Introduction

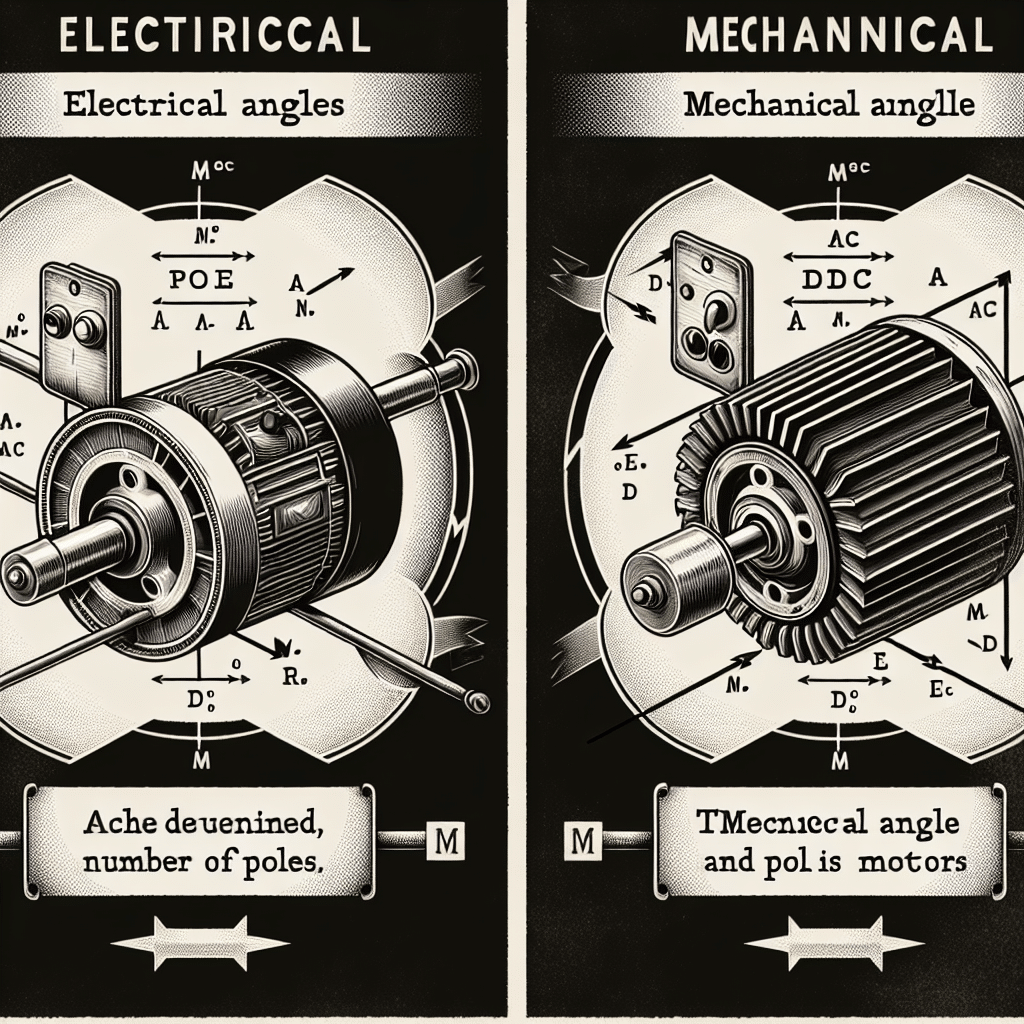

The difference between electrical angle and mechanical angle is critical in understanding the functionality of electric machines, particularly in motors and generators. The electrical angle refers to the angle in terms of electromagnetic rotation, while the mechanical angle represents the actual rotational position of the motor’s rotor. Specifically, the electrical angle is often measured in degrees as a function of how many electrical cycles have occurred, whereas the mechanical angle is based on the physical rotations of the rotor itself. The distinction is vital for applications involving torque generation and control in both brushless and brushed DC motors.

Understanding Angles in Electrical Machines

What is Electrical Angle?

The electrical angle is defined in relation to the electrical cycles of the supply voltage in an electrical machine. In a synchronous machine, for instance, one complete electrical cycle corresponds to one complete revolution of the stator’s magnetic field. This relationship is crucial for operating conditions, especially for the synchronization of controls and management of reactive power. The electrical angle is typically denoted in degrees or radians and is significant when analyzing the phase relationship between voltage and current.

What is Mechanical Angle?

The mechanical angle refers to the actual angular displacement of a rotating part in a machine. It is measured concerning the physical position of components like rotors or gears. The mechanical angle is straightforward — if the rotor has completed one full turn, the mechanical angle would be 360 degrees or 2π radians. This angle is essential for torque and speed calculations and ensures proper hardware interfacing in applications where physical motion translates directly to output work.

The Relationship Between Electrical and Mechanical Angles

To comprehend the difference, it is important to establish their relationship. In an electrical machine, the electrical angle ((theta_e)) can be calculated from the mechanical angle ((theta_m)) using the formula:

[theta_e = p times theta_m]

Where (p) represents the number of pole pairs in the machine. This shows that for machines with multiple poles, the electrical angle will advance more rapidly than the mechanical angle. This equation is pertinent in brushless DC motors, induction motors, and synchronous motors, where synchronizing the two angles is crucial for efficient operation.

Applications of Electrical and Mechanical Angles

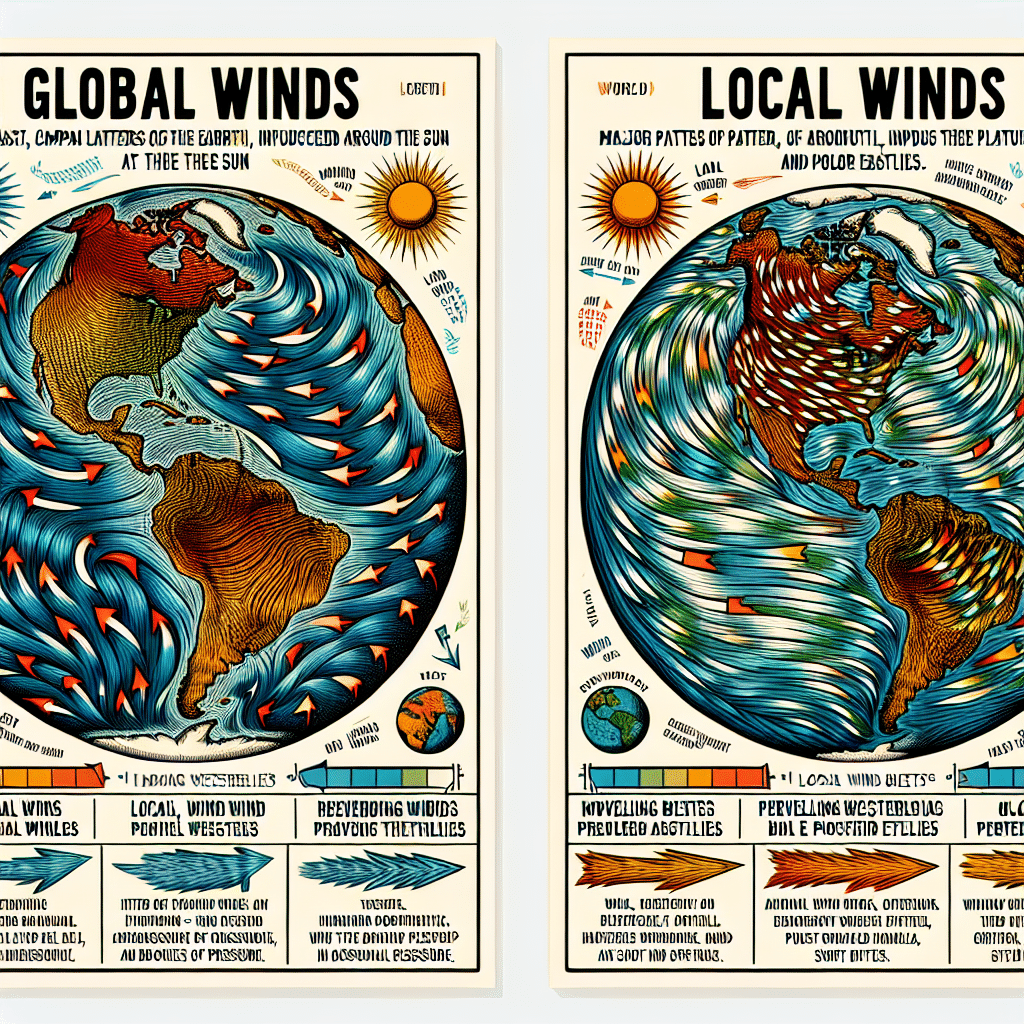

Motor Control Strategies

In the context of control systems, both angles are crucial for developing efficient algorithms. Vector control, or field-oriented control (FOC), leverages the difference between the two angles to optimize motor performance. By controlling the electrical angle, it is possible to enhance efficiency across varying speeds and loads, thus maximizing the operational capacity of electric motors.

Feedback Systems

Feedback systems, particularly in servo motors and robotic applications, require precise measurements of both electrical and mechanical angles to ensure accurate motion control. These measurements enable fine-tuning of position, with the electrical angle helping predict torque generation and the mechanical angle helping achieve the desired physical position.

Counterarguments: The Complexity of the Relationship

While the distinction between electrical and mechanical angles is clear, some argue the simplicity of their relationship can be misleading. Variability in motor designs, load conditions, and real-world physical properties can complicate the ideal projections offered by the electrical-mechanical angle relationship. For example, in non-synchronous motors, slip creates a discrepancy that complicates the expected interactions between the mechanical and electrical angles.

Frequently Asked Questions (FAQ)

1. Why is the electrical angle important in motor control?

The electrical angle is crucial because it helps synchronize the motor’s magnetic field with the rotor position, optimizing performance, torque production, and efficiency during operation.

2. How do you calculate the electrical angle?

The electrical angle can be calculated using the formula (theta_e = p times theta_m), where (p) is the number of pole pairs and (theta_m) is the mechanical angle in degrees or radians.

3. Can you have a mechanical angle without an electrical angle?

In the context of electric machines, mechanical angles are always present as they account for the physical position of moving parts. However, the electrical angle concept may not apply directly in purely mechanical systems.

4. How do slip and load affect the relationship between electrical and mechanical angles?

In induction motors, slip causes the rotor to lag behind the rotating magnetic field, leading to differences between mechanical and electrical angles affecting performance characteristics like torque and speed.

5. What role do sensors play in measuring these angles?

Sensors such as encoders and resolvers can accurately measure mechanical angles, while Hall effect sensors and other electrical measurement devices provide data for electrical angles, ensuring optimized motor control and feedback.

Conclusion

Understanding the differences between electrical and mechanical angles is vital for professionals in electrical engineering, particularly in design and control of electric motor systems. The implications of these angles extend beyond theoretical constructs into practical applications that define efficiency, control, and performance in electric machines. Equipped with this knowledge, you can inform design choices, enhance system performance, and navigate the complexities of motor control more effectively.