the future of last sizing.

Counterarguments

While accurate last sizing is critical, some may argue that extreme focus on perfecting lasts can lead to increased production costs and longer lead times. However, the benefits of improved fit and customer satisfaction typically outweigh these challenges, providing long-term advantages for manufacturers. By investing in technology and research, companies can address these concerns effectively, thus creating added value for both themselves and their customers.

Conclusion

Understanding last sizing is essential for anyone involved in the footwear industry. From enhancing comfort and fit to influencing consumer satisfaction, this aspect of shoe manufacturing has far-reaching implications. As the industry continues to evolve, staying informed about developments in last sizing and the technologies that support it will be vital for success.

Frequently Asked Questions (FAQ)

1. What is footwear last sizing?

Footwear last sizing refers to the process of measuring and shaping a shoe’s last, which is the mold used to construct shoes. It plays a critical role in determining the comfort and fit of footwear.

2. Why is accurate last sizing important?

Accurate last sizing ensures better shoe fit, enhances wearability, reduces return rates, and contributes to overall customer satisfaction, ultimately impacting sales and brand reputation.

3. How can I measure my foot for best fit?

You can measure your foot using a Brannock device for length and width, or use 3D foot scanning technologies or digital apps for accurate measurements.

4. What types of lasts exist in shoe manufacturing?

There are various types of lasts, including straight, curved, and semi-straight lasts, each designed to optimize fit for different shoe styles and foot shapes.

5. How has technology influenced last sizing?

Technology has revolutionized last sizing through 3D modeling, scanning, and printing, enabling high customization and quicker prototyping, thus enhancing the shoe manufacturing process.