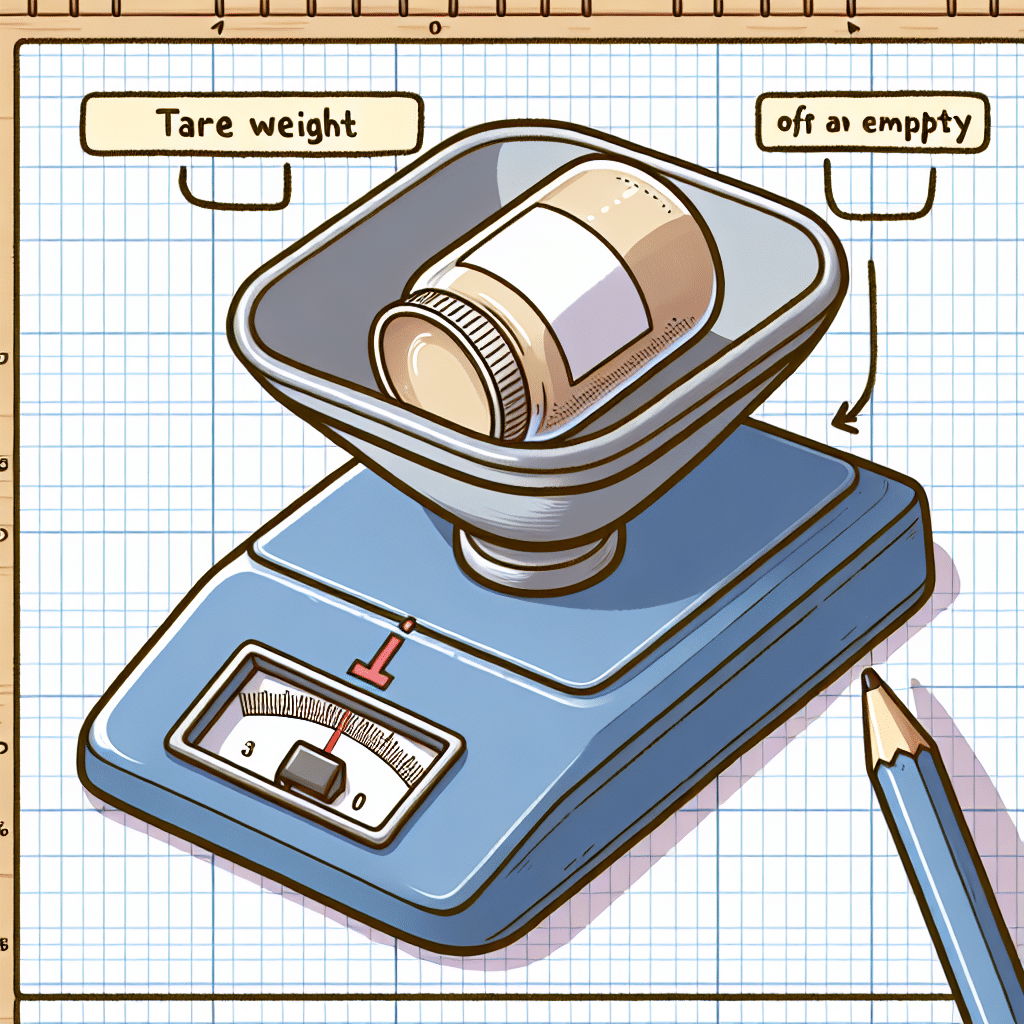

Tare weight refers to the weight of an empty container or vehicle without any cargo or additional materials. It is a critical concept in shipping, logistics, and various industries that require precise weight measurements. The tare weight is essential for determining the net weight of the goods being transported, as it allows businesses to differentiate between the weight of the packaging or container and the actual product weight. By subtracting the tare weight from the gross weight (the total weight of the packaging and contents), you can accurately find the net weight of the shipment, which is essential for pricing, compliance, and inventory management.

Understanding Tare Weight

Tare weight encompasses a variety of applications across different industries, playing a vital role in weight measurement, logistics, freight operations, and manufacturing. Understanding tare weight is essential for businesses and individuals involved in the weighing and distribution of goods, as it allows for accurate calculations that can affect pricing, shipping costs, and regulatory compliance.

The Importance of Tare Weight

Tare weight is crucial in everyday practices such as cooking, shipping, and commerce. Knowing the tare weight enables stakeholders to:

- Ensure Accurate Billing: Companies must charge customers based on the actual weight of the goods being sold or shipped. Accurate tare weight measurements prevent overcharging or undercharging.

- Comply with Regulations: Shipping industries must follow regulations set by governing bodies, like the Federal Motor Carrier Safety Administration (FMCSA) in the U.S., which can enforce strict weight regulations for transportation vehicles.

- Streamline Inventory Management: Accurate weight measurements help businesses manage inventory effectively, ensuring that they have enough product to meet demand without overstocking.

Calculating Tare Weight

Calculating tare weight can be straightforward. The general formula involves measuring both the gross weight and net weight:

Tare Weight = Gross Weight – Net Weight

For example, if a shipping container has a gross weight of 10,000 pounds and the net weight of the cargo inside is 8,000 pounds, the tare weight of the container is:

10,000 lbs – 8,000 lbs = 2,000 lbs

Common Applications of Tare Weight

Understanding tare weight’s application can vary across different contexts:

- Culinary Use: In cooking, tare weight allows chefs and bakers to create precise recipes by subtracting the weight of containers from the total weight of ingredients.

- Shipping and Freight: In logistics, tare weight helps determine shipping costs and avoids violations of weight restrictions.

- Manufacturing: In production environments, tare weight is used to ensure raw materials are accurately accounted for in batches, aiding in quality control.

Relationships with Other Weight Measurements

Tare weight is related to several other weight measurements:

- Gross Weight: The total weight, including cargo and container. It is essential for overarching assessments in logistics.

- Net Weight: The total weight of the cargo or the goods themselves, excluding any containers or packaging.

Understanding these relationships helps businesses and individuals navigate complex weight-related scenarios effectively.

Challenges and Considerations

Although tare weight is a vital metric, there are challenges associated with accurate measurement:

- Variability in Container Types: Different containers come with varying tare weights, complicating calculations if multiple container types are used.

- Dynamic Containers: Some containers may collect moisture or waste over time, adding weight that must be accounted for.

- Regulatory Compliance: Different regions may have varying regulations concerning weight limits, necessitating a consistent understanding and calculation of tare weight.

Best Practices for Managing Tare Weight

To maintain accuracy in tare weight, consider these best practices:

- Keep Updated Records: Maintain an updated inventory of tare weights for all containers to minimize errors in weight calculations.

- Prioritize Training: Ensure employees understand how to measure weight effectively, particularly with different types of scales.

- Regular Calibration: Calibration of weighing equipment should occur regularly to ensure accurate readings.

Frequently Asked Questions (FAQs)

1. What is the difference between tare weight and net weight?

The primary difference is that tare weight refers to the weight of the empty container, while net weight refers to the weight of the contents without any packaging.

2. How do I measure tare weight?

To measure tare weight, place an empty container on a scale, record its weight, and ensure that the scale is set to zero before adding any product.

3. Why is tare weight important for shipping?

Tare weight is crucial for shipping as it helps determine shipping costs, ensures compliance with transport regulations, and provides accurate weight assessments for invoicing.

4. Are there legal requirements for tare weight?

Yes, many jurisdictions have regulations on weight limits for vehicles and containers in shipping. Accurate tare weights help comply with these legal requirements.

5. Can tare weight change over time?

Yes, tare weight can change due to factors like container wear, moisture accumulation, or added materials, necessitating regular monitoring.

Conclusion

Tare weight is an essential measure that impacts various aspects of logistics, commerce, and everyday activities. By understanding and applying the measurement accurately, you can enhance operational efficiency, maintain regulatory compliance, and ensure precise billing. Whether you are managing inventories, engaging in cooking, or working in shipping, knowing the tare weight allows for informed decisions and improved accuracy.