Introduction

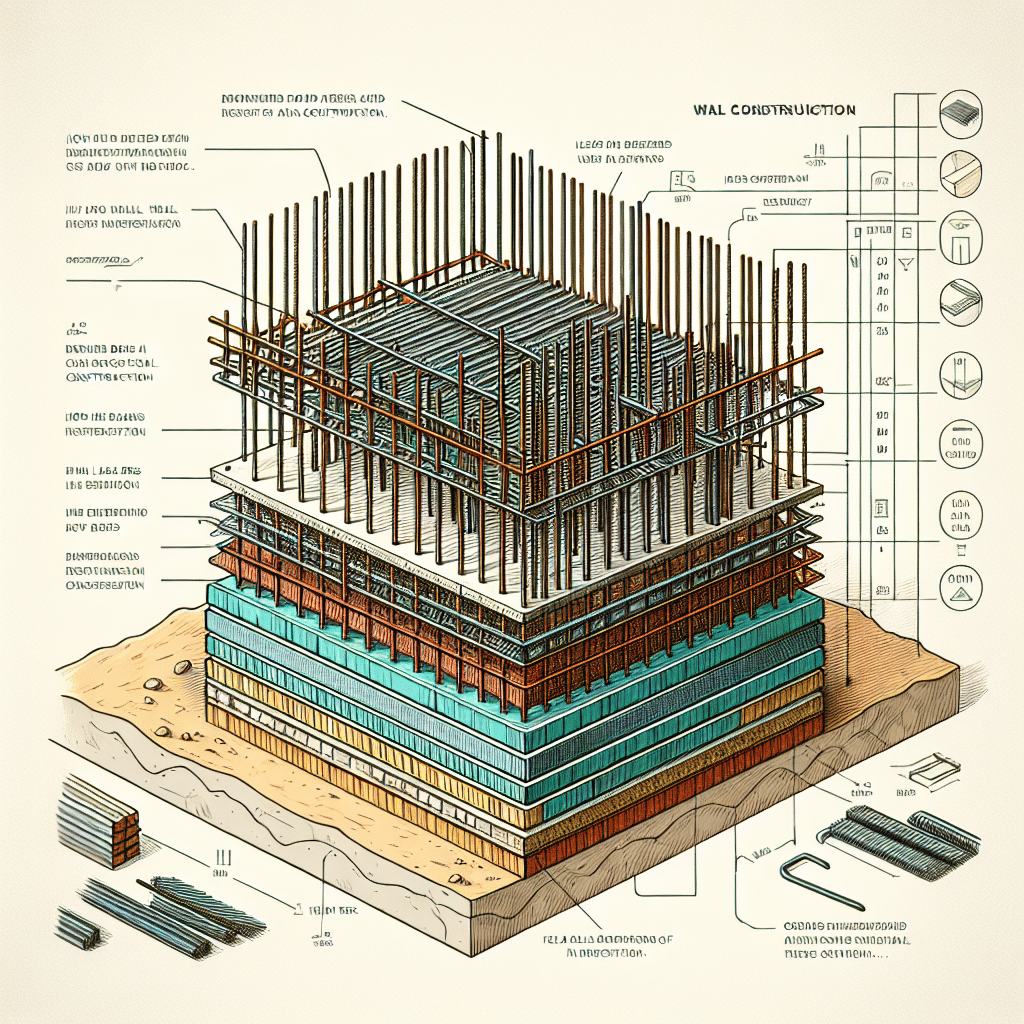

When it comes to constructing walls, especially in residential and commercial buildings, the most commonly used iron is rebar, or reinforcing bar. Rebar is typically made from steel and is crucial in providing structural support to concrete walls, enhancing their tensile strength. It prevents cracking and helps stabilize the integrity of the walls during events such as earthquakes and extreme weather. In the United States, the use of rebar is standardized under the American Society for Testing and Materials (ASTM) guidelines, ensuring compliance with safety and performance requirements. Understanding the role of rebar in wall construction is essential for both builders and property owners, as it directly affects the durability and longevity of any structure.

Types of Iron Used in Walls

1. Reinforcing Bar (Rebar)

Rebar is the most prevalent iron used in wall construction, particularly in concrete structures. Typically composed of carbon steel, it provides the necessary strength to counteract tensile forces that concrete alone cannot handle. Rebar is available in various grades, sizes, and coatings to meet different construction requirements. Its ribbed surface allows for better bonding with concrete, enhancing overall structural integrity.

2. Mild Steel

Mild steel is another form of iron that is sometimes employed in wall structures, particularly for non-load-bearing applications. It is malleable and easily workable, making it suitable for creating custom frame structures and decorative elements. However, it is not as effective as rebar in providing tensile strength, limiting its usage in structural applications.

3. Wire Mesh

Wire mesh, often made from welded or woven steel wires, is frequently used to reinforce walls and slabs in residential and commercial buildings. It provides a surface for concrete to bond with and helps distribute loads across a wider area. While not a substitute for rebar in major structural applications, it serves as an economical reinforcement method in situations where lower tensile strength is required.

Properties of Rebar

Corrosion Resistance

The longevity of a concrete structure heavily relies on the corrosion resistance of rebar. Epoxy-coated rebar and stainless steel rebar are available options that enhance resistance to environmental elements, making them suitable for use in areas prone to moisture, salt, or chemicals.

Load-Bearing Capacity

The load-bearing capacity of rebar is measured in terms of yield strength, with common grades ranging from 40,000 psi to over 75,000 psi. Choosing the correct grade is crucial for ensuring that walls can carry the imposed loads without failure.

Installation Considerations

Spacing and Placement

Proper spacing and placement of rebar are critical to maximizing its effectiveness in wall construction. Typically, rebar should be placed in accordance with local building codes and engineering calculations. It is often positioned vertically and horizontally within the concrete to form a grid, effectively resisting tension and shear forces.

Concrete Cover

Concrete cover refers to the layer of concrete that surrounds the rebar. Adequate cover is necessary to protect the metal from corrosion and to prevent concrete spalling. Building codes usually specify minimum cover requirements depending on the exposure conditions.

Best Practices for Using Rebar

1. Correct Sizing

Choose the appropriate size and grade of rebar for the specific application as per the structural design requirements. Consulting with a structural engineer can ensure compliance with safety standards and performance expectations.

2. Quality Assurance

Utilizing high-quality rebar is essential. Ensure the iron is sourced from reputable suppliers who adhere to industry standards and specifications outlined by ASTM.

3. Proper Handling

Handle and store rebar correctly to prevent damage or deformation. Keep it dry and free from rust before application, ensuring it performs to its optimal capacity.

Conclusion

The most commonly used iron in wall construction is rebar, which effectively enhances the structural integrity of concrete structures. Understanding the types, properties, and best practices associated with rebar is essential for builders and homeowners alike, ensuring the durability and safety of walls in their properties.

Frequently Asked Questions (FAQ)

What is rebar?

Rebar, or reinforcing bar, is a steel bar used to reinforce concrete and is crucial for maintaining the structural integrity of walls and other concrete structures.

How does rebar improve wall strength?

Rebar improves wall strength by providing tensile reinforcement that concrete lacks. It helps in evenly distributing loads and preventing cracks or failures under stress.

What are the different grades of rebar available?

Rebar comes in various grades, typically ranging from Grade 40 to Grade 75, which refers to the yield strength of the steel. Higher grades provide greater tensile strength and are used for more demanding constructions.

Are there alternatives to rebar in wall construction?

While rebar is the most common reinforcement, alternatives like fiber reinforcement, wire mesh, and composite materials can be used depending on specific project requirements and conditions.

How do I know the right size of rebar for my wall?

Choosing the right size of rebar involves consulting with a structural engineer or adhering to local building codes and standards based on the wall’s height, load, and exposure conditions.