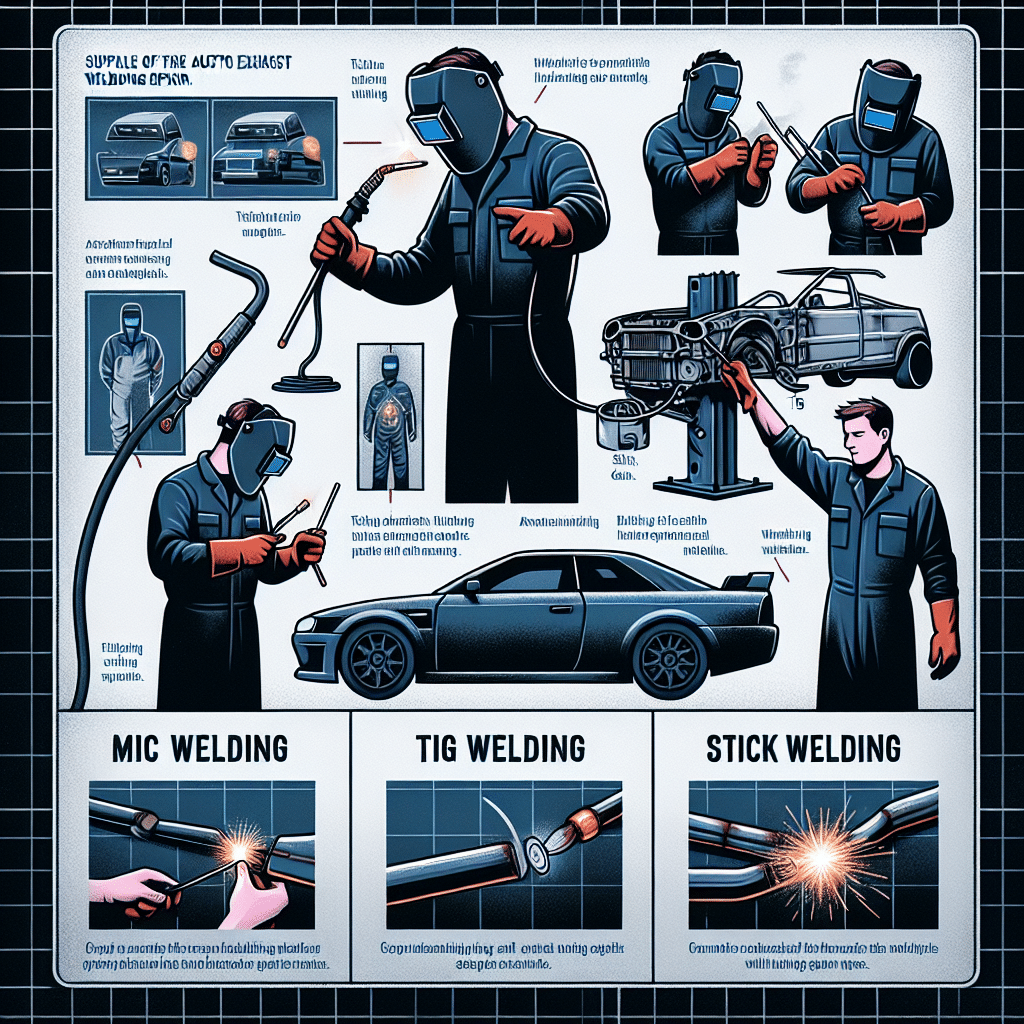

When it comes to welding auto exhaust systems, choosing the right type of welder is crucial for achieving strong, durable joints. The best option for automotive exhaust welding is typically a MIG (Metal Inert Gas) welder. MIG welding is favored for its ease of use, speed, and capability to produce clean, strong welds on thin materials like exhaust pipes. It provides versatility across various metal types, including mild steel and stainless steel, commonly found in exhaust components. However, TIG (Tungsten Inert Gas) welding can also be beneficial for precision work or when working with stainless steel due to its superior finish and control. Properly matching the welder to the material and the specific job requirements ensures longevity and quality in your exhaust system repairs or modifications.

