Introduction

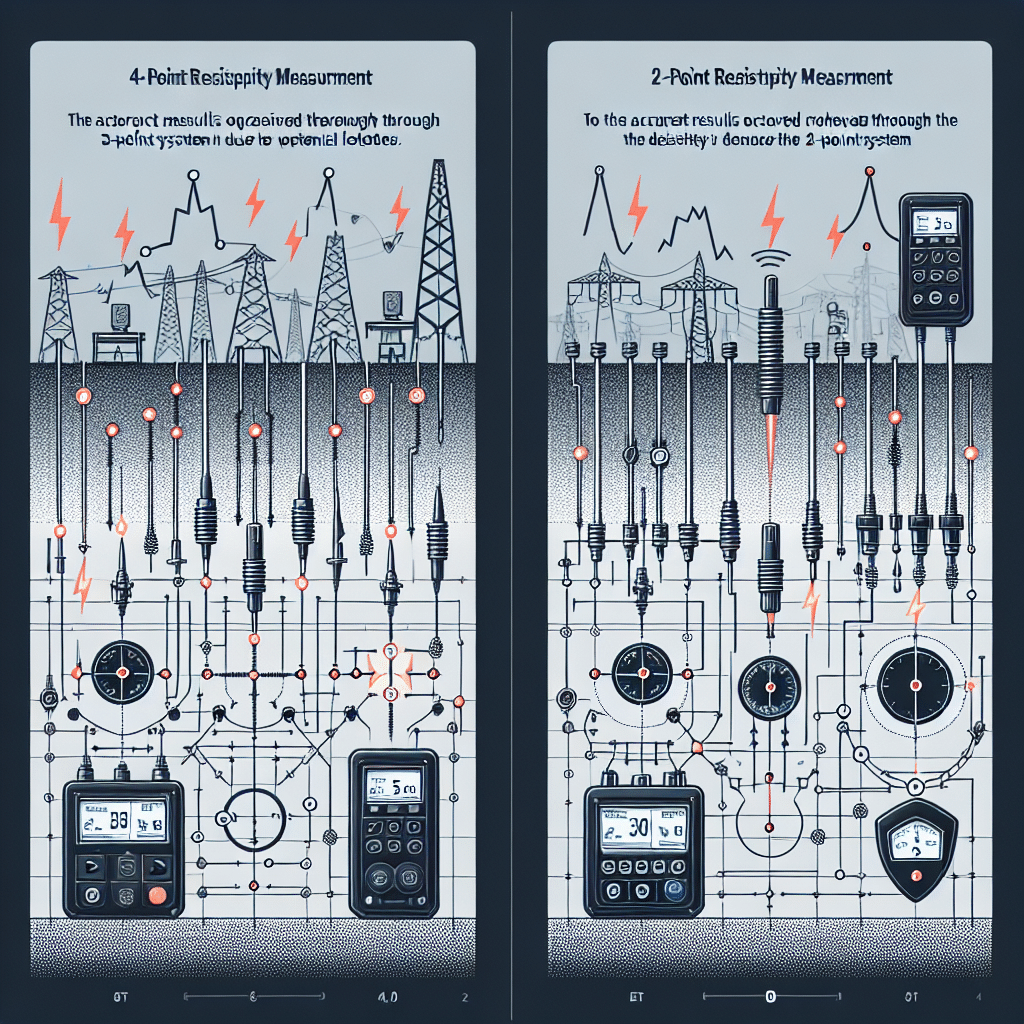

When assessing the electrical properties of materials, particularly in geophysical and engineering applications, resistivity measurements are pivotal. Two prevalent methods for measuring resistivity are the 2-point and 4-point techniques. The primary difference lies in the methodology and accuracy they offer. The 2-point resistivity method uses two electrodes to measure resistance directly, which can be influenced by contact resistance, making it less accurate for subsurface investigations. In contrast, the 4-point resistivity method utilizes four electrodes to separate the current-carrying and voltage-sensing measurements, thus minimizing the impact of contact resistance and providing more reliable data. This article delves deep into the technicalities, applications, advantages, and limitations of both techniques, allowing readers to understand the optimal scenarios for their use.

Understanding Resistivity

Resistivity is a fundamental property of materials that quantifies how strongly they resist current flow. It is characterized by the material’s ability to conduct electric current, influenced by factors like temperature, material structure, and impurity levels. The resistivity ((ρ)) of a material can be mathematically represented as:

(ρ = R cdot A / L)

where (R) is resistance, (A) is the cross-sectional area of the material, and (L) is the length of the conductive path.

2-Point Resistivity Method

The 2-point resistivity method, also known as the 2-electrode method, is the simplest way to measure the resistivity of a material. It involves placing two electrodes in direct contact with the material under investigation. A voltage is applied between the two pointers, and the resultant current is measured.

Procedure

The procedure can be summarized in the following steps:

- Insert two electrodes into the material.

- Apply a known voltage across the electrodes.

- Measure the resulting current.

Advantages

Some benefits of the 2-point method include:

- Simple setup and minimal equipment needed.

- Quick measurements can be made on-site.

- Useful for materials where quick assessments are needed.

Limitations

However, the 2-point method has notable drawbacks:

- It cannot accurately measure resistivity due to the influence of contact resistance.

- Results may vary significantly depending on electrode placement and connection quality.

- Less effective for uneven or porous materials where inhomogeneity affects readings.

4-Point Resistivity Method

The 4-point resistivity method, or the 4-electrode method, offers a more sophisticated approach to measuring resistivity. This technique separates the current-carrying and voltage-sensing electrodes to minimize the effects of contact resistance.

Procedure

The methodology is as follows:

- Place four electrodes linearly in the material.

- Apply a current through the outer two electrodes.

- Measure the voltage across the inner two electrodes.

Advantages

The 4-point method has several advantages:

- Minimized effects of contact resistance improve measurement accuracy.

- Offers more reliable data for research and engineering applications.

- Can be used for both homogeneous and heterogeneous materials.

Limitations

While the 4-point method is superior in many respects, it does come with drawbacks:

- More complex setup and requires specialized equipment.

- Takes longer to measure compared to 2-point method due to additional steps.

- Requires more care in electrode placement to maintain accuracy.

Comparison of 2-Point and 4-Point Resistivity Methods

| Feature | 2-Point Resistivity | 4-Point Resistivity |

|---|---|---|

| Setup Complexity | Simple | Complex |

| Measurement Accuracy | Lower | Higher |

| Time Required | Quick | Longer |

| Equipment Needed | Minimal | More specialized |

| Influence of Contact Resistance | High | Low |

| Best Application | Preliminary assessments | Detailed studies and research |

Applications of Resistivity Measurements

Both methods have widespread applications in various fields such as:

- Geophysics: To assess subsurface materials in mining or oil and gas exploration.

- Civil Engineering: To evaluate soil properties for foundation design and stability assessments.

- Environmental Studies: For detecting contaminants in soil and groundwater.

- Electrical Engineering: In testing materials for conductivity and component reliability.

Challenges and Considerations

When selecting between 2-point and 4-point resistivity methods, several challenges and considerations surface:

- Field Conditions: Moist or uneven soil can affect measurements; thus, site evaluation is crucial.

- Material Homogeneity: For heterogeneous materials, the 4-point method yields more reliable readings.

- Budget Constraints: The initial setup for the 4-point method can be pricier due to specialized equipment.

Future Trends in Resistivity Measurement

As technology evolves, resistivity measurement techniques are increasingly adopting advancements such as:

- Digital Measurement Systems: Improved accuracy and data collection capabilities.

- Wireless Technology: Facilitating remote measurements and data transmission.

- Integration with Machine Learning: Enhancing data analysis and interpretation.

FAQ

1. What is 4-point resistivity used for?

4-point resistivity is primarily used for obtaining accurate resistivity measurements in materials and soils, minimizing the influence of contact resistance and making it ideal for detailed geophysical surveys and engineering applications.

2. Can the 2-point method be used for any application?

While the 2-point method is applicable in various scenarios, it is best suited for preliminary assessments or situations where high accuracy is not critical, such as quick field tests.

3. How can I improve the accuracy of 2-point measurements?

To enhance the accuracy of 2-point measurements, ensure good electrode contact, maintain consistent measurements in similar conditions, and minimize environmental interference.

4. Are there specific materials where one method performs significantly better?

Yes, the 4-point method generally outperforms the 2-point method in heterogeneous or porous materials where contact resistance may skew results. Conversely, the 2-point method may suffice for homogeneous materials where resistivity is uniform.

Conclusion

In summary, the choice between 2-point and 4-point resistivity methods pivots on the specific requirements of your project. While the 2-point method offers simplicity and speed for basic assessments, the 4-point method delivers higher accuracy and reliability, crucial in engineering, geophysical, and environmental applications. Ultimately, aligning the measurement technique to your project’s needs, constraints, and objectives will lead to more informed decision-making and effective outcomes.