Introduction

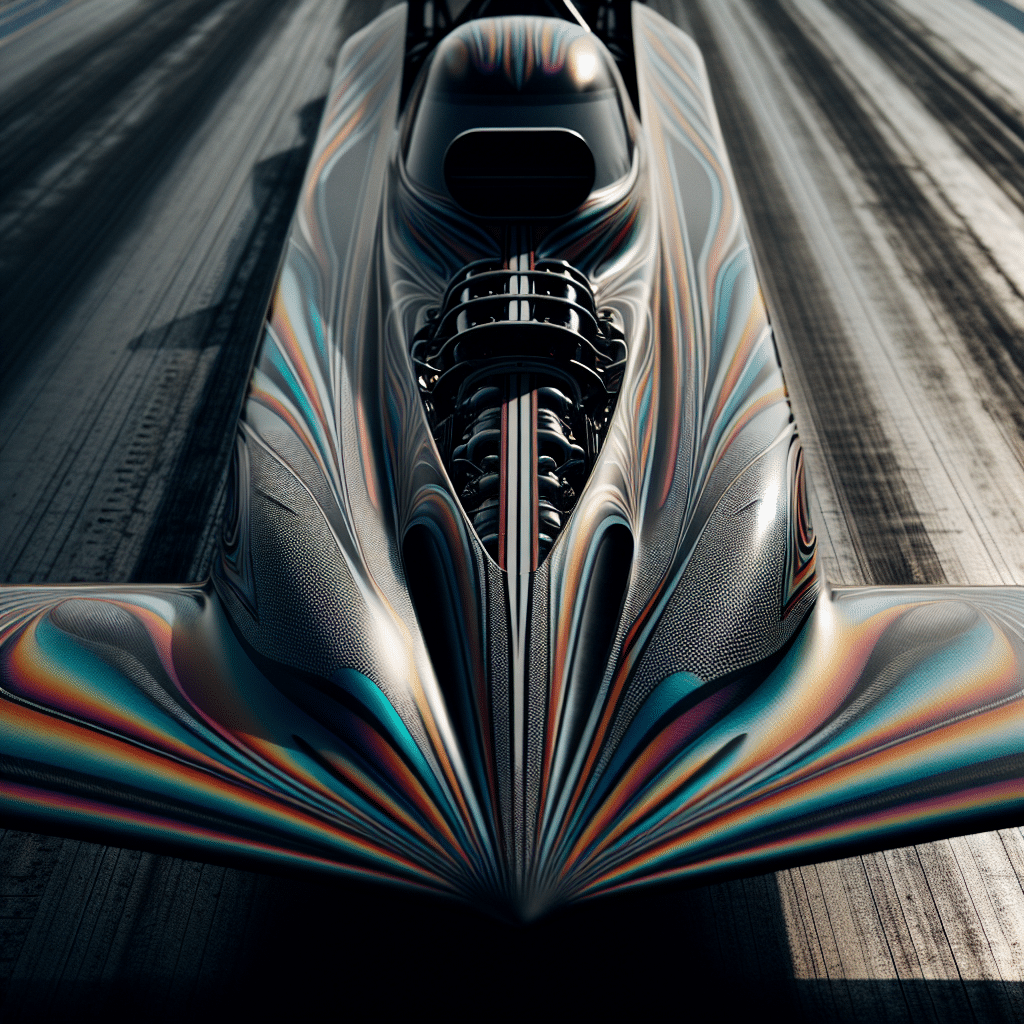

The cowl of a top fuel dragster is a critical aerodynamic component that plays an essential role in maintaining the car’s stability and enhancing its performance during high-speed runs. Located at the front of the vehicle, the cowl serves as a protective cover for the engine and is designed to streamline airflow, reducing drag and increasing downforce. By directing air into the engine’s supercharger while simultaneously managing the turbulent airflow around the vehicle, the cowl significantly contributes to the overall efficiency and power of the dragster. In high-octane racing scenarios, where every millisecond counts, the cowl’s design and aerodynamics can be the difference between winning and losing.

Understanding the Role of the Cowl

The cowl is more than just a cover; it is an integral part of top fuel dragster aerodynamics. Its shape and design are meticulously engineered to ensure optimal airflow management. Let’s break down the components contributing to its function:

Aerodynamic Design

The streamlined shape of the cowl minimizes air resistance, allowing the vehicle to slice through the air. The design often features specific contours and angles optimized through wind tunnel testing. This enables the dragster to achieve higher speeds by reducing drag, which is vital when competing at speeds exceeding 300 miles per hour.

Engine Cooling and Performance

While primarily aimed at aerodynamics, the cowl also aids in cooling the engine. A well-designed cowl ensures that sufficient airflow reaches the engine components, preventing overheating in intense racing conditions. It helps funnel cold air directly into the supercharger, fine-tuning the engine’s performance during critical moments of acceleration.

Structural Integrity

Additionally, the cowl contributes to the structural integrity of the dragster. As one piece of a larger system, it works with other body components to maintain rigidity and ensure the car withstands the significant forces experienced during a drag race. This aspect is crucial for driver safety and optimal performance.

How the Cowl Works in Conjunction with Other Components

To understand the full functionality of the cowl, it’s vital to see how it interacts with other parts of the dragster:

Supercharger Integration

The supercharger is a key component powered by the engine, increasing the amount of air entering the combustion chamber. The cowl directs air into the supercharger efficiently, maximizing the engine’s power output. This synergy between the cowl and supercharger is crucial for achieving the incredible horsepower demanded in top fuel drag racing.

Windshield and Cockpit Design

The cowl’s design also influences the interior setup of the dragster. The windshield is strategically placed to minimize aerodynamic drag while ensuring the driver has optimal visibility. The design ensures that the airflow is directed around the driver’s area, reducing lift that could affect handling.

Impact on Downforce

Downforce is essential in drag racing as it keeps the tires planted on the track. The cowl, when angled correctly, helps create a pressure differential that pulls the car toward the ground, enhancing tire grip and traction during rapid acceleration.

Materials and Technology Used in Cowl Construction

The materials used in the construction of a top fuel dragster’s cowl are sophisticated and chosen for their performance characteristics:

Composite Materials

The majority of top fuel dragsters utilize composite materials, such as carbon fiber and fiberglass, for their light weight and high strength. These materials can withstand the extreme forces encountered during a race while contributing to the aerodynamic efficiency of the cowl.

Advanced Manufacturing Techniques

Modern manufacturing techniques, including computer-aided design (CAD) and 3D printing, allow for precise shaping and modifications to the cowl. These advancements enable engineers to test and iterate designs rapidly, leading to improvements in aerodynamics and performance accuracy.

Best Practices for Cowl Maintenance

Maintaining the cowl is crucial to ensuring the dragster operates at peak performance:

Regular Inspections

Perform regular inspections to check for cracks, signs of wear, or any distortions that could alter its aerodynamic properties. Ensuring structural integrity is paramount for performance and safety.

Cleaning Techniques

Cleaning the cowl must be done with appropriate materials to avoid scratching or damaging the surface. Utilizing microfiber cloths and non-abrasive cleaners is advisable to maintain the cowl’s finish and aerodynamics.

Upgrades and Modifications

As technology advances, upgrading the cowl with new designs or materials can significantly improve performance. Consulting with aerodynamics engineers can help determine the most beneficial enhancements.

Common Misconceptions about the Cowl

Despite the importance of the cowl, several misconceptions exist regarding its purpose and function:

It’s Just for Aesthetics

Many believe that the cowl’s primary role is aesthetic appeal, but this is far from the truth. Its engineering is crucial for aerodynamics, performance, and safety.

All Cowls are the Same

Not all cowls are identical. Each design is tailored to specific racing conditions, engine configurations, and aerodynamics to achieve optimal performance.

Conclusion

The cowl of a top fuel dragster represents a sophisticated blend of engineering and design, pivotal to the car’s overall performance. By understanding its function, materials, and maintenance, you enhance your insight into the complex world of drag racing and the intricate components that contribute to a dragster’s extraordinary speed and power.

Frequently Asked Questions

What materials are commonly used in the construction of a dragster cowl?

Top fuel dragsters typically use composite materials like carbon fiber and fiberglass due to their lightweight properties and strength, which are essential for maintaining performance at high speeds.

How does the cowl affect the aerodynamics of a top fuel dragster?

The cowl’s design reduces aerodynamic drag and increases downforce, allowing the dragster to achieve higher speeds by ensuring stable airflow over the vehicle during races.

Why is regular maintenance of the cowl important?

Regular maintenance ensures the cowl remains structurally sound and aerodynamically efficient. Inspections for cracks and wear can prevent performance degradation and safety risks during races.

Can modifications to the cowl improve race performance?

Yes, modifications to the cowl can enhance aerodynamics and engine performance. Engaging with engineering experts can help identify beneficial modifications tailored to specific racing needs.

What are the common myths about the cowl in drag racing?

Common myths include the idea that cowls serve only aesthetic purposes and that all cowls are built the same. In reality, cowls are vital to performance, with designs tailored to specific racing conditions and vehicle specifics.