Understanding Welding for Auto Exhaust Systems

Welding is a critical skill in automotive repair, particularly when dealing with exhaust systems that require durable and corrosion-resistant joints. Your choice of welder plays a crucial role in the task’s success. Different welding types produce varying effects on metal, so understanding their strengths and weaknesses can make all the difference.

MIG Welding: The Best Choice for Auto Exhaust

MIG welding is often regarded as the best method for welding automotive exhaust systems. This method uses a consumable wire electrode, fed through a welding gun, that creates an arc between the wire and the workpiece, melting both to form a weld. Below are the reasons why MIG welding is the preferred choice:

Advantages of MIG Welding

- Ease of Use: MIG welding is generally easier for beginners to learn, making it accessible for automotive enthusiasts or hobbyists.

- Speed: This method is typically faster than others, allowing for quicker repairs and modifications, a vital factor in automotive work.

- Clean Welds: MIG welding produces less spatter compared to other methods, making subsequent cleaning easier and providing a smooth finish.

- Versatility: A MIG welder can handle various metals (including mild steel and stainless steel), which is especially useful in exhaust work.

- Control: Offers excellent control over the welding process, which is essential when working with the often-thin materials found in exhaust systems.

TIG Welding: For Precision Work

While MIG welding is often the go-to, TIG welding has its advantages for specific applications within auto exhaust work. Unlike MIG, TIG welding uses a non-consumable tungsten electrode, which allows for greater control and finesse in welding:

When to Use TIG Welding

- Stainless Steel Applications: If working extensively with stainless steel exhaust systems, TIG welding provides a cleaner finish and better control over heat, reducing the risk of warping.

- Thin Material Welding: TIG is suited for thinner materials, where precise control can prevent burn-through.

- Weld Quality: It produces high-quality welds with minimal distortion and a beautiful appearance, crucial in visible areas of an exhaust system.

Considerations for Choosing a Welder

Aside from the welding technique, several factors come into play when selecting the best welder for auto exhaust systems:

1. Material Type

Understand the materials you will be welding. Different metals may require different approaches. For example, stainless steel components may benefit more from a TIG approach, while mild steel exhaust pipes typically align with MIG methods.

2. Thickness of Material

Thicker materials are often better suited to MIG welding due to its ability to produce stronger welds quickly, while thinner materials may require the finesse of TIG welding to avoid damage.

3. Available Equipment

Consider the welders you have access to. If you only have a MIG welder, it may still adequately suffice for typical exhaust repairs. However, if you have access to both, weigh the benefits of each based on your project’s specific needs.

Expert Tips for Welding Auto Exhausts

To achieve the best results while welding automotive exhaust components, consider these expert recommendations:

- Clean the Metal: Ensure that all surfaces are free of rust, oil, or other contaminants before welding to achieve strong joints.

- Proper Filler Material: Use a filler material compatible with the metals being joined, especially for dissimilar metals.

- Weld in a Ventilated Area: Welding generates fumes; therefore, working in a well-ventilated area is essential for safety.

- Practice Techniques: If you’re new to welding, practice on scrap pieces to hone your skills before tackling the actual exhaust system.

FAQs about Welding Auto Exhaust

What is the difference between MIG and TIG welding?

MIG welding uses a continuously fed wire electrode to create a weld, making it faster and easier for beginners, while TIG welding offers superior control and quality due to its non-consumable electrode, allowing for more precise welds.

Can I weld an exhaust system with a stick welder?

While possible, stick welding is not typically recommended for exhaust systems due to the difficulty in handling thin metals and the potential for producing more slag, which could affect weld quality.

What type of welder should I buy for occasional auto exhaust repairs?

A MIG welder is often the best option for hobbyists or those conducting occasional exhaust repairs, providing versatility and ease of use for varying metal types.

Is it necessary to use a special filler rod for stainless steel?

Yes, it’s important to use filler rods specifically designed for stainless steel to prevent contamination and ensure a strong, durable joint.

Conclusion

Choosing the right welder for auto exhaust systems is vital for achieving durable and efficient results. MIG welding stands out as the best all-around choice for its ease of use and efficiency, while TIG welding offers precision for special applications. By understanding the materials and the processes involved, you can ensure a high-quality and long-lasting exhaust repair, enhancing your vehicle’s performance and longevity